- Product Details

- {{item.text}}

Quick Details

-

size:

-

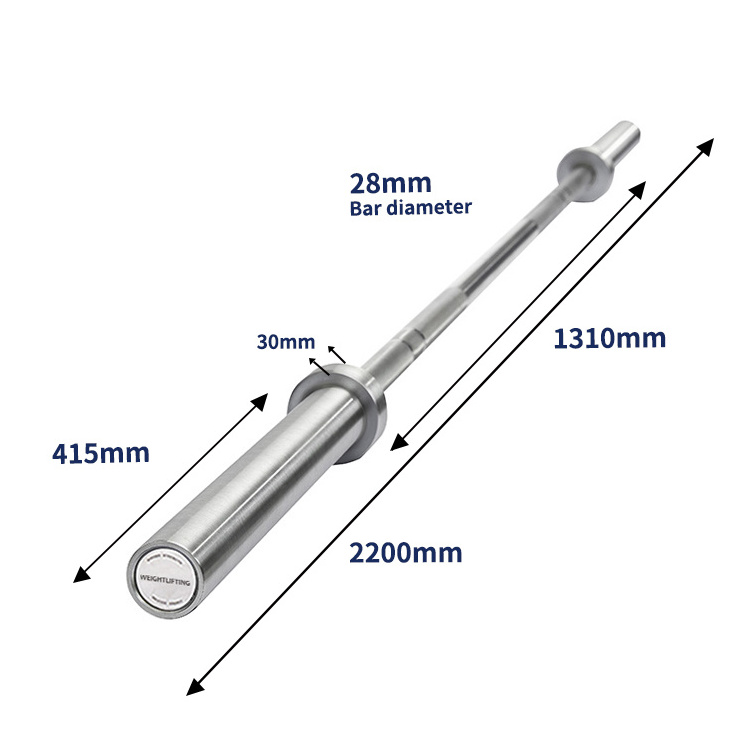

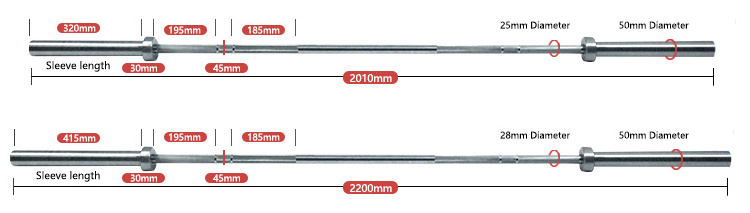

28*2200mm

-

Material:

-

Spring Steel

-

Surface Treatment for bar:

-

Hard Chrome

-

Surface Treatment for sleeve:

-

Hard Chrome

-

Max load:

-

1500LB

-

Bearings:

-

8 Needle Bearings

-

Size of Knurling:

-

P 1.2 Volcanic

-

Depth of Knurling:

-

0.25-0.35

-

Tensile Strength:

-

215KPSI

-

Packing:

-

Each barbell in a 6mm paper tube packing, 50pcs/plywood case

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ROUSER

-

Model Number:

-

TR-SP-HH-28

-

size:

-

28*2200mm

-

Material:

-

Spring Steel

-

Surface Treatment for bar:

-

Hard Chrome

-

Surface Treatment for sleeve:

-

Hard Chrome

-

Max load:

-

1500LB

-

Bearings:

-

8 Needle Bearings

-

Size of Knurling:

-

P 1.2 Volcanic

-

Depth of Knurling:

-

0.25-0.35

-

Tensile Strength:

-

215KPSI

-

Packing:

-

Each barbell in a 6mm paper tube packing, 50pcs/plywood case

Product Information

Experience a new level of training with our innovative training bar! Utilizing patented sleeve technology, our bar ensures enhanced stability and reduced rotation for a focused and effective workout. With reliable packaging, rest easy knowing your purchase will arrive undamaged. Customize your bar with preferred colors, logos, and patterns, making it uniquely yours. Elevate your fitness journey – purchase our personalized training bar for improved results and an enjoyable training experience!

|

Code

|

TR-SP-HH-28

|

Warranty

|

3 years

|

|

Length

|

2200mm/86.61 in.

|

Weight

|

20kg /44.09 lbs

|

|

Sleeve Surface

|

Hard Chrome

|

Grip Surface

|

Hard Chrome

|

|

Bearings and Bushings

|

Needle bearings

|

Grip Marking

|

Weightlifting

|

|

Knurling

|

P1.2 Volcanic

|

Max Load

|

680kg /1500lbs

|

|

Grip Diameter

|

28mm /1.1 in.

|

Sleeve Diameter

|

50mm /1.97 in.

|

|

Loadable Sleeve Length

|

415mm /16.34in.

|

Flange Width

|

30mm /1.18 in.

|

Products Detail

The bushing is patented. Increase the stability of the sleeve and improve the safety of the bar.

Surface Treatment:The delay in salt spray testing can be more than

72 hours.

Delicately packed

Tight and reliable packaging is used to provide protection during transportation.

Production Process

1. RAW MATERIAL

We have 1000 square meters of raw material warehouses, and we keep more than 200 tons of raw materials in stock for each model all year round, which will greatly avoid the fluctuation of product prices due to raw material costs.

2. HEAT TREATMENT

We have advanced heat treatment equipment imported from the United States. The engineers will choose the temperature according to different materials and control the hardness of raw materials during the production process.

3. HARDNESS TEST

We will sample and test each batch to ensure that the hardness of the product meets the process standards.

4. KNURLING

Our engineers can customize knurling patterns to meet your needs. All patterns are polished by hand after knurling.

5. STRAIGHTENING

Our engineers strictly control the straightness error of the products within 0.3mm.

6. FLAW DETECTION

We will take thorough examination for any defects and cracks of the products with our equipment.

7. SURFACE TREATMENT

Our finishes are professionally tested and we can provide a 72-hour salt spray test report.

8. Quality Control

We have a professional quality inspection team to ensure that the products will not have quality problems during transportation and use.

9. PACKING

We support you to customize any packaging. If you choose default packing we will use 6mm thick carton with a high strength plastic to secure the end, this will prevent the barbell bar from falling off during transit.

Customization Process

Hot Searches