- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

OEM casting parts

-

Material:

-

Stainless steel, Carbon steel, Alloy steel, or other materials

-

Mold:

-

Design, Fabrication, Test, Maintenance

-

Process:

-

Investment casting,lost wax casting,precision forging, machining

-

Surface Treatment:

-

Anodisation, Polishing, Plating, Powder Coating, Sand Blasting etc.

-

Tolerance:

-

+- 0.005mm

-

Inspection Tool:

-

Spectrometer UT, Caliper, Depth Caliper R gauge, CMM, etc.

-

Serving Industry:

-

Auto, Machinery, Medical Equipment, Electronic, Electrical, Household

-

Service:

-

OEM&ODM

-

Machining Process:

-

CNC Finishing Process

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Suntech

-

Model Number:

-

Casting

-

Product Name:

-

OEM casting parts

-

Material:

-

Stainless steel, Carbon steel, Alloy steel, or other materials

-

Mold:

-

Design, Fabrication, Test, Maintenance

-

Process:

-

Investment casting,lost wax casting,precision forging, machining

-

Surface Treatment:

-

Anodisation, Polishing, Plating, Powder Coating, Sand Blasting etc.

-

Tolerance:

-

+- 0.005mm

-

Inspection Tool:

-

Spectrometer UT, Caliper, Depth Caliper R gauge, CMM, etc.

-

Serving Industry:

-

Auto, Machinery, Medical Equipment, Electronic, Electrical, Household

-

Service:

-

OEM&ODM

-

Machining Process:

-

CNC Finishing Process

Product Description

ADVANTAGES OF DIE CASTING

1. Low Part Cost

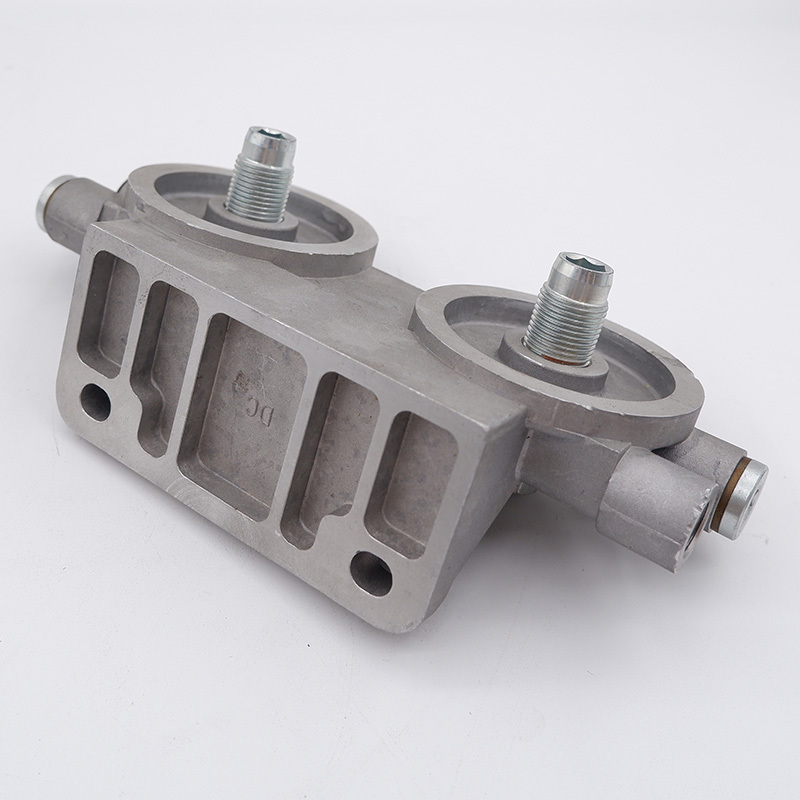

Die cast parts are very low cost compared to other methods - Higher volumes equal lower costs. casting motor cover

2. Excellent Repeatable Dimensional Accuracy

Castings have an excellent repeatable dimensional accuracy, thanks to the strength of the tooling.

3. Excellent Machinability

Castings are easy to machine and offer a great amount of options.

4. Excellent Finishing Properties

Castings can be finished with a vast amount of processes, including powder coating, plating and many more.

|

Casting Type

|

High Pressure Die Casting casting motor cover

|

|

Material

|

|

|

Casting Mold

|

Design, Fabrication, Test, Modification & Maintenance

|

|

Surface Treatment

|

Sanblasting, Polishing, Plating, Powder Coating, Anodisation etc

|

|

Accuracy

|

Class CT4~CT11

|

|

Surface Roughness

|

Ra1.6~Ra6.3

|

|

Certificate

|

ISO 9001:2015

|

|

Cavity

|

Single or multiple

|

|

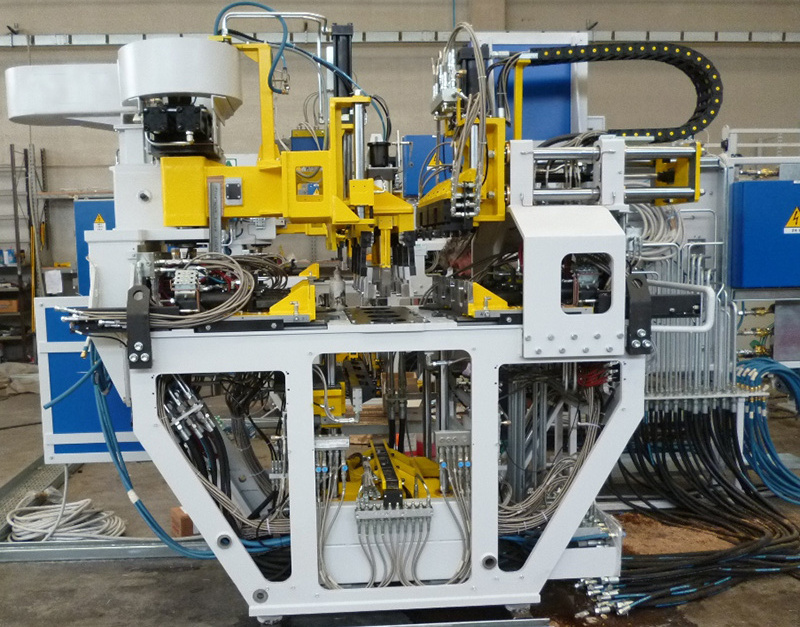

Casting Machine

|

1800KN-12000KN

|

|

Mold Life Time

|

50K - 150K times

|

|

Size

|

1) According to customers' drawings

2) According to customers' samples |

|

Drawing Format

|

PDF, DWG, DXF,IGS, STP, X_T etc.

|

|

Payment Term

|

T/T, L/C,D/A,D/P,Western Union,MoneyGram,paypal

|

|

Testing Machine

|

Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on

|

|

Quality Control

|

ISO/TS16949:2002 and ISO14001:2004 system

|

|

Piece weight

|

1 g - 20 kg

|

|

Pie

ce thickness

|

≥ 0.5mm

|

|

Standards

|

GB, ASTM, SAE, ISO, EN, DIN, JIS, BS

|

|

Company advantages

|

Design to Finished Products

We provide complete die casting products, including 3D flow analysis, high pressure die casting, trimming, hand cleaning, drilling, tapping, machining, vibratory finishing, shot blasting, satin sanding, painting, powdercoating, E coating, anodizing, polishing, plating, coating, bar coding, assembly and packaging. We provide our customers with high quality castings made in the China at competitive prices and on-time delivery. High Quality Castings We consistently, efficiently and effectively produce high quality precision aluminum castings and zinc castings with consistent surface finishes for our customers.We use our many years of knowledge and experience in die casting to produce high quality aluminum castings and zinc castings that meet the fit, form and function and on time delivery requirements of our customers. |

Production Flow Chart

Packing & Delivery

Good quality plastic bag, bubble wrap, liner, paper carton, wooden case, pallet etc

Hot Searches