Quality stainless steel

Contact parts of machine are completely made of food grade stainless steel 304/316L, meeting the standard of GMP.

- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

1000 KG

-

Product Type:

-

mixer machinery for hot melt glue

-

Additional Capabilities:

-

stainless steel mixer

-

Place of Origin:

-

China

-

Brand Name:

-

BLS

-

Voltage:

-

110-480V, 50/60hz

-

Dimension(L*W*H):

-

Referring

-

Power (kW):

-

25 kW

-

Warranty:

-

12 months

-

volume:

-

100-5000L

-

Mixers types:

-

frame, scraper, homogenizer etc

-

Sealing mechanism:

-

mechanical sealing avaible

-

Heating methods:

-

steam, electric heating and heat guiding oil

-

Function:

-

glue melter

-

Usage:

-

hot melt glue machine

-

Type:

-

industrial hot melt glue machine

-

Product name:

-

industrial steel mixer machinery for hot melt glue

-

Application1:

-

steel mixer machinery for hot melt glue

Quick Details

-

Barrel Volume (L):

-

8000 L

-

Max. Loading Volume (L):

-

8000 L

-

Range of Spindle Speed(r.p.m):

-

20 - 3000

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

1000 KG

-

Product Type:

-

mixer machinery for hot melt glue

-

Additional Capabilities:

-

stainless steel mixer

-

Place of Origin:

-

China

-

Brand Name:

-

BLS

-

Voltage:

-

110-480V, 50/60hz

-

Dimension(L*W*H):

-

Referring

-

Power (kW):

-

25 kW

-

Warranty:

-

12 months

-

volume:

-

100-5000L

-

Mixers types:

-

frame, scraper, homogenizer etc

-

Sealing mechanism:

-

mechanical sealing avaible

-

Heating methods:

-

steam, electric heating and heat guiding oil

-

Function:

-

glue melter

-

Usage:

-

hot melt glue machine

-

Type:

-

industrial hot melt glue machine

-

Product name:

-

industrial steel mixer machinery for hot melt glue

-

Application1:

-

steel mixer machinery for hot melt glue

Industrial Steel Bitumen emulsion high speed shearing emulsifying tank, industrial blending coffee with flavour machinery

It is widely used in food, cosmetics, dyestuff, and so on to complete the heating, stirring, polymerization, sterilization and other process, the use of high temperature, It is a prerequisite for participating in the full mixing of the reactants. For physical changes such as heating, cooling, and liquid extraction and gas absorption, a stirrer is required to achieve good results, and the reactor can be designed according to the customer's requirements.

Reference parameters :

1. Tank body: stainless steel (SUS304, SUS316L) material, the inner surface of the mirror polishing,

2. Can be online CIP cleaning, SIP sterilization, in line with health norms

3. Mixing device: optional box-type, anchor type, such as pulp

4. Heating and cooling: steam heating or electric heating can be used

5. Stirring Seal: the use of pressure sanitary mechanical seal device to maintain the working pressure inside the tank and to prevent leakage of materials within the tank.

6. Support type According to the operational requirements of the use of hanging ear-type or floor leg type.

|

Volume (L)

|

Dimension D*h (mm*mm)

|

Height (mm)

|

In/Outlet diameter (mm)

|

Heat preservation layer

|

|

1000

|

1060*1220

|

2550

|

51

|

60

|

|

1500

|

1160*1500

|

2850

|

51

|

60

|

|

2000

|

1340*1500

|

2900

|

51

|

60

|

|

3000

|

1410*2000

|

3400

|

51

|

60

|

|

4000

|

1620*2000

|

3450

|

51

|

60

|

|

5000

|

1810*2000

|

3500

|

51

|

60

|

|

6000

|

1930*2000

|

3550

|

51

|

60

|

|

7000

|

1930*2440

|

4000

|

51

|

60

|

|

8000

|

2060*2440

|

4000

|

51

|

60

|

|

9000

|

2180*2440

|

4050

|

51

|

60

|

|

10000

|

2300*2440

|

4050

|

51

|

60

|

|

12000

|

2270*3000

|

4600

|

51

|

60

|

|

15000

|

2530*3000

|

4700

|

51

|

60

|

|

20000

|

2640*3660

|

5400

|

51

|

60

|

Motor device

1. Pure copper motor: low noise, stable dynamic, sustainable work.

2. Dust proof engine base: inside stainless steel bearing, with dust cover to avoid dust and grease dirt into tank.

Flat cover /Shell cover

Inlet port and outlet port

1. Available port connection: Clamp, Thread Butt weld, Flange etc.

2. Flange process arc transition smooth, easy to clean no dead ends, beautiful appearance.

Full Stainless steel small oil cup

be provided for filling Conduction oil, easy use and difficult outflow.

Drain valve

Ball valve, can get rid of extra water inside interlining

Discharge port

direct discharge port on the bottom connected with clamped discharge valve

SS agitator

1. Rotation speed can be constant speed, also can be equipped with VFD according to real work condition.

2. Agitator can be frame mixer, paddle, scattered disk, scraper, ribbon etc.

Temperature control

Using thermocouple to measure the temperature and connected with temperature controller to control the temperature, and also can adjust the temperature of material in tank .

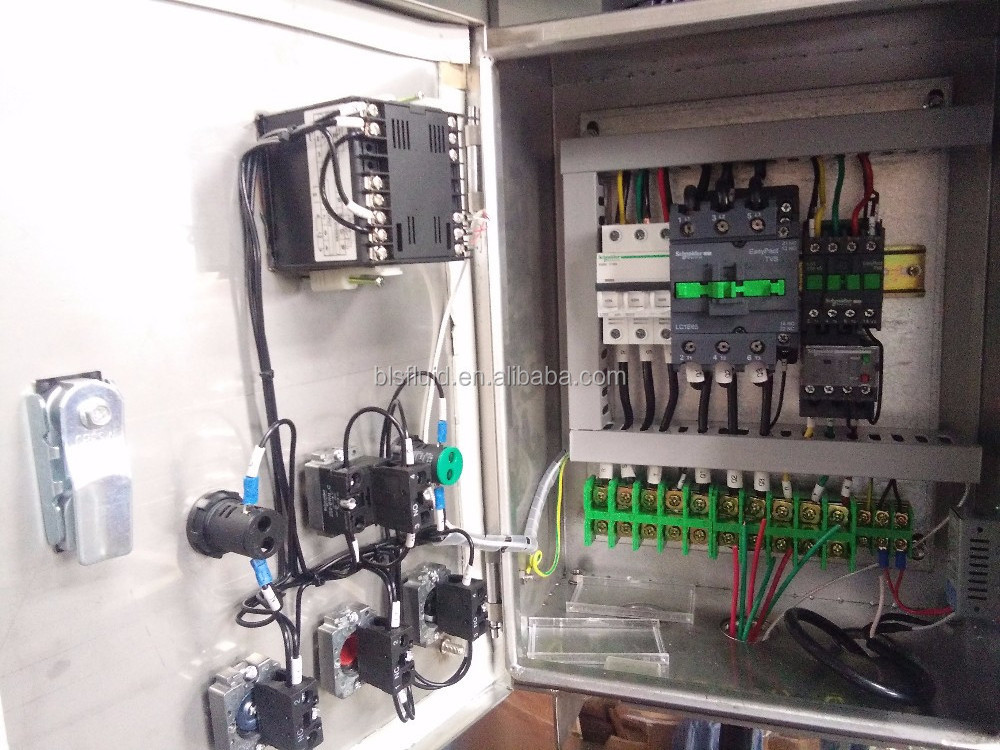

Electric control box:

1. intelligent temperature controller, SS304 box

2. PT100 thermal resistance

3. Germany Schneider Electric Components

Sight glass:

tempered glass material, threaded connection form.

Heating device : Electric heating

1. the interlayer is provided with electric heating rods.

2. heating of the liquid indirect through heat transfer of a water bath;

thermometer:

show the inside tank feeding material temperature

Zhejiang L&B Fluid Equipment co., Ltd

a modern enterprise which combine the ability of design, development, manufacturing, engineering, installation, technical services, has special technology to design and exploit by CAD software and computer and is a outstanding leader among valve fields.

We have advanced CNC lathes imported from Japan.We can manufacture the valves and fitting according to ISO, DIN, IDF, SMS, 3A, while we can produce the products per as the requirement from the clients(non-standard).

We are specialized in producing different kinds of valves, pipe fitting, tubes, manhole covers, pumps, tanks etc for many years. We can design the products according to your special request. OEM is welcome too.

Q1. What is your terms of packing?

A: Generally, we pack our goods in plywood case or carton package for small parts.

If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q6.Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

|

Please contact our After-sales service department in time within 30days after you received the cargo.

|

|

|

|

Tel: 86-577-86821328 Time: 9:00 a.m.- 6:00 p.m. (Beijing time)

|

|

|

|

Process

|

Please provide the copy of Sales Contract and describe the problems appeared.

|

|

|

Problems confrimation:

|

|

|

|

Slight problem:

|

Please send the proof to our After-Sales Department, we will reply within two days.

|

|

|

Serious problem:

|

|

|

|

a

|

We will dispatch our Quality and Problems Appraisers to make a confirmation.

|

|

|

b

|

Have a negotiation of the compensation and sign agreements

|

|

|

c

|

Our After-Sales Department will perform the duties as the agreements

|

|