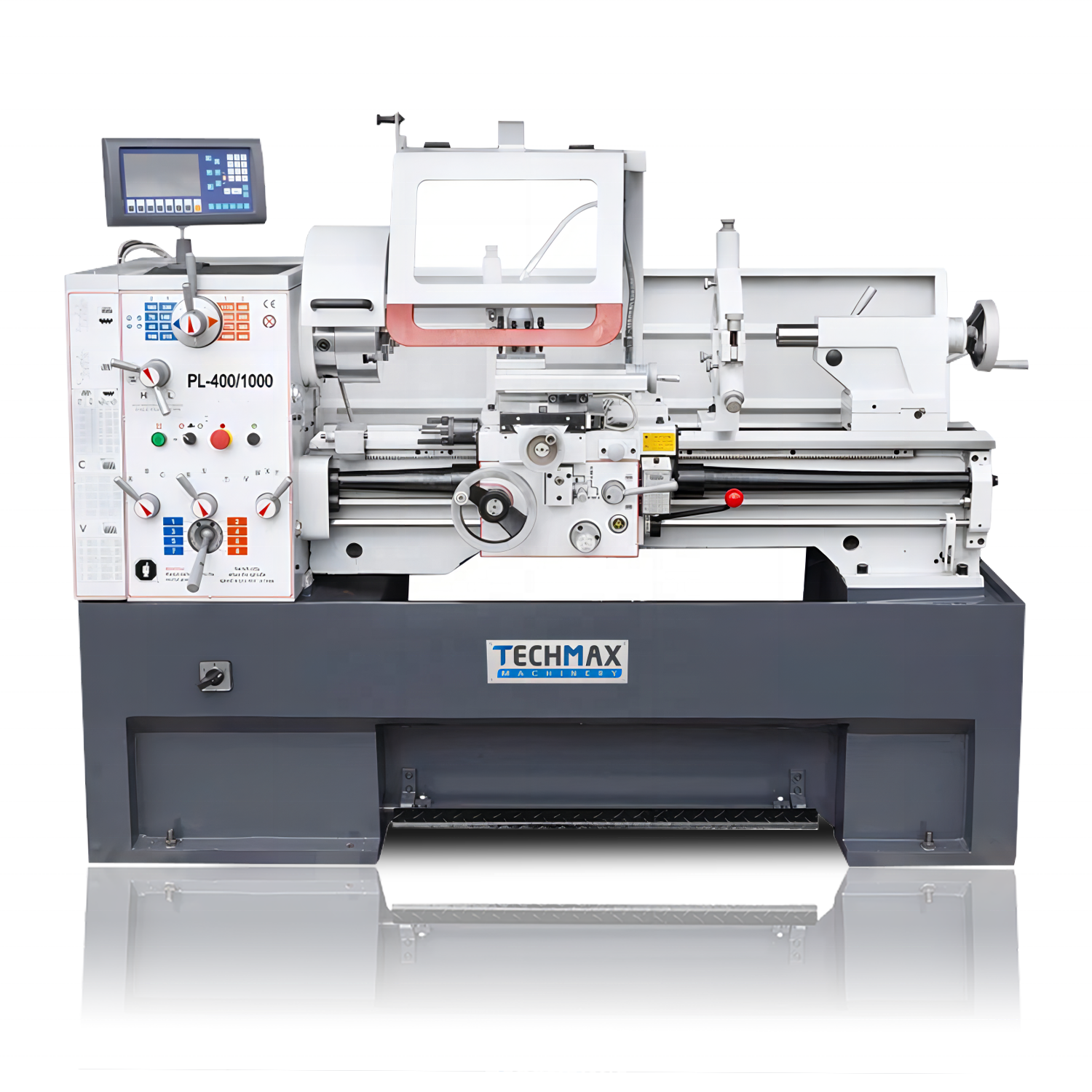

- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

45 - 1800 r.p.m

-

Width of bed (mm):

-

250

-

Max. Turned Length (mm):

-

1450 mm

-

Spindle Motor Power(kW):

-

3.3/2.2

-

Year:

-

custom made

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Techmax

-

Model Number:

-

PL-400

-

Voltage:

-

As per the client's request

-

Dimension(L*W*H):

-

2560*900*1640mm

-

Weight (KG):

-

1750 KG

-

Marketing Type:

-

Hot Product

-

Center height:

-

205mm

-

Swing over bed:

-

410mm

-

Spindle nose fixture:

-

D1-6

-

Longitudinal feed:

-

(17) 0.05-1.7

-

Cross feed:

-

(17) 0.025-0.85

-

Inch thread:

-

2-72 (45)

-

Metric thread:

-

0.1-14 (39)

-

Module thread:

-

0.3-3.5 (18)

Quick Details

-

Max. Length of Workpiece (mm):

-

1500

-

Machining Capacity:

-

Medium Duty

-

Spindle Bore(mm):

-

52

-

Range of Spindle Speed(r.p.m):

-

45 - 1800 r.p.m

-

Width of bed (mm):

-

250

-

Max. Turned Length (mm):

-

1450 mm

-

Spindle Motor Power(kW):

-

3.3/2.2

-

Year:

-

custom made

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Techmax

-

Model Number:

-

PL-400

-

Voltage:

-

As per the client's request

-

Dimension(L*W*H):

-

2560*900*1640mm

-

Weight (KG):

-

1750 KG

-

Marketing Type:

-

Hot Product

-

Center height:

-

205mm

-

Swing over bed:

-

410mm

-

Spindle nose fixture:

-

D1-6

-

Longitudinal feed:

-

(17) 0.05-1.7

-

Cross feed:

-

(17) 0.025-0.85

-

Inch thread:

-

2-72 (45)

-

Metric thread:

-

0.1-14 (39)

-

Module thread:

-

0.3-3.5 (18)

❶

Inductive hardened, polished grey cast-iron machine bed

❷

Electro-mechanical foot brake reduces downtime significantly

❸

State-of-the-art main spindle bearing with high-quality angular ball bearings

❹ Modern bearing of main spindle with angular ball bearing in precision construction

❹ Modern bearing of main spindle with angular ball bearing in precision construction

❺

Easy, smooth and precisely adjustable speed and feed settings

❻

Hardened, polished gears and shafts, also in feed gear unit

❼ Centrally located, logical switches for feeds and threads with leadscrew and feed rod

❼ Centrally located, logical switches for feeds and threads with leadscrew and feed rod

❽

Adjustable tailstock for taper turning, handwheel feature adjustable scale (0,02 mm)

❾

The removeable bridge allows machining of workpieces with a big diameter

|

Specification

|

Unit

|

PL-400

|

PL-400 Vario

|

|

Distance between centers

|

mm

|

1000/1500

|

1000/1500

|

|

Center height

|

mm

|

205

|

205

|

|

Swing over bed

|

mm

|

Φ400

|

Φ400

|

|

Swing over cross slide

|

mm

|

Φ255

|

Φ255

|

|

Swing over gap

|

mm

|

Φ580

|

Φ580

|

|

Bed width

|

mm

|

250

|

250

|

|

Spindle bore

|

mm

|

Φ52

|

Φ52

|

|

Spindle nose fixture

|

-

|

D1-6

|

D1-6

|

|

Spindle speed

|

rpm

|

(16) 45-1800

|

(stepless) 30-550 / 550-3000

|

|

Longitudinal feed

|

mm/rev

|

(17) 0.05-1.7

|

(17) 0.05-1.7

|

|

Cross feed

|

mm/rev

|

(17) 0.025-0.85

|

(17) 0.025-0.85

|

|

Inch thread

|

TPI

|

2-72 (45)

|

2-72 (45)

|

|

Metric thread

|

mm

|

0.1-14 (39)

|

0.1-14 (39)

|

|

Module thread

|

MP

|

0.3-3.5 (18)

|

0.3-3.5 (18)

|

|

Diametral thread

|

DP

|

8-44 (21)

|

8-44 (21)

|

|

Lead screw thread

|

TPI

|

4

|

4

|

|

Top slide travel

|

mm

|

140

|

140

|

|

Cross slide travel

|

mm

|

210

|

210

|

|

Tool section size

|

mm

|

20×20

|

20×20

|

|

Tailstock sleeve diameter

|

mm

|

Φ50

|

Φ50

|

|

Tailstock sleeve travel

|

mm

|

120

|

120

|

|

Tailstock sleeve taper

|

-

|

MT4

|

MT4

|

|

Spindle drive motor

|

kw

|

3.3/2.2

|

3.3/2.2

|

|

Coolant pump motor

|

kw

|

0.09

|

0.09

|

|

Packing size (L×W×H)

|

cm

|

206/256×90×164

|

206/256×90×164

|

|

Weight approx.

|

kg

|

1500/ 1750

|

1555/1755

|

|

Standard Configuration

|

Optional Configuration

|

|

❶

3-jaw chuck

❷ 4-jaw chuck ❸ Face plate ❹ Steady rest ❺ Follow rest ❻ Dead center ❼ Reducing sleeve ❽ Foot brake ❾ Oil gun ❿ Working light ⓫ Cooling system

⓬

Tool-box & tools

⓭ Operation manual |

❶

2 axes DRO

❷ Quick change tool post ❸ Taper turning accachment ❹ Chasing dial indicator ❺ Live Center |

1. How can I choose the most suitable machines ?

Re: Please tell us your specifications ,we can choose the best model for you , or you can choose the exact model . You can also send us the products drawing ,we will choose the most suitable machines for you.

2. What's your main products of your company?

Re: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Manual Lathe Machine,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on.

3. What kinds of inspection you will do for each machine?

Re: For each assembly procedure, there is geometric accuracy test. After assembly, spindle accuracy will be tested by dynamical balance testing instrument; 3 axes accuracy will be tested by Ball bar. And laser interferometer to inspect positioning and repositioning accuracy. Then the inspection team will make full test before delivery and test piece will be done on each machine. Each workpiece will be inspected by CMM, so each machine performance can be checked and kept in record.

4. Can you supply turn-key solution?

Re: Of course, we have professional team of technical service & after sale service department, who can give you the perfect solution and meet your processing requirement. Besides, we also cooperated with professional fixture company and support with us.

5. What is the warranty time of machine?

Re: We have 14 months warranty after delivery. Within the warranty period, if there is any problem not caused by wrong operation, we will supply you the replacing parts from free. Even beyond the period, we will still supply the replacing parts with cost price.

6. What is the delivery time, and what is the package?

Re: Normally the delivery time is about 45-60 days. All our machines are packed with the seaworthy wooden case/pallet, also applied with anti rust measures in advance. View drawing together if any parts disassembled.

2. What's your main products of your company?

Re: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Manual Lathe Machine,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on.

3. What kinds of inspection you will do for each machine?

Re: For each assembly procedure, there is geometric accuracy test. After assembly, spindle accuracy will be tested by dynamical balance testing instrument; 3 axes accuracy will be tested by Ball bar. And laser interferometer to inspect positioning and repositioning accuracy. Then the inspection team will make full test before delivery and test piece will be done on each machine. Each workpiece will be inspected by CMM, so each machine performance can be checked and kept in record.

4. Can you supply turn-key solution?

Re: Of course, we have professional team of technical service & after sale service department, who can give you the perfect solution and meet your processing requirement. Besides, we also cooperated with professional fixture company and support with us.

5. What is the warranty time of machine?

Re: We have 14 months warranty after delivery. Within the warranty period, if there is any problem not caused by wrong operation, we will supply you the replacing parts from free. Even beyond the period, we will still supply the replacing parts with cost price.

6. What is the delivery time, and what is the package?

Re: Normally the delivery time is about 45-60 days. All our machines are packed with the seaworthy wooden case/pallet, also applied with anti rust measures in advance. View drawing together if any parts disassembled.

Hot Searches