- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≥99%

-

Applicable Industries:

-

Veterinary, Cosmetics, Medical

-

Place of Origin:

-

China

-

Weight:

-

860 KG, 860kg

-

Voltage:

-

220V50Hz

-

Motor Power:

-

4.2KW

-

Filling speed:

-

5-20BPM

-

Filling accuracy:

-

±1%-1.5%

-

Vacuum pumping rate:

-

80m³/hour

-

Filling volume:

-

1ml

-

Filling nozzle:

-

1

-

Plugging nozzle:

-

1

-

Dimension:

-

1540*1190*2000mm

Quick Details

-

Machinery Capacity:

-

5-20bpm

-

Packaging Material:

-

Plastic, Glass, Wood

-

Filling Material:

-

Veterinary, Gel, Dental Composite

-

Filling Accuracy:

-

≥99%

-

Applicable Industries:

-

Veterinary, Cosmetics, Medical

-

Place of Origin:

-

China

-

Weight:

-

860 KG, 860kg

-

Voltage:

-

220V50Hz

-

Motor Power:

-

4.2KW

-

Filling speed:

-

5-20BPM

-

Filling accuracy:

-

±1%-1.5%

-

Vacuum pumping rate:

-

80m³/hour

-

Filling volume:

-

1ml

-

Filling nozzle:

-

1

-

Plugging nozzle:

-

1

-

Dimension:

-

1540*1190*2000mm

PRODUCT DESCRIPTION

filling dial row by row from the slide. The dial rotates intermittently and feeds at a time. Insert a syringe into the dial wheel

and turn it to the corresponding work station.

Syringe filling: the syringe is brought to the filling station by the dial, a single filling needle is inserted into the syringe and rises while filling, and the syringe is sealed at the same time for vacuum during filling. The filling pump uses a special gel

ceramic pump Filling.

Vacuum stoppering of the syringe: the filled syringe is rotated by the dial to the stoppering station. The rubber stopper is

arranged by the oscillator and sent to the top of the syringe through the stopper track. A stopper rod first takes the rubber

stopper on the stopper rod On the upper side, the stopper rod is integrated with a vacuum body, and at the same time, the syringe is pressed down to seal and vacuum, and then the stopper rod is added to the liquid level of the syringe.

The finished product comes out: the finished syringe after filling and stoppering can be collected manually after being suspended and slipped out by a chute

and turn it to the corresponding work station.

Syringe filling: the syringe is brought to the filling station by the dial, a single filling needle is inserted into the syringe and rises while filling, and the syringe is sealed at the same time for vacuum during filling. The filling pump uses a special gel

ceramic pump Filling.

Vacuum stoppering of the syringe: the filled syringe is rotated by the dial to the stoppering station. The rubber stopper is

arranged by the oscillator and sent to the top of the syringe through the stopper track. A stopper rod first takes the rubber

stopper on the stopper rod On the upper side, the stopper rod is integrated with a vacuum body, and at the same time, the syringe is pressed down to seal and vacuum, and then the stopper rod is added to the liquid level of the syringe.

The finished product comes out: the finished syringe after filling and stoppering can be collected manually after being suspended and slipped out by a chute

PRODUCT PARAMETER

|

Filling Volume

|

1~20ml

|

|

Capacity

|

200-1200bph

|

|

Filling Head

|

1

|

|

Capping head

|

1

|

|

Accuracy

|

±1%-1.5% Gel rotary valve plunger pump (the greater

the viscosity, the greater the error)

|

|

Vacuum pumping rate

|

80m³/hour, close to

|

|

Machine size

|

1250x950x1800(mm)

|

PRODUCT APPLICATION

DETAILED IMAGES

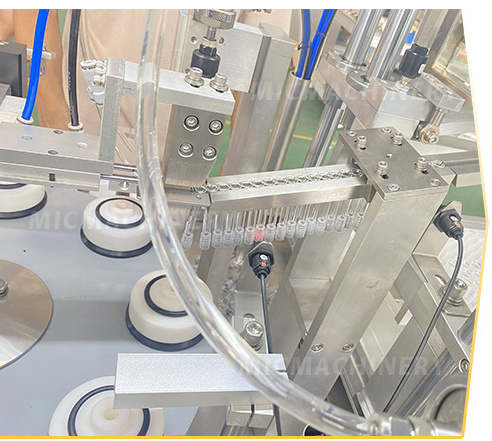

Syringe tube loading guider

Syringe sort of vibrating plate will sort of the syringe tubes and send to the loading guider one by one, loading guider will send syringe tub into turn table

Working Station

Included the syringe loading guider.Servo motor control filling Automatic plugging and vacuum.Output finish product guider

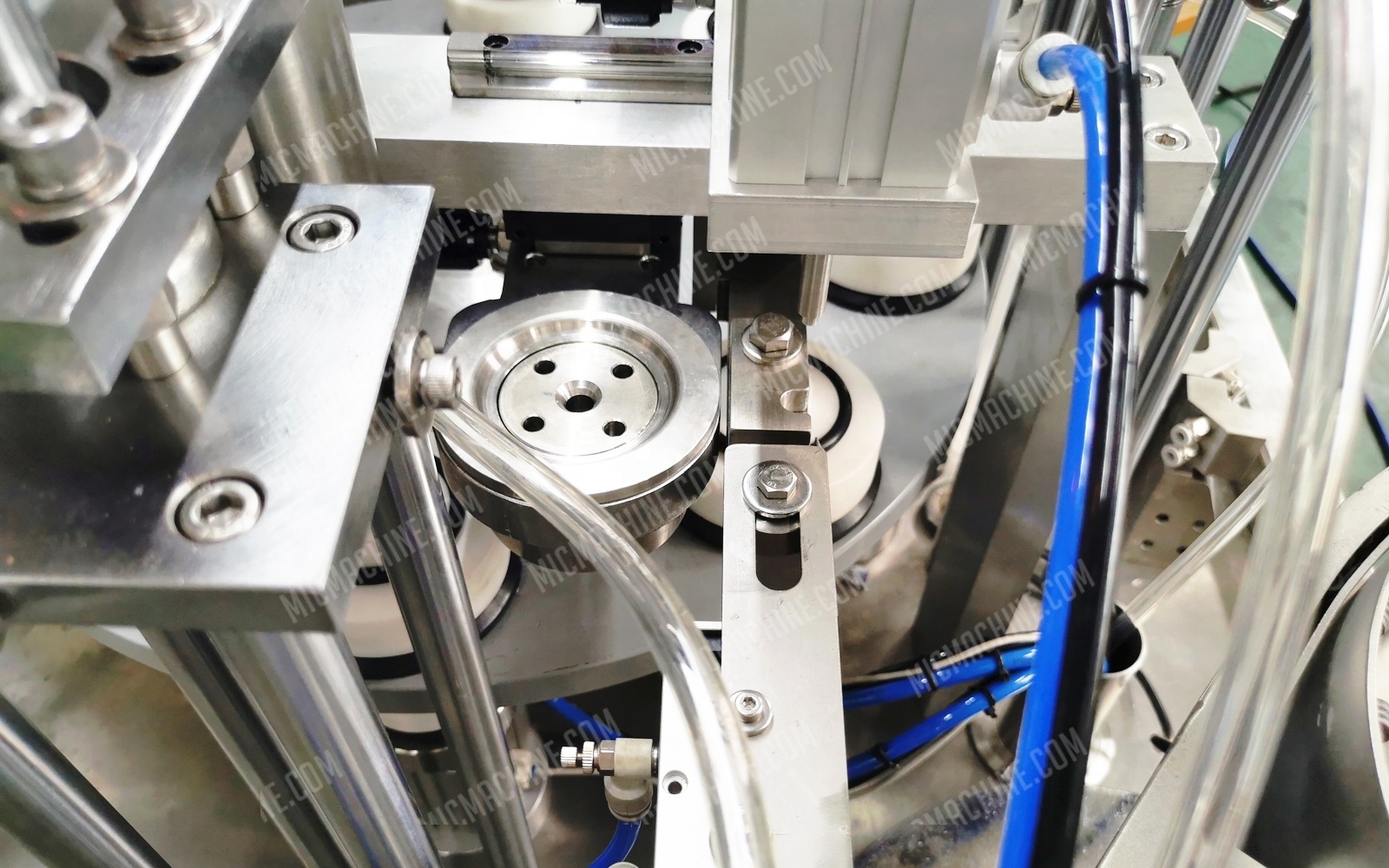

Vacuum plugging station

Vibrating plate will sort of the rubber plug automatically.And send plug into plugging station, Then plugging insert hear will insert it into syringe and vacuum at same time

Arrange and Feeding Caps

.

Using the vibrating disk to sort the caps automatically.Then the arranged caps will drop into capping station

Vacuum plugging

Sorting out the plugs from vibrating tray,through the loadingplug tunnel,sucking the plug on the plugging station, then vacuum pressed plugging

COMPANY INTRODUCTION

FAQ

Hot Searches