- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OTS

-

Model Number:

-

XB-OTS-208A

-

Vibration Mode:

-

Vibration (Vertical and Horizontal)

-

Amplitude Range:

-

25.4mm(1 Inch) Meet Ista/En71

-

Max .Load:

-

60kg (Can Be Customized)

-

Working Table Size:

-

1400*1200*1940 mm L*W

-

uses:

-

Vibration testing machine

-

Control Frequency Range:

-

350*350*1100 mm

-

Transmit Approach:

-

60~300rpm Cycle/Min (Adjustable)

-

Design Criteria:

-

25 ~ 40km / H

-

Standard:

-

En71,ANSI,ASTM Ista

-

Delivery Time:

-

15 Days After Receive The Deposit

Quick Details

-

Warranty:

-

14 months

-

Power:

-

Electronic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OTS

-

Model Number:

-

XB-OTS-208A

-

Vibration Mode:

-

Vibration (Vertical and Horizontal)

-

Amplitude Range:

-

25.4mm(1 Inch) Meet Ista/En71

-

Max .Load:

-

60kg (Can Be Customized)

-

Working Table Size:

-

1400*1200*1940 mm L*W

-

uses:

-

Vibration testing machine

-

Control Frequency Range:

-

350*350*1100 mm

-

Transmit Approach:

-

60~300rpm Cycle/Min (Adjustable)

-

Design Criteria:

-

25 ~ 40km / H

-

Standard:

-

En71,ANSI,ASTM Ista

-

Delivery Time:

-

15 Days After Receive The Deposit

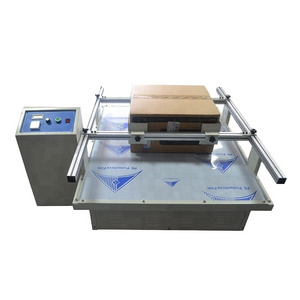

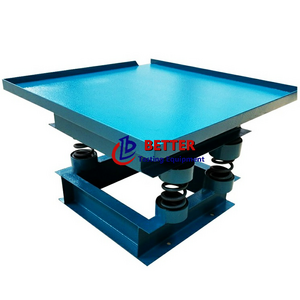

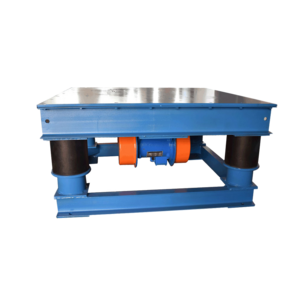

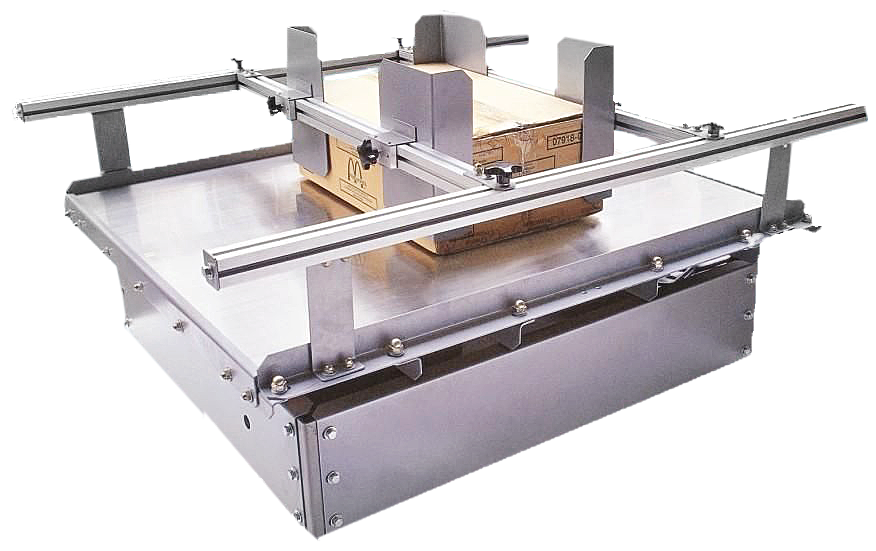

Simulation Transport Vibration Table

This product is for a variety of packaging materials, PC boards, electrical products . as well as the simulated transport vibration test of the packaged products, to assess the degree of vibration-resistance.... simulate the transport process Caused damage because of the vibration force, the test results can be used as the reference of the design packaging.

Features:

1. Low price, the price is only 10% of similar products in the United States;

2. Digital instrument display vibration frequency;

3. Synchronous mute belt drive;

4. The specimen is clamped with rail, easy to operate, safe;

5. The base of the machine adopts heavy-duty trench with damping pad, easy installation, smooth operation, no need to install the foot screw;

6. DC motor speed, smooth operation, strong load capacity;

7. Rotary vibration (commonly known as racing), in line with European and American transport standards;

Design standards: ASTM, ISTA

|

Frequency range

|

60~300RPM cycle/min (Adjustable)

|

|

|

Vibration mode

|

Rotary vibration (Vertical and horizontal)

|

|

|

Amplitude range

|

25.4mm(1 inch) meet ISTA/EN71

|

|

|

Max .Load

|

100KG

|

|

|

Accuracy Grade

|

0.5

|

|

|

Simulation speed

|

25 ~ 40km / h

|

|

|

Working Table size

(L*W, mm) |

1000*1200 mm

|

|

|

Digital speed

|

Accuracy is not greater than ± 3 rev / min

|

|

|

Work time setting range

|

0~999H99M

|

|

|

Speed display accuracy

|

1RPM cycle/min

|

|

|

Motor Power

|

1HP

|

|

|

Max.current

|

5A

|

|

|

Power

|

1 phase 220V 50Hz/60Hz

|

|

|

Overall dimensions

|

1255*1070*660 mm

|

|

|

Machine weight

|

125kg

|

|

|

Environmental conditions

|

temperature: 5 ~ 40 ℃, relative humidity ≤ 85%

|

|

|

Speed control mode

|

DC speed control or AC frequency control

|

|

|

*** Standard: ASTM-D999(A1&A2) ISTA PROJECT 2A

|

|

|

Analog Transport Vibration Test Bench Test Standard Requirements for Equipment:

1. ISTA test standard is the American Transportation Association standard

2. ASTM test standards are American Materials Association standards

Two standard requirements for simulated transport vibration are:

1. Amplitude is 25.4mm (1 inch, fixed)

2. Frequency 1.5-5Hz (or 100-300 r / min adjustable)

3. The test basis is: T = 14200 / CPM (based on the total number of vibration is 14200 times)

ISTA / ASTM standards related test methods table:

|

Test Speed (CPM)

|

Corresponding frequency (Hz)

|

testing time (M)

|

|

150

|

2.5

|

95

|

|

180

|

3.0

|

79

|

|

210

|

3.5

|

68

|

|

240

|

4.0

|

59

|

|

270

|

4.5

|

53

|

|

300

|

5.0

|

47

|

Advantage

Ø 24 hours online

Ø 35 years experiences

Ø Sample chamber of each model

Ø Best price, fast delivery

Ø OEM,ODM

Ø Oversea offices

Ø Own import and export business license

ØISO,CE,UL,ASTM,DIN,EN,GB,BS,JIS,ANSI,TAPPI,AATCC,IEC,VDE

Ø 35 years experiences

Ø Sample chamber of each model

Ø Best price, fast delivery

Ø OEM,ODM

Ø Oversea offices

Ø Own import and export business license

ØISO,CE,UL,ASTM,DIN,EN,GB,BS,JIS,ANSI,TAPPI,AATCC,IEC,VDE

Customer Support Services

Ø Installation

Ø Training (Training customer employees)

Ø Calibration

Ø Preventative maintenance

Ø Replacement parts

Ø Assistance via phone or internet

Ø On-site diagnosis and repair/online diagnosis and repair

Ø Training (Training customer employees)

Ø Calibration

Ø Preventative maintenance

Ø Replacement parts

Ø Assistance via phone or internet

Ø On-site diagnosis and repair/online diagnosis and repair

Recommend Products

Hot Searches