- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Advisory Service

-

Dimension(L*W*H):

-

Advisory Service

-

Weight:

-

1500

-

Name:

-

Rotational Molding Machine

-

Product Type:

-

Tanks

-

Function:

-

Water tank making

-

Production time:

-

45 days

-

Control systerm:

-

Touch Interface

-

Color:

-

Custom made

-

MOQ:

-

1 Set

-

Arm style:

-

Offset Arm

-

Certification:

-

CE,ISO9001

-

After-sales Service:

-

online

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

yingchuang

-

Voltage:

-

22V,380V,440V

-

Power:

-

Advisory Service

-

Dimension(L*W*H):

-

Advisory Service

-

Weight:

-

1500

-

Name:

-

Rotational Molding Machine

-

Product Type:

-

Tanks

-

Function:

-

Water tank making

-

Production time:

-

45 days

-

Control systerm:

-

Touch Interface

-

Color:

-

Custom made

-

MOQ:

-

1 Set

-

Arm style:

-

Offset Arm

-

Certification:

-

CE,ISO9001

-

After-sales Service:

-

online

Product Description

Basic Processing Steps

(1).Charging the Mould (2).Heating the Mould (3).Cooling (4).Demoulding

1, Poura certain amount of powder raw materials into the mold, and merge the mold with screws or clamps.

2,Heat the mold and rotate it at 360 degrees in the oven; the raw material melts in the mold at 230-300degrees Celsius and evenly adheres to the inner surface of the mold to form the desired shape; heating time depend on the mould material,shape, weight and the raw material types.

3,At a certain time. after the heating is completed, the arm moves to the cooling station to start cooling,usually using air cooling and water mist cooling.When the mold surface is cooled to 80-90 degrees Celsius.

4,Stop the rotation of the arm and open the mold to complete molding process.

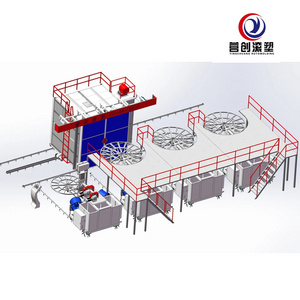

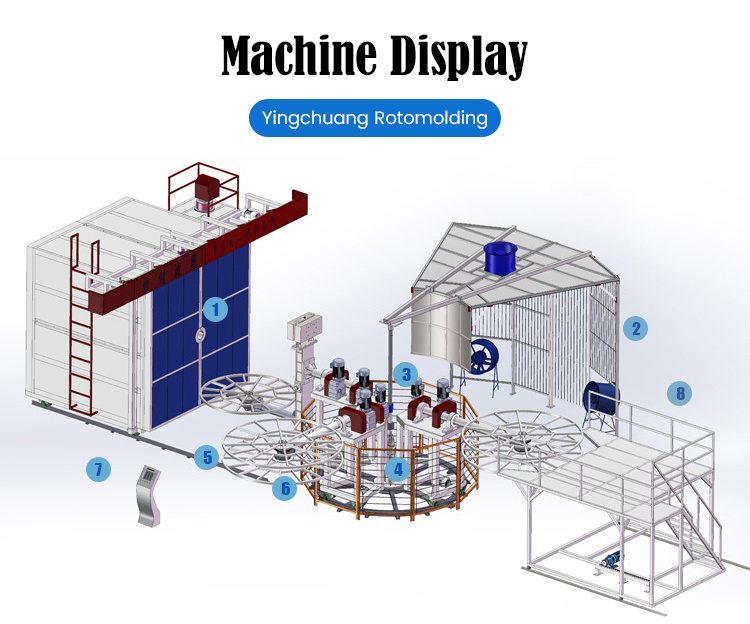

CAROUSEL ROTOMOLDING MACHINE

This machine maximum reliability and simplicity in use. An ideal machine for high volume production of articles, even of different sizes with similar working cycles. Sturdy construction a minimum maintenance are its principal features.

It can be equipped on request with 3 or 4 arms that change station simultaneously, so alternating in the different phases. Many cycle customising possibilities (double loading/unloading station, pre-cooling etc.

Specification

|

Model No

|

Floor Size

|

|

|

|

Biggest tank made

|

|||

|

|

L(m)

|

W(m)

|

H(m)

|

Operation platform

|

|

|||

|

CC-3A-1000

|

6.5

|

5

|

2.3

|

×

|

150L

|

|||

|

CC-3A-1600

|

9

|

7.5

|

3.1

|

×

|

500L

|

|||

|

CC-3A-2000

|

10

|

8

|

3.6

|

×

|

1000L

|

|||

|

CC-3A-2500

|

15

|

9

|

4.6

|

√

|

2500L

|

|||

|

CC-3A-3000

|

16

|

11

|

5

|

√

|

4500L

|

|||

|

CC-3A-3500

|

18

|

11

|

5.5

|

√

|

7000L

|

|||

|

CC-3A-4000

|

19.5

|

14

|

6.2

|

√

|

10000L

|

|||

|

CC-3A-4500

|

22

|

15

|

6.8

|

√

|

14000L

|

|||

|

Model No

|

Floor size

|

|

|

|

Biggest tank made

|

|||

|

|

L(m)

|

W(m)

|

H(m)

|

Operation platform

|

|

|||

|

CC-4A-2000

|

11

|

9

|

3.8

|

×

|

1000L

|

|||

|

CC-4A-2500

|

14

|

10

|

4.5

|

√

|

2500L

|

|||

|

CC-4A-3000

|

17

|

11

|

5.3

|

√

|

4500L

|

|||

|

CC-4A-3500

|

18

|

13

|

6

|

√

|

7000L

|

|||

|

CC-4A-4000

|

21

|

15

|

6.5

|

√

|

10000L

|

|||

|

CC-4A-4500

|

22.5

|

17

|

7

|

√

|

14000L

|

|||

Hot Searches