- Product Details

- {{item.text}}

Quick Details

-

Printing Type:

-

All type printing machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JCTPRINT

-

Color:

-

Grey

-

Rated torque:

-

6, 12, 25, 50, 100, 200

-

Cooling Way:

-

Automatic Cooling, Air Cooling

-

Speed:

-

800, 1000 r/min

-

Package:

-

Carton, as your requirements

-

Voltage:

-

24V

-

Related product:

-

Magnetic clutch, tension controller

-

MOQ:

-

1 Piece

Quick Details

-

Condition:

-

New

-

Type:

-

Magnetic powder brake

-

Use:

-

All brand printing machine

-

Printing Type:

-

All type printing machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JCTPRINT

-

Color:

-

Grey

-

Rated torque:

-

6, 12, 25, 50, 100, 200

-

Cooling Way:

-

Automatic Cooling, Air Cooling

-

Speed:

-

800, 1000 r/min

-

Package:

-

Carton, as your requirements

-

Voltage:

-

24V

-

Related product:

-

Magnetic clutch, tension controller

-

MOQ:

-

1 Piece

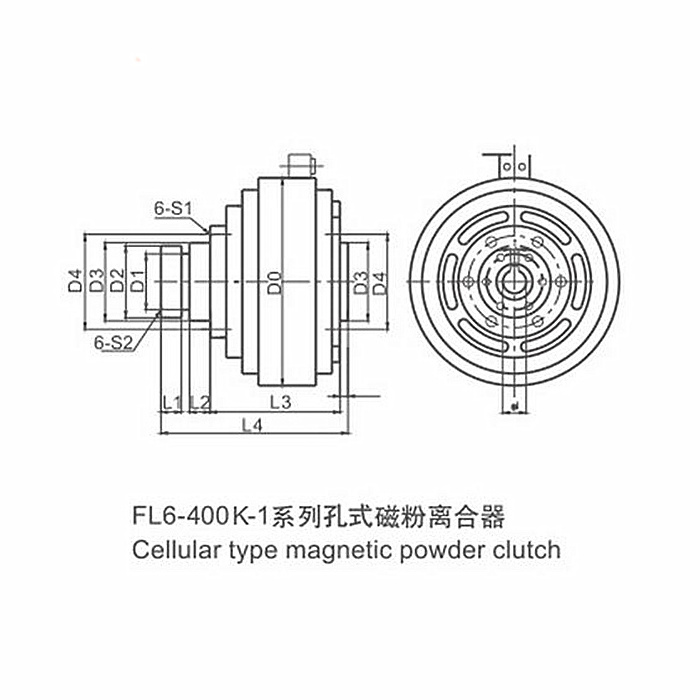

Automatic web tension controller for magnetic powder clutch/brake

Working principle of magnetic powder brake:

1. The magnetic powder brake is a new type of transmission component that uses magnetic powder as a medium to form a magnetic powder chain to transmit torque under energization, and is mainly composed of an inner rotor, an outer rotor, an excitation coil and a magnetic powder.

2. When the coil is not energized, the active rotor rotates. Due to the centrifugal force, the magnetic powder is clamped on the inner wall of the active rotor, and there is no contact between the magnetic powder and the driven rotor, and the active rotor idles.

3. After the DC power supply is turned on, an electromagnetic field is generated, and the magnetic powder of the working medium forms a magnetic powder chain under the action of the magnetic force line, and the inner rotor and the outer rotor are coupled to achieve the purpose of transmission and braking torque.

Application of magnetic powder brake :

*Textile Machinery: Fiber twisting machine, processor, loom

*Metal fishing system: extruder, wire stretcher, press, welding machine, wire reel, cutting machine, pipe manufacturer, winding machine

* Machine tool system: lathe,

* Milling machine, steel extrusion machine, CNC lathe, special machinery

*Transport equipment: crane, feeder, conveyor, road roller, winder

*Paper system: bag making machine, box making machine, paper cutting machine, book making machine, paper cutting machine, copy paper machine

Specification:

Models and specifications of magnetic powder brake

1)Hollow type cellular shaft magnetic powder brake

|

Modle |

Torque(N.m) |

Current(A) |

Votage(V) |

Rotation speed

|

Weight(kg) |

|

FZ 6K- 3 |

6 |

0.8 |

24 |

1000 |

3 |

|

FZ 12K- 3 |

12 |

1 |

24 |

1000 |

4.5 |

|

FZ 25K- 3 |

25 |

1.5 |

24 |

1000 |

7.5 |

|

FZ 50K- 3 |

50 |

1.8 |

24 |

1000 |

12 |

|

FZ 100K- 3 |

100 |

2 |

24 |

800 |

20.5 |

|

FZ 200K- 3 |

200 |

3 |

24 |

800 |

30 |

2)Singel shaft type magnetic powder brake

|

Modle |

Torque(N.m) |

Current(A) |

Votage(V) |

Rotation speed

|

Weight(kg) |

|

FZ 6A-1 |

6 |

0.8 |

24 |

1400 |

3.5 |

|

FZ 12A-1 |

12 |

1 |

24 |

1400 |

6 |

|

FZ 25A-1 |

25 |

1.5 |

24 |

1400 |

8 |

|

FZ 50A-1 |

50 |

1.8 |

24 |

1400 |

14 |

|

FZ 100A-1 |

100 |

2 |

24 |

1000 |

28 |

|

FZ 200A-1 |

200 |

2.5 |

24 |

1000 |

50 |

|

FZ 400A-1 |

400 |

3 |

24 |

1000 |

75 |

And we also have other type magnetic powder brakes: Japanese type magnetic powder brakes.

Advantages of magnetic powder brake:

1. Fast response. Dry design means instant reaction to commands.

2. Durability. Excellent heat dissipation and quality materials mean long life, even under high frequency and high performance conditions.

3. Easy to install and maintain. Sealed bearing race eliminates the need for removal of the center core. No dust brush is needed, and operation is simper and easier.

4. No need to adjust the motor. The motor is designed so that it does not need adjustment of the friction surface, and once it is installed only very minor adjustments are needed.

5. Adjustable torque. Torque levels can be increased or decreased by changing the current, making it suitable for a variety of applications.

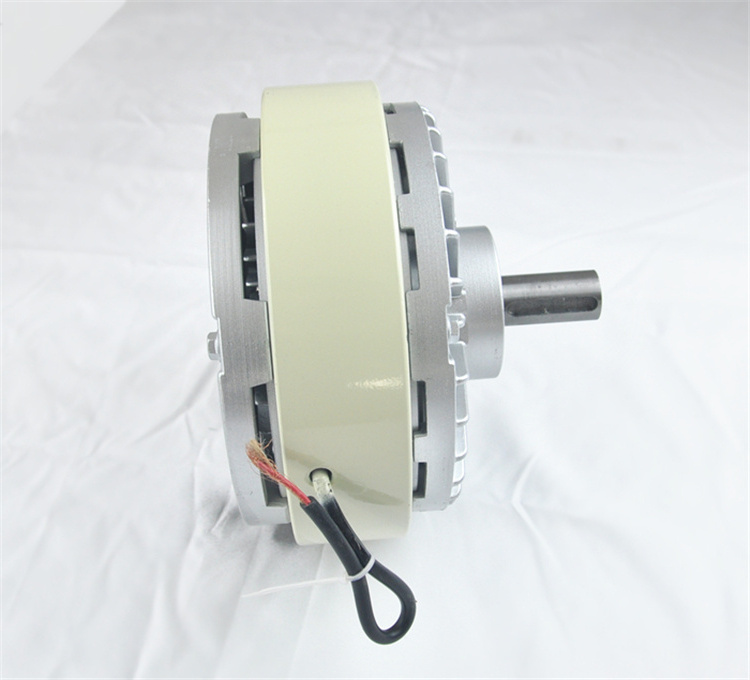

The magnetic powder clutch:

The tension controller:

Manual tension controller

Auto tension controller:

We will choose the suitable package according to the weight of the goods.

The shipment:

It depends to your requirements.

Our Service:

1. Perfect service system and after-sale protection

2. Quality assurance, one year warranty.

3. Support professional matched other equipments.

4. Unique development and design capabilities to meet the needs of special-purpose equipment manufacturing.

5. Complete specifications, cost-effective and spot supply.