- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TB

-

Model Number:

-

Copper Coated Steel Fiber

-

Tensile strength:

-

>1100MPA

-

Shape:

-

Hooked ends, direct bar

-

Length:

-

30-60 mm customized

-

Advantages:

-

Excellent Tensile, High Tenacity,Cost Saving

-

Certificate:

-

ISO 9001

-

Brand:

-

Hongda

-

Brass Steel Fiber:

-

Copper-Plated Steel Fiber

-

Microfiber steel fiber:

-

Brass Coated Steel Fiber

-

Keyword:

-

Copper Coated Steel Fiber

Quick Details

-

Project Solution Capability:

-

graphic design, Cross Categories Consolidation

-

Application:

-

Hotel

-

Design Style:

-

Midcentury

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TB

-

Model Number:

-

Copper Coated Steel Fiber

-

Tensile strength:

-

>1100MPA

-

Shape:

-

Hooked ends, direct bar

-

Length:

-

30-60 mm customized

-

Advantages:

-

Excellent Tensile, High Tenacity,Cost Saving

-

Certificate:

-

ISO 9001

-

Brand:

-

Hongda

-

Brass Steel Fiber:

-

Copper-Plated Steel Fiber

-

Microfiber steel fiber:

-

Brass Coated Steel Fiber

-

Keyword:

-

Copper Coated Steel Fiber

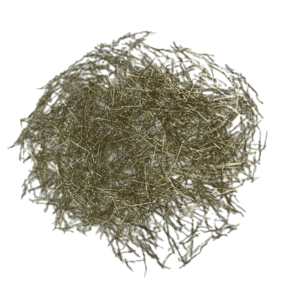

We offer Steel Fibers made from prime quality hard-drawn steel wire to ensure high tensile strength and close tolerances. The wire is deformed with hooked ends and cut to lengths, for reinforcement of concrete, mortar and other composite materials. The performance of Steel Fibers depends on both the dosage (kg/m3) and the fiber parameters (tensile strengths, length, diameter and anchorage). A key factor for quality of Steel Fibers is the relationship between the length and the diameter of the fibers - the higher the l/d ratio, the better the performance.

Steel Fibre Reinforced Concrete (SFRC) gives concrete its high performance because the steel fibers are homogeneously distributed. Thus, contributing to considerable increase in load-bearing capacity, high durability and high impact resistance, and all this ensures a longer lifetime with low maintenance cost. Apart from a wide usage, the Steel Fibers are also used as sprayed concrete (shotcreting), slope stabilization, pre-cast concrete production tunnel and mining shafts and underwater concrete reinforcement. Steel Fibres are also popularly used in manufacturing precast walls, overlays, manhole covers, piles & pillars.

SFRC Applications

1. For Flooring

Industrial floors

Joint-less floors

Floors-on-piles

Lightly loaded floors

Liquid tight floors & composite metal decking

2. For Hard Standing & Heavy Duty

Parking lots

Playgrounds

Airport runways

Taxiways

Maintenance hangers

Access roads & workshops

Ports& Containers for port pavements

Container terminals

Bulk storage areas access roads

For army tank movement

3. Other Applications

Foundations

Traditional cellar and basement walls

Compression layers

Shapes of Steel Fibres:

They are available in various shapes and sizes

Hooked End Steel Fibers

Crimped Round and Flat Steel Fibers

Flat End Steel Fibers

Suitable For:

Shotcreting of tunnels

Slope Stabilizations

Mine Roof Support

Pre Cast for Tunnel Linings

Foundation Slabs

Roads

Bridges

Runwas

Taxiways

Factory Flooring

Pre Cast walls

Concrete Pipes

Manhole Covers

Advantages:

Result in more homogeneous mix in concrete

Flexural strain capacity is enhanced

Add ductility to concrete

Control cracks

Joint stability

Narrow joint width

Shear load transfer

Fatigue and impact resistance

Post crack ductility

Reduce material consumption and save cost - on average a Steel Fibre slab will overall cost between 10-15% less than an equivalent mesh slab.

Longer service life

Quick & Easy Application: Steel Fibres can be added at the concrete plant or at the job site directly in to the back of the truck mixer. You can then pour pre-reinforced concrete.

|

Types |

Diameter(mm) |

Length(mm) |

Tensile Strength(Map) |

|

Hooked ends steel fiber |

0.5-1.0 |

30-60 |

>1100 |

|

Copper coated steel fiber |

0.5-1.0 |

30-60 |

>1100 |

|

Glued steel fiber |

0.5-1.0 |

30-60 |

>1100 |

|

Wavy steel fiber |

0.5-1.0 |

30-60 |

>1100 |

|

Milling steel fiber |

/ |

30-60 |

>1500 |

|

Or according to customer ’ s requirement |

|||