- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

2900*1600*1900mm

-

Weight (KG):

-

2800

-

Power (kW):

-

30w

-

Name:

-

Mattress pocket spring coiling production making machine

-

Keyword:

-

pocket spring mattress

-

Key words:

-

pocket spring

-

Frequency:

-

50/60Hz

-

Productivity:

-

130Spring/min

-

Non-woven width:

-

320-680mm

-

Bag height:

-

80-250mm

-

Function:

-

mattress spring making machine

-

Kw:

-

spring coiling machine

-

Product name:

-

pocket spring production line

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Share

-

Marketing Type:

-

New Product

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

2900*1600*1900mm

-

Weight (KG):

-

2800

-

Power (kW):

-

30w

-

Name:

-

Mattress pocket spring coiling production making machine

-

Keyword:

-

pocket spring mattress

-

Key words:

-

pocket spring

-

Frequency:

-

50/60Hz

-

Productivity:

-

130Spring/min

-

Non-woven width:

-

320-680mm

-

Bag height:

-

80-250mm

-

Function:

-

mattress spring making machine

-

Kw:

-

spring coiling machine

-

Product name:

-

pocket spring production line

Products Description

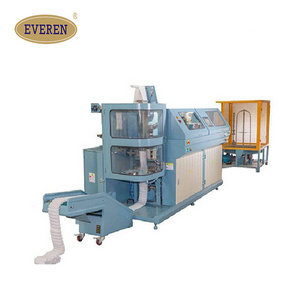

Mattress Pocket Spring Coiling Production Making Machine

|

Model

|

SR-KD THJ

|

|

Speed

|

130pcs/min

|

|

Height

|

100-250mm

|

|

Diameter

|

Ø60- Ø75mm

|

|

Wire

|

Ø1.6 - Ø2.2mm

|

|

Voltage

|

380V, 50HZ, 3 phases

|

|

power

|

15kw

|

|

Air

|

0.6Mpa

|

|

Size

|

7350*1420*1930mm

|

|

Weight

|

3500kg

|

1. The wire frame conveying adopts frequency converter control, the speed can be directly changed in the computer at any time, the speed is simple, the maximum conveying weight is 1000KG.

2. Mature CNC spring winding machine head, digital control of spring shape, computer can be stored in a variety of specifications of spring, convenient specification conversion.

3. Frequency converter to feed cloth, effectively reduce the burst rate, and equipped with the function of feeding cloth, save time and material.

4. Titanium alloy ultrasonic mold, strong and durable. Full intelligent real-time fault monitoring, safe and reliable.

6. Bus control system makes the whole machine more pliable and smooth.

7. The task mode can be set, and the machine will stop automatically when the task is completed, effectively reducing waste.

Details Images

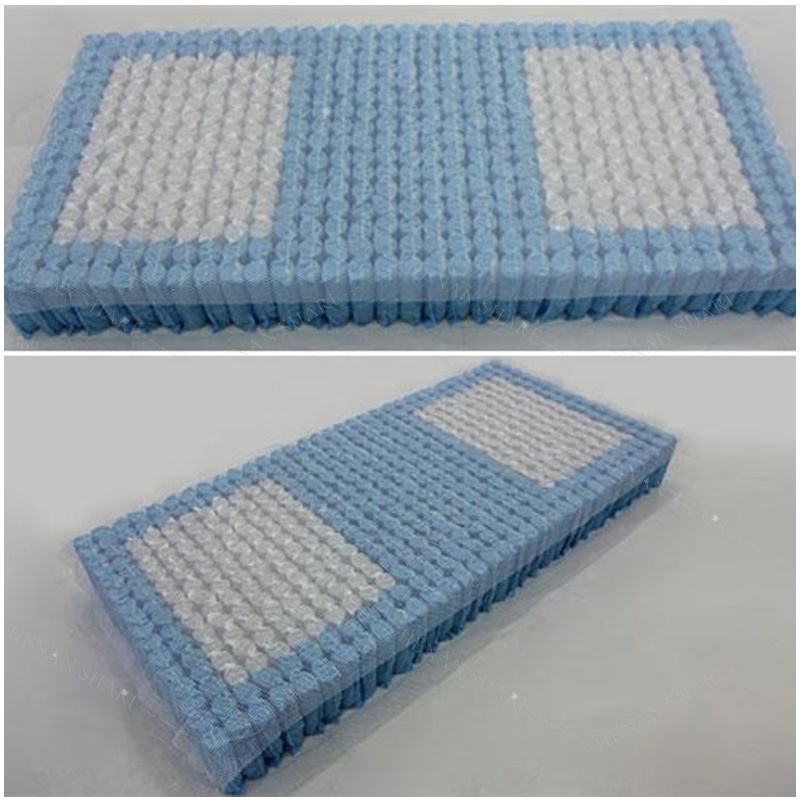

Product packaging

Hot Searches