- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

100-230 mm

-

Color:

-

Black ,red, blue

-

Feature:

-

sharp,long life, durable

-

Packing:

-

inner box+carton

-

Certificate:

-

ISO9001:2008

-

Product name:

-

Flap discs

-

Sample:

-

Free Provided

-

Max.rpm:

-

8400-13300

-

Grit:

-

40#~120#

-

Application:

-

Polishing grinding

-

Certification:

-

ISO9001

Quick Details

-

Type:

-

Abrasive Disc

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

OEM

-

Model Number:

-

100-230 mm

-

Color:

-

Black ,red, blue

-

Feature:

-

sharp,long life, durable

-

Packing:

-

inner box+carton

-

Certificate:

-

ISO9001:2008

-

Product name:

-

Flap discs

-

Sample:

-

Free Provided

-

Max.rpm:

-

8400-13300

-

Grit:

-

40#~120#

-

Application:

-

Polishing grinding

-

Certification:

-

ISO9001

Product Description

FLAP DISCS

Flap discs are designed with abrasive cloth strips glued on to a rigid backing in a fan arrangement. Flap discs can replace in many operations, both grinding wheels and fibre discs. It is possible by using flap discs to cut and finish in one operation. The unique construction allows for new grain to be constantly in contact with the surface, as the flaps continually wear out. The life of a flap disc can be 20 times that of a fibre disc, resulting in a major cost reduction in both labor and material costs.

A new heavy-duty product is available which gives high performance for weld removal on corners, flame cut edges, heavy deburring and cleaning of spot welds.When removing the left over metal from the joint area, the motion of the grinder is the same as when using the rough grindingdisc.

Press the face of the disc into the work and work evenly around the tubing until it appears flush with the head tube shell.

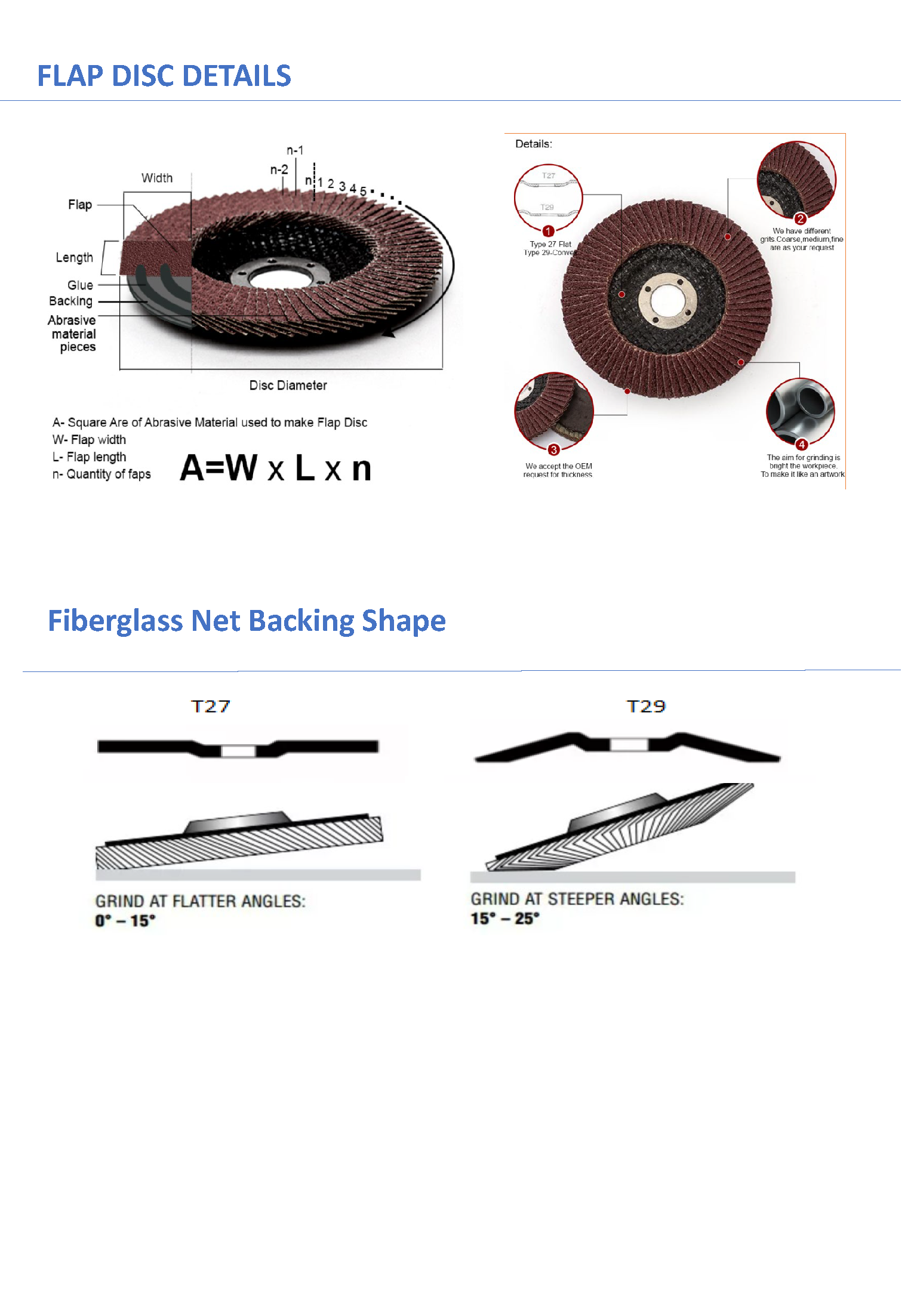

Shape:

Flap discs are broken down into flat and angle face. Following grinding wheel terminology flat discs are type 27 while angle discs are type 29. Typical angle faced flap wheels are about 10°. Angle faced discs are more aggressive and are more suited to stock removal while flat faced discs are better on flat surfaces and will produce a more consistent finish.

Flap discs are broken down into flat and angle face. Following grinding wheel terminology flat discs are type 27 while angle discs are type 29. Typical angle faced flap wheels are about 10°. Angle faced discs are more aggressive and are more suited to stock removal while flat faced discs are better on flat surfaces and will produce a more consistent finish.

Backing Plate:

Flap discs come with aluminum, fiberglass or plastic backing plates. Fiberglass is the most common. Aluminum is sometimes chosen due to no potential fiberglass dust hazards. Plastic backing is becoming more popular with some manufacturers suggesting that the plastic backing can be trimmed to increase working life.

Flap discs come with aluminum, fiberglass or plastic backing plates. Fiberglass is the most common. Aluminum is sometimes chosen due to no potential fiberglass dust hazards. Plastic backing is becoming more popular with some manufacturers suggesting that the plastic backing can be trimmed to increase working life.

|

Size

|

Backing Diameter

|

Hole Diameter

|

Grain Size

|

Max RPM

|

Pcs/CTN

|

G.W.(kgs)

|

N.W.(kgs)

|

Ctn Size(cm)

|

|

4” 100mm |

75/90mm |

5/8” 16mm |

40#

|

15300

|

200

|

14

|

13

|

53*21*23

|

|

|

|

|

60-80#

|

15300

|

200

|

12

|

11

|

53*21*23

|

|

|

|

|

120-400#

|

15300

|

200

|

10

|

9

|

53*21*23

|

|

4.5”

115mm |

105mm |

7/8” 22mm |

40#

|

13300

|

200

|

18

|

17

|

59*24*24

|

|

|

|

|

60-80#

|

13300

|

200

|

17

|

16

|

59*24*24

|

|

|

|

|

120-400#

|

13300

|

200

|

15

|

14

|

59*24*24

|

|

5” 125mm |

115mm |

7/8” 22mm |

40#

|

12200

|

200

|

21

|

20

|

64*26*24

|

|

|

|

|

60-80#

|

12200

|

200

|

20

|

19

|

64*26*24

|

|

|

|

|

120-400#

|

12200

|

200

|

18

|

17

|

64*26*24

|

|

6” 150mm |

140mm |

7/8” 22mm |

40#

|

10200

|

150

|

21

|

20

|

48*31*30

|

|

|

|

|

60-80#

|

10200

|

150

|

20

|

19

|

48*31*30

|

|

|

|

|

120-400#

|

10200

|

150

|

18

|

17

|

48*31*30

|

|

7” 180mm |

170mm |

7/8” 22mm |

40#

|

8500

|

100

|

25

|

24

|

37*37*30

|

|

|

|

|

60-80#

|

8500

|

100

|

22

|

21

|

37*37*30

|

|

|

|

|

120-400#

|

8500

|

100

|

20

|

19

|

37*37*30

|

Advantages

1.Bonded to extremely strong but durable fibreglass or plastic backing

2.Fast ,aggressive action for high pressure grinding,high efficiency

3.Blending and finishing all in one operation and will reduce process time,lower total grinding cost

4.Maximum contact with work surface with out loading

5.Consistent grinding and finishing performance

6.Excellent performance and efficiencies on stainless and carbon steel application

7.Reduce vibration and noise compared to depressed denter grinding discs. .

2.Fast ,aggressive action for high pressure grinding,high efficiency

3.Blending and finishing all in one operation and will reduce process time,lower total grinding cost

4.Maximum contact with work surface with out loading

5.Consistent grinding and finishing performance

6.Excellent performance and efficiencies on stainless and carbon steel application

7.Reduce vibration and noise compared to depressed denter grinding discs. .

Customer Photos

Certifications

Product packaging

Why Choose Us

About Biz-Harmony

WHO IS BIZ-HARMONY?

ARE WE A RELIABLE SUPPLIER?

+ Our clients are all over the world. We are proud to find that our products are being used in different countries.

+ Product quality is always our first priority, and professional service makes us outstanding from other suppliers. We believe that there is no best product or service in the world, however, we are always trying to provide a better one.

+ Product quality is always our first priority, and professional service makes us outstanding from other suppliers. We believe that there is no best product or service in the world, however, we are always trying to provide a better one.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME!

+ Welcome to visit our production line.

+ Welcome to talk with our engineers.

Contact Us

Hot Searches