- Product Details

- {{item.text}}

Quick Details

-

Processing Service:

-

CNC

-

Material:

-

Hot Pressed Boron Nitride

-

Purity:

-

99%

-

Color:

-

White

-

Density:

-

2.0g/cm3

-

Thermal Conductivity:

-

30 W/m.k

-

Thermal Expansion Coefficient:

-

1.5x10^(-6)/K

-

Volume Resistivity:

-

>10^(14) Ω.cm

-

Max Operation Temperature:

-

2100 C

Quick Details

-

Place of Origin:

-

Fujian, China

-

Model Number:

-

Customized

-

Brand Name:

-

WINTRUSTEK

-

Processing Service:

-

CNC

-

Material:

-

Hot Pressed Boron Nitride

-

Purity:

-

99%

-

Color:

-

White

-

Density:

-

2.0g/cm3

-

Thermal Conductivity:

-

30 W/m.k

-

Thermal Expansion Coefficient:

-

1.5x10^(-6)/K

-

Volume Resistivity:

-

>10^(14) Ω.cm

-

Max Operation Temperature:

-

2100 C

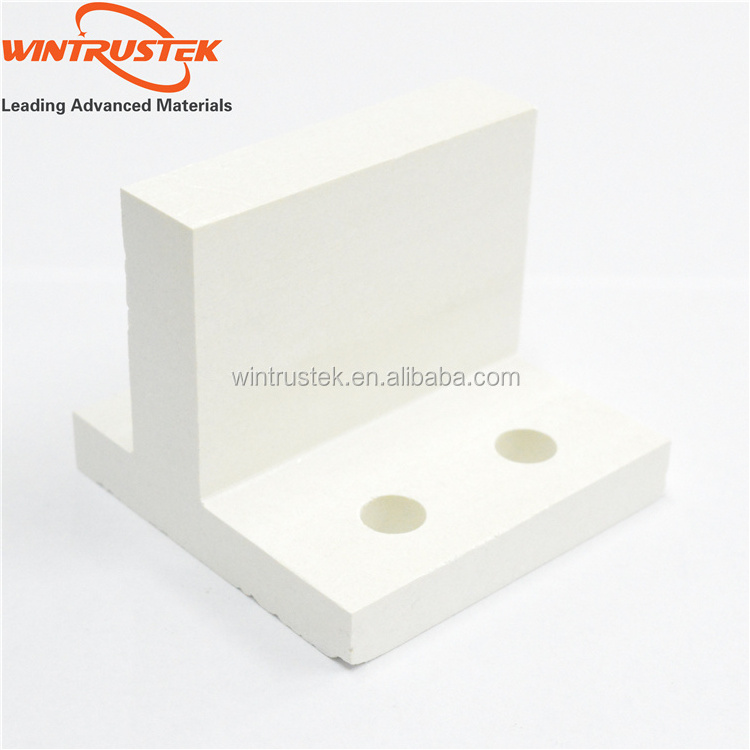

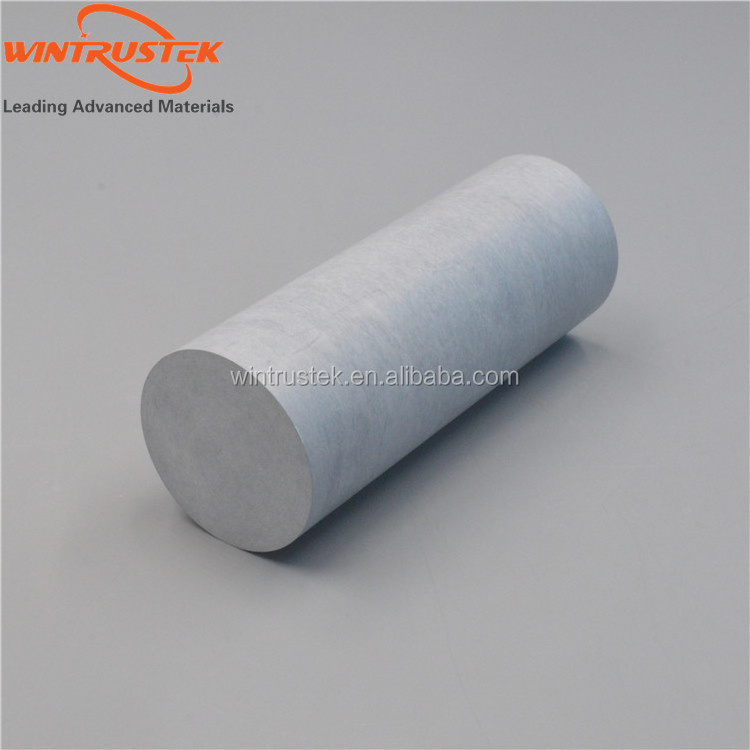

| - Material: | Hot Pressed Boron Nitride / HPBN |

| - Purity: | 99% |

| - Various Composite Solutions: |

BN99 ; BN+Ca ; BN+Si ; BN+Al2O3 ; BN+SiC ; BN+ZrO2 ; BN+AlN |

| - Typical Characteristics: |

1. Easily Machinable 2. High Volume Resistivity 3. Excellent Thermal Shock Resistance 4. Withstand Extreme High Temperature 5. Corrosion Resistant |

| - Typical Applications: |

1. High Temperature Insulation Parts 2. Thermocouple Protection Tube 3. Crucible for Melting Metal, Alloy, Rare Earth etc. 4. Crucible for Electron Beam Evaporation Deposition 5. Nozzle for Amorphous Soft Magnetic Strip 6. Nozzle for Metal Spraying and Magnetic Material Powdering 7. Evaporation Boat 8. Insulation Arc and Washer for PV and Polysilicon Ignot Furnace |

| Properties / Material | BN99 | BN+Ca | BN+Si | BN+Al2O3 | BN+SiC | BN+ZrO2 | BN+AlN | |

| Density (g/cm 3 ) | 2.00 | 2.10 | 2.25 | 2.35 | 2.50 | 3.00 | 2.60 | |

| Volume Resistivity (Ω.cm) | >10 14 | >10 13 | >10 12 | >10 12 | >10 12 | >10 12 | >10 13 | |

| Max Working Temp. (℃) | Air | 900 | 900 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Vacuum | 1900 | 1900 | 1700 | 1700 | 1700 | 1800 | 1800 | |

| Inert Gas | 2100 | 2100 | 1700 | 1700 | 1700 | 1800 | 1800 | |

| Flexural Strength (MPa) | 30 | 35 | 82 | 85 | 105 | 120 | 110 | |

| Compressive Strength (MPa) | 58 | 70 | 148 | 150 | 175 | 200 | 185 | |

|

Thermal Expansion Coefficient (10 -6 /K) |

1.5 | 1.6 | 1.8 | 1.9 | 4.0 | 30 | 55 | |

| Thermal Conductivity (W/mk) | 30 | 32 | 35 | 35 | 40 | 30 | 55 | |

I n your inquiry, please provide as detailed imformation as you can for our evaluation.

1. Material :

If you are not sure what exact material you need, please tell us your requests on material performance and your specific application, according to which we will offer you the most suitable material.

2. Drawing :

Please make sure the drawing is clear with all of your technical requests to get our offer at the soonest.

3. Quantity :

The last but not the least, don't forget to tell us the quantity so that we can quote our best price.