- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

other

-

Name:

-

mosquito coil making machine

-

Sieve plate size:

-

900mmx450mmx40mm

-

Raw material:

-

Bran powder, wood powder, charcoal powder

-

Motor total power:

-

27.65KW

-

Type:

-

Automatic

-

Capacity:

-

22680pcs/ h (in 18-mode as an example)

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZFTOPA

-

Weight (KG):

-

2000

-

Core Components:

-

other

-

Name:

-

mosquito coil making machine

-

Sieve plate size:

-

900mmx450mmx40mm

-

Raw material:

-

Bran powder, wood powder, charcoal powder

-

Motor total power:

-

27.65KW

-

Type:

-

Automatic

-

Capacity:

-

22680pcs/ h (in 18-mode as an example)

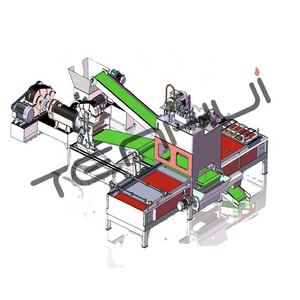

New Type Mosquito Repellent Incense Moulding Machine Automatic Mosquito Coil Making Machine

Product Description

The device is designed for all hydraulic equipment, photoelectric at the beginning of the use of PLC controlled automatic detection, structure simple, Operation and Maintenance Convenient and safe high-performance, easy replacement of mold, cylinder working stroke is short, and is equipped with high-density foam panels, chain transfer Ping Stable, non-vibration, high efficiency, small footprint.

On the basis of original 0ZWJ-1 8/111—A wholly automatic mosquito-repellent coil manufacture machine,this equipment is developed.And such product features rational design,adoption of imported famous PLC control circuit,imported display screen,automatic inspection of photoelectric switch,simple construction,small room occupation,integral motor and wholly hydraulic control,convenient operation and maintenance,reliable security performance,convenient mould change,molding from jacking pressure of oil cylinder,short service stroke of oil cylinder,and high production efficiency.And therefore,it is the first home-made advanced mosquito-repellent manufacture equipment,never crushing mosquito-repellent screen.

Specification

|

Model

|

ZFWXJ-18

|

|

Capacity

|

22680pcs/ h (in 18-mode as an example)

|

|

Motor total power

|

27.65KW

|

|

Operator

|

4 people

|

|

Sieve plate size

|

900mmx450mmx40mm

|

The Machine

production line

Finished Product

Paper mosquito

Describe of paper mosquito coil making machine:

1.The basis process of special paper, including leather recycled paper and Mosquito-repellent incense paper

2.Raw material is waste material of the horn side. all kinds of leather, leatwaste fibre, etc.

3.With special equipment, mixed with glue, made into pulp, then gas floating foudrinier craft, thickness between 0.6-5 mm (can be adjusted).

4.Low cost with high quality

5.High efficiency

6.Eco-friendly

Flow chart of paper mosquito coil making machine:

paper shaping machine ----cut paper --- dewater ---paper mosquito coil forming machine --- drying machine --- closing machine --- medical spraying machine --- packaging machine

Applications of paper mosquito coils making machine:

Used in the production of kraft paper, wrapping paper manufacturers.

Capacity : can make based on your require !

1.The basis process of special paper, including leather recycled paper and Mosquito-repellent incense paper

2.Raw material is waste material of the horn side. all kinds of leather, leatwaste fibre, etc.

3.With special equipment, mixed with glue, made into pulp, then gas floating foudrinier craft, thickness between 0.6-5 mm (can be adjusted).

4.Low cost with high quality

5.High efficiency

6.Eco-friendly

Flow chart of paper mosquito coil making machine:

paper shaping machine ----cut paper --- dewater ---paper mosquito coil forming machine --- drying machine --- closing machine --- medical spraying machine --- packaging machine

Applications of paper mosquito coils making machine:

Used in the production of kraft paper, wrapping paper manufacturers.

Capacity : can make based on your require !

Features of paper mosquito coils making machine:

1. Square wimble pipe for pulp entering system ;

2. Pressure headbox and stainless steel cylinder mold forming system ;

3. Prepress and main press section dewater system ;

4. Big diameter and group dryers for drying system ;

1. Square wimble pipe for pulp entering system ;

2. Pressure headbox and stainless steel cylinder mold forming system ;

3. Prepress and main press section dewater system ;

4. Big diameter and group dryers for drying system ;

5.Air automatic control guider and electric stretcher for belt

6. producing printing/copying/writing paper;

7. high efficiency and high quality paper;

8. easy-controled and energy saving

9. To produce the paper smooth and fine

6. producing printing/copying/writing paper;

7. high efficiency and high quality paper;

8. easy-controled and energy saving

9. To produce the paper smooth and fine

video

Hot Searches