- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Weight (KG):

-

5

-

Core Components:

-

wire mesh

-

Place of Origin:

-

China

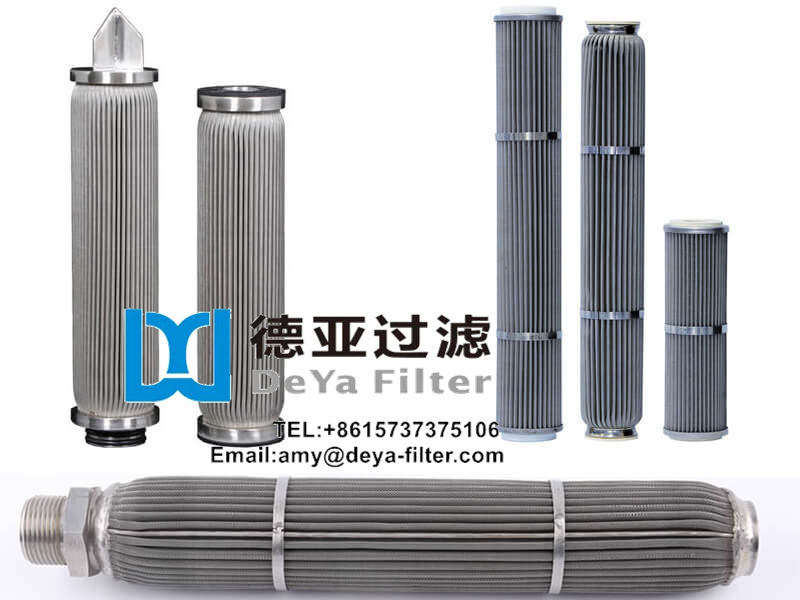

Pleated stainless steel wire mesh filter cartridge

What is the stainless steel filter cartridge

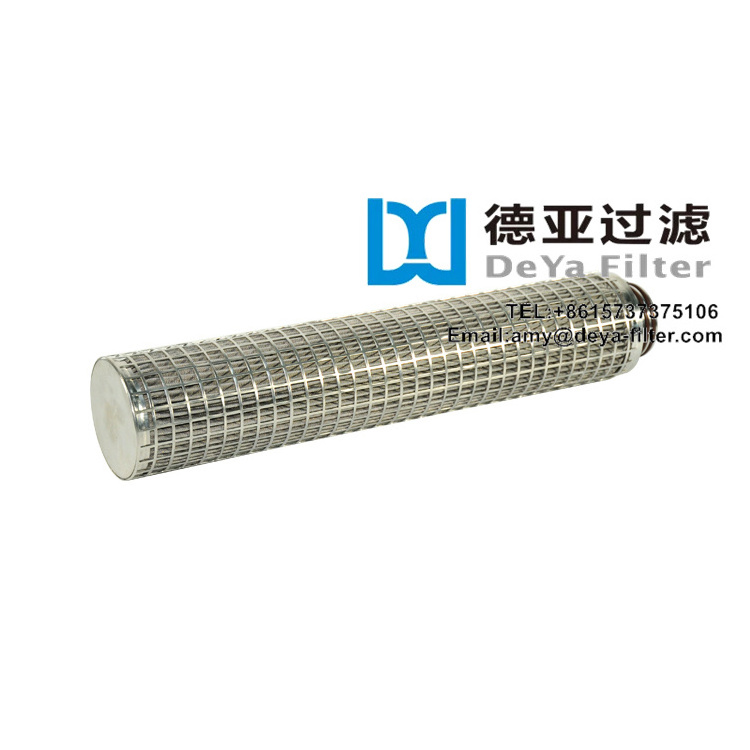

Stainless steel filter cartridge is the filter element made of stainless steel filter media and hardware, and which is in the shape of tube or cylinder working as cartridge.

-

MaterialStainless steel, filter paper, stainless steel wire cloth .

-

Material typeSS304, SS304L, SS316, SS316L.

-

TypeStainless steel filter, wire-wound filter element, pleated filter element.

-

Filter precision200–2000 μm.

-

Filter efficiency≥ 95%.

-

Working pressure0.1–1.6 MPa.

-

Working temperature≤ 95 °C.

-

Connection typeMetal flange.

-

ShapeCylinder, pleated, disc, basket, panel, conical, wedge, leaf, candle, belt, any outline shape available according to customer's requirement.

-

ProcessSintered, knitted wire mesh, wire cloth, woven wire mesh, expanded, punched, wire-wound, etc.

-

ColorGrey, blue, red, etc.

-

PackageStandard pallet with waterproof film, or according to your requirement.

1. Protection Layer: Protection of the filter layer against physical influences

2. Filter Layer: Selected according to the pore size

3. Protection Layer: Protects the filtration layer from possible deformation under high pressure

4. Support layer: Makes wire cloth laminate stable and improves the welding characteristics

5. Support layer 90 : Makes wire cloth laminate stable and improves the welding characteristics

6. Drainage layer : improves the quantity of the filter capacity

Connectors of Pleated stainless steel wire mesh filter cartridge

Advantages of Pleated stainless steel wire mesh filter cartridge

Stainless steel filter cartridges are more suitable to high temperature and high pressure working conditions than most of the non-metallic filter cartridges.

And they are applicable for various cleaning methods which are often not acceptable for non-metallic filter, such as high pressure water washing, chemical bath, ultrasonic cleaning, heating and even incineration.

Therefore the stainless steel filter cartridges are the best choice for automatic filter with backwashing or backflushing.

Quality control--bubble point testing

Bubble point testing is a method used to test the integrity of woven wire mesh by applying pressure to create bubbles and identify the pore size of the mesh. This allows you to ensure the mesh can reach a desirable throughput and accuracy level.

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral cartons. If you have legally registered

patent, we can pack the goods in your branded boxes after getting your authoriza-

tion letters.

Q2. What is your terms of payment?

A: 100%TT or T/T 50% as deposit, and 50% before delivery For long term business relations, we have more advantage terms for

payment.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, within a week

Q5. Can you produce according to the samples or drawings?

A: Yes, we can produce by your samples or technical drawings. We can build the

molds and fixtures.

Q5-1: How about oil filter tooling Charge?

A: Tooling charge only charge once when first order, all future orders would not

charge again even tooling repair or under maintence.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have

to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit;

2. We respect every customer as our friend and we sincerely do business and make

friends with them, no matter where they come from.