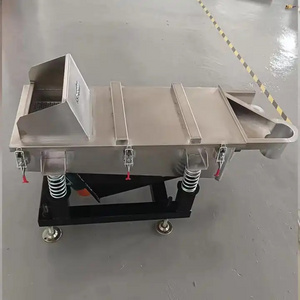

Ultrasonic vibrating sieve machine suitable to sieve power, which is light density, low humidity, easy adhesion or a static of the powder and super fine powder, and improve the sieving efficiency. It is widely used in carbonize silicon, alloy powder, tungsten

powder, aluminum powder, rubbing powder etc. It can completely solve the difficult technology problems that other screening

machines cannot solve.

- Product Details

- {{item.text}}

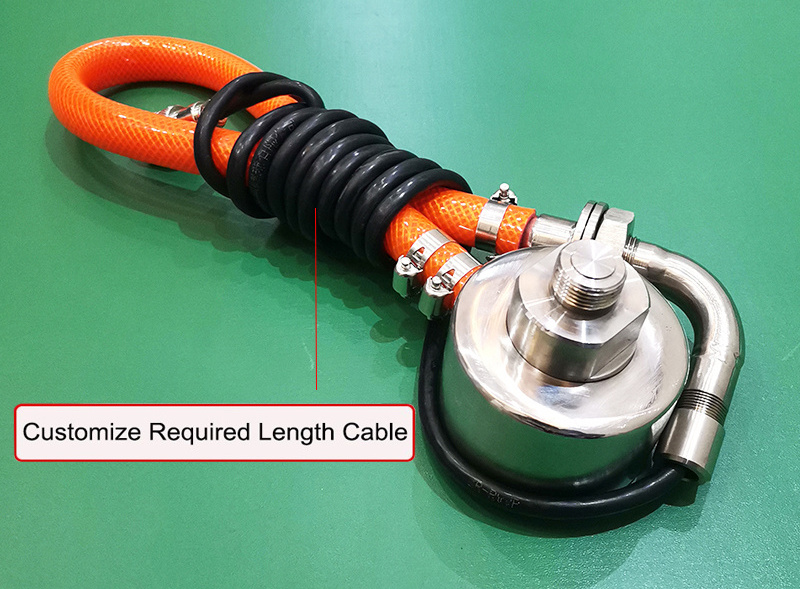

Quick Details

-

Weight:

-

7

-

Product name:

-

Ultrasonic Vibrating Screen Transducer

-

Application:

-

Screen, ultrasonic vibration screen transducer

-

Material:

-

Stainless Steel, aluminum

-

Frequency:

-

33KHZ

-

Resonance Impedance:

-

20-40

-

Input Power:

-

100W

-

Static Capacity:

-

5000

Quick Details

-

Place of Origin:

-

Beijing, China

-

Core Components:

-

Ultrasonic Sieve Vibrator Screen Transducer

-

Power:

-

200, 300W

-

Weight:

-

7

-

Product name:

-

Ultrasonic Vibrating Screen Transducer

-

Application:

-

Screen, ultrasonic vibration screen transducer

-

Material:

-

Stainless Steel, aluminum

-

Frequency:

-

33KHZ

-

Resonance Impedance:

-

20-40

-

Input Power:

-

100W

-

Static Capacity:

-

5000

Product Overview

vibration screen ultrasonic transducer

The function of Ultrasonic Vibrating Screen Transducer for fine Powder Screen

1:

Achieve high precision and high mesh screening at the same time,control a narrow particle size range.

2:Can be single layer and multi-layer.

3:Screen self-cleaning function:greater than 500 mesh sieve,no mesh plug,no attenuation screening efficiency.

4:Solve the strong adsorption,easy to reunite,electrostatic,high precision,high density,high light specific gravity and other screening problem.

5:Screening precision can be improved 1-100%, yield can increase 0.5 to 10 times.

2:Can be single layer and multi-layer.

3:Screen self-cleaning function:greater than 500 mesh sieve,no mesh plug,no attenuation screening efficiency.

4:Solve the strong adsorption,easy to reunite,electrostatic,high precision,high density,high light specific gravity and other screening problem.

5:Screening precision can be improved 1-100%, yield can increase 0.5 to 10 times.

Product Picture

&

If you are interested in our product.

& Pls just feel free to send us your inquiry.

& We wil try our best to quote the competitive price for you!----- Contact Us Now

& Pls just feel free to send us your inquiry.

& We wil try our best to quote the competitive price for you!----- Contact Us Now

|

Type

|

Frequency(KHz)

|

Input Power(W)

|

Transducer Suggest

|

|

QXUWVT33-100

|

33KHz-55KHz

|

100

|

1 Piece

|

|

QXUWVT33-200

|

33KHz-55KHz

|

200

|

2 Piece

|

|

QXUWVT33-300

|

33KHz-55KHz

|

300

|

2-3 Piece

|

Technical Characteristics

1. Stable and reliable 2 . Firm and durable 3. High efficiency 4. Long service life

1. Stable and reliable 2 . Firm and durable 3. High efficiency 4. Long service life

Product Usage Scenarios

Some Application of Ultrasonic Vibrating Screen Transducer for fine Powder Screen

Chemical industry:resin, coatings, industry, medicine, cosmetics, paint, powder, etc.

Food industry:sugar powder, starch, salt, rice flour, milk powder, soybean milk, egg powder, soy sauce, juice,

etc.

Metal, metallurgy, mining, aluminium powder, lead powder, copper powder, ore, electrode powder, alloy powder, manganese dioxide, electrolytic copper powder, electric magnetic material, polishing powder, refractory material, kaolin, lime, alumina,heavy calcium carbonate, quartz sand, etc.

Pollution treatment, waste oil, waste water, dyeing wastewater, additives, activated carbon, etc

Application Range

Related Products

Hot Searches