Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HighLeap

-

Copper Thickness:

-

1oz

-

Min. Hole Size:

-

0.2mm

-

Min. Line Width:

-

0.1mm

-

Min. Line Spacing:

-

0.1mm

-

Surface Finishing:

-

HASL/Lead free HASL

-

Board Size:

-

OEM

-

Application:

-

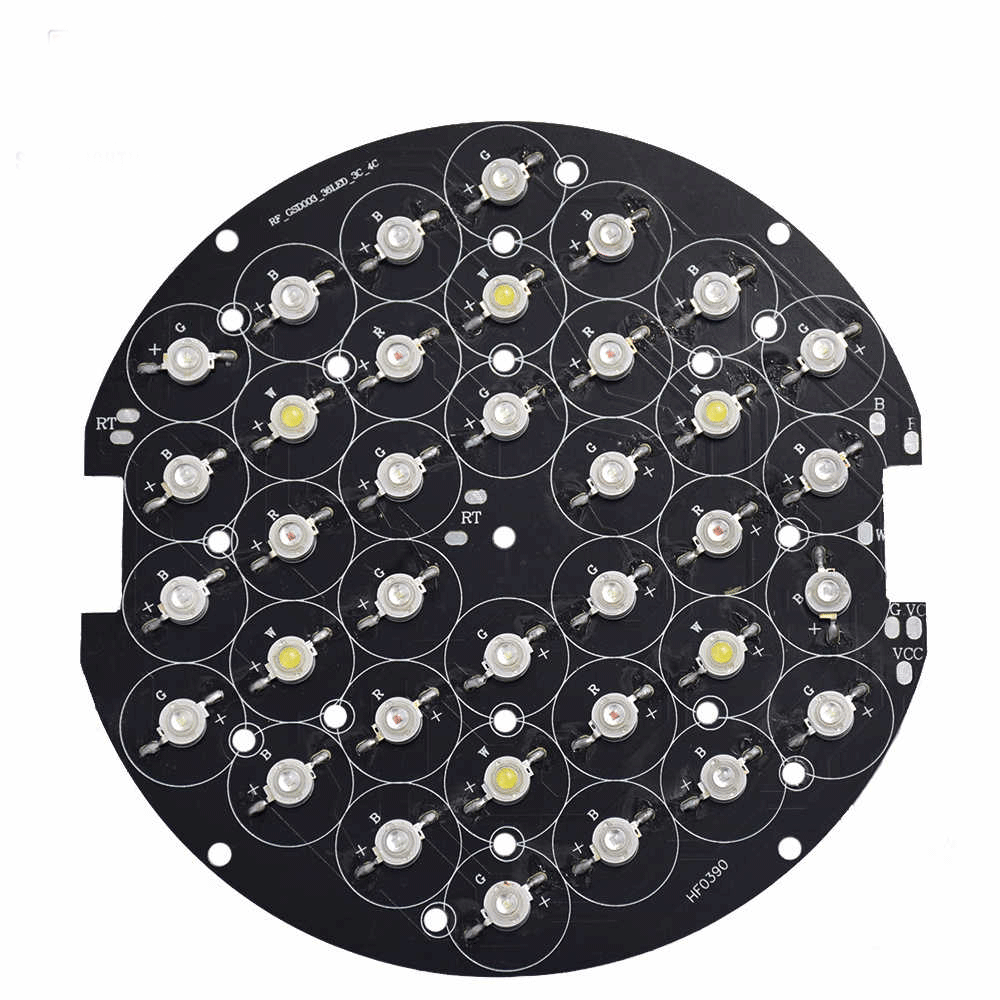

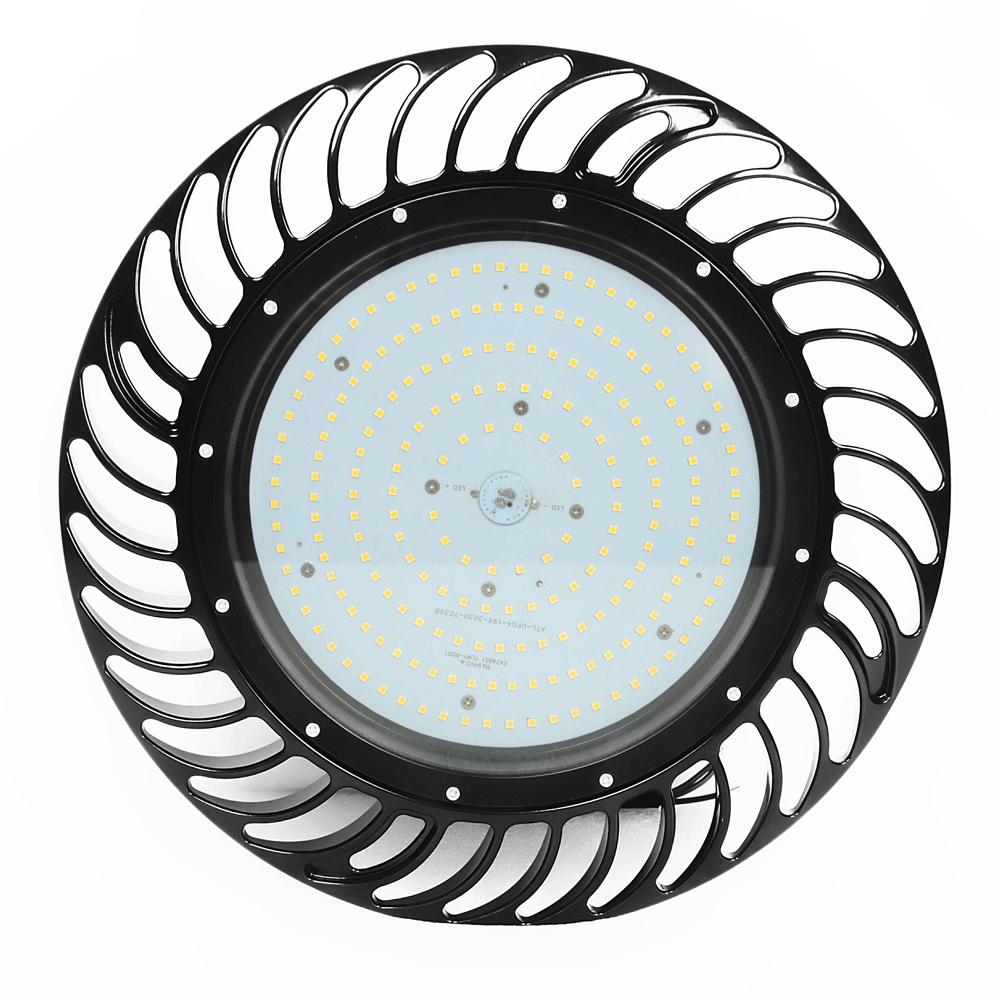

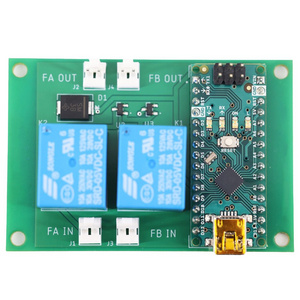

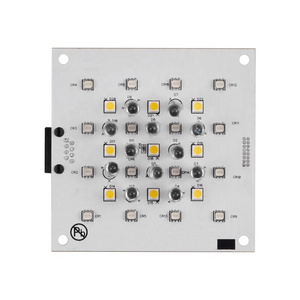

LED Lighting

-

Product name:

-

Aluminum PCB Board

-

Material:

-

Aluminum/Ceramic/FR4/Copper Base

-

Keywords:

-

PCB LED Lighting

-

MOQ:

-

1pcs

-

Service:

-

One-Stop OEM Service

-

Package:

-

Vacuum Package

-

Surface treatment:

-

HASL lead free

-

Solder Mask:

-

Green. Red. Blue. White. Black.Yellow.Grew

Quick Details

-

Base Material:

-

FR4

-

Board Thickness:

-

1.6mm

-

Model Number:

-

Aluminum PCB

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HighLeap

-

Copper Thickness:

-

1oz

-

Min. Hole Size:

-

0.2mm

-

Min. Line Width:

-

0.1mm

-

Min. Line Spacing:

-

0.1mm

-

Surface Finishing:

-

HASL/Lead free HASL

-

Board Size:

-

OEM

-

Application:

-

LED Lighting

-

Product name:

-

Aluminum PCB Board

-

Material:

-

Aluminum/Ceramic/FR4/Copper Base

-

Keywords:

-

PCB LED Lighting

-

MOQ:

-

1pcs

-

Service:

-

One-Stop OEM Service

-

Package:

-

Vacuum Package

-

Surface treatment:

-

HASL lead free

-

Solder Mask:

-

Green. Red. Blue. White. Black.Yellow.Grew

General introduction of Aluminum PCB

Among all Metal core PCBs, Aluminum PCB is the most common type. The base material consists of an aluminum core and standard FR4.

It features a thermal clad layer that dissipates heat in a highly efficient manner while cooling components and increasing the overall performance of the products. Currently, Aluminum Backed PCB is regarded as the solution to high power and tight tolerance applications.

It features a thermal clad layer that dissipates heat in a highly efficient manner while cooling components and increasing the overall performance of the products. Currently, Aluminum Backed PCB is regarded as the solution to high power and tight tolerance applications.

Advantages of Aluminum PCB

1.Environmentally Friendly: Aluminum is non-toxic and recyclable. Manufacturing with aluminum is also conducive to conserving energy due to its ease of assembly. For printed circuit board suppliers, using this metal helps maintain the health of our planet.

2.Heat dissipation: High temperatures can cause severe damage to electronics, so it is wise to use a material that can help dissipate heat. Aluminum can actually transfer heat away from vital components, thus minimizing the harmful effect it could have on the circuit board.

3.Higher durability: Aluminum provides strength and durability to a product that ceramic or fiberglass bases cannot. Aluminum is a sturdy base material that can reduce accidental breakage during manufacturing, handling, and everyday use.

4.Lightweight: For its incredible durability, aluminum is a surprisingly lightweight metal. Aluminum adds strength and resilience without adding on any additional weight.

Insulating Layer

The insulating layer is the core technology of the aluminum substrate, which mainly plays the functions of bonding, insulation and heat conduction. The aluminum substrate insulating layer is the largest thermal barrier in the power module structure. The better the thermal conductivity of the insulating layer, the more favorable it is to spread the heat generated during the operation of the device, and the lower the operating temperature of the device, so as to increase the power load of the module, reduce the volume, extend the life-span, and increase the power output .

Metal substrate

What kind of metal is used for the insulating metal substrate depends on the comprehensive consideration of the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface state and cost of the metal substrate.

In general, considering the conditions such as cost and technical performance, aluminum plate is an ideal choice. Available aluminum plates are 6061, 5052, 1060 and so on. If there are higher requirements for thermal conductivity, mechanical properties,electrical properties and other special properties, copper plates, stainless steel plates, iron plates and silicon steel plates can also be used.

2.Heat dissipation: High temperatures can cause severe damage to electronics, so it is wise to use a material that can help dissipate heat. Aluminum can actually transfer heat away from vital components, thus minimizing the harmful effect it could have on the circuit board.

3.Higher durability: Aluminum provides strength and durability to a product that ceramic or fiberglass bases cannot. Aluminum is a sturdy base material that can reduce accidental breakage during manufacturing, handling, and everyday use.

4.Lightweight: For its incredible durability, aluminum is a surprisingly lightweight metal. Aluminum adds strength and resilience without adding on any additional weight.

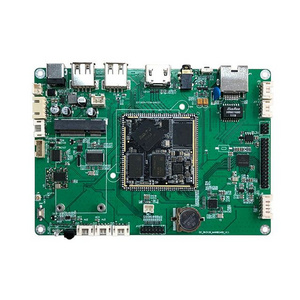

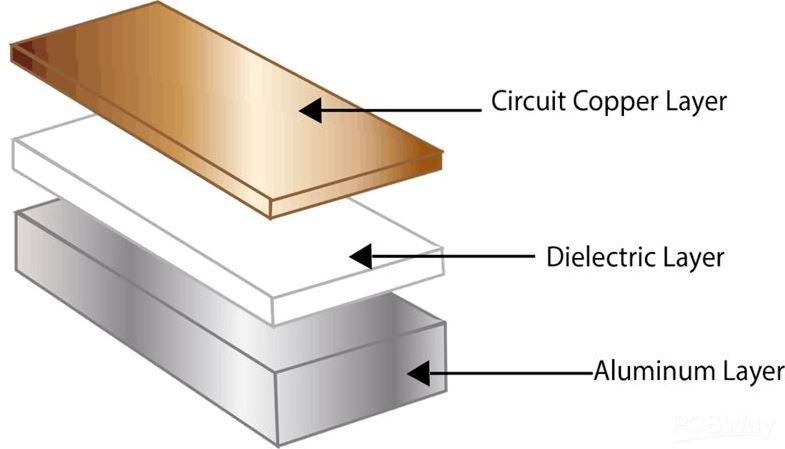

Structure of Aluminum PCB

Circuit Copper Layer

The circuit copper layer (usually using electrolytic copper foil) is etched to form a printed circuit, which is used to realize

the assembly and connection of the device. Compared with the traditional FR-4, with the same thickness and the same line width, the aluminum substrate can carry a higher current.

Circuit Copper Layer

The circuit copper layer (usually using electrolytic copper foil) is etched to form a printed circuit, which is used to realize

the assembly and connection of the device. Compared with the traditional FR-4, with the same thickness and the same line width, the aluminum substrate can carry a higher current.

Insulating Layer

The insulating layer is the core technology of the aluminum substrate, which mainly plays the functions of bonding, insulation and heat conduction. The aluminum substrate insulating layer is the largest thermal barrier in the power module structure. The better the thermal conductivity of the insulating layer, the more favorable it is to spread the heat generated during the operation of the device, and the lower the operating temperature of the device, so as to increase the power load of the module, reduce the volume, extend the life-span, and increase the power output .

Metal substrate

What kind of metal is used for the insulating metal substrate depends on the comprehensive consideration of the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface state and cost of the metal substrate.

In general, considering the conditions such as cost and technical performance, aluminum plate is an ideal choice. Available aluminum plates are 6061, 5052, 1060 and so on. If there are higher requirements for thermal conductivity, mechanical properties,electrical properties and other special properties, copper plates, stainless steel plates, iron plates and silicon steel plates can also be used.

|

PCB Capability

|

|

|

|

|||

|

Item

|

Rigid PCB

|

Flexible PCB

|

Rigi-Flex PCB

|

|||

|

Max Layer

|

60L

|

8L

|

36L

|

|||

|

Inner Layer Min Trace/Space

|

3/3mil

|

3/3mil

|

3/3mil

|

|||

|

Out layer Min Trace/Space

|

3/3mil

|

3.5/4mil

|

3.5/4mil

|

|||

|

Inner Layer Max Copper

|

6oz

|

2oz

|

6oz

|

|||

|

Out Layer Max Copper

|

6oz

|

2oz

|

3oz

|

|||

|

Min Mechanical Drilling

|

0.15mm

|

0.1mm

|

0.15mm

|

|||

|

Min Laser Driliing

|

0.1mm

|

0.1mm

|

0.1mm

|

|||

|

Max Aspect Ratio(Mechanical Drilling)

|

20:01

|

10:01

|

12:01

|

|||

|

Max Aspect Ratio(Laser Drilling)

|

1:01

|

/

|

1:01

|

|||

|

Press Fit Hole Ttolerance

|

±0.05mm

|

±0.05mm

|

±0.05mm

|

|||

|

PTH Tolerance

|

±0.075mm

|

±0.075mm

|

±0.075mm

|

|||

|

NPTH Tolerance

|

±0.05mm

|

±0.05mm

|

±0.05mm

|

|||

|

Countersink Tolerace

|

±0.15mm

|

±0.15mm

|

±0.15mm

|

|||

|

Board Thickness

|

0.4-8mm

|

0.1-0.5mm

|

±0.15mm

|

|||

|

Board Thickness Tolerance(<1.0mm)

|

±0.1mm

|

±0.05mm

|

±0.1mm

|

|||

|

Board Thickness Tolerance(≥1.0mm)

|

±10%

|

/

|

±10%

|

|||

|

Min Board Size

|

10*10mm

|

5*10mm

|

10*10mm

|

|||

|

Max Board Size

|

22.5*30 inch

|

9*14 inch

|

22.5*30 inch

|

|||

|

Contour Tolerance

|

±0.1mm

|

±0.05mm

|

±0.1mm

|

|||

|

Min BGA

|

7 mil

|

7 mil

|

7 mil

|

|||

|

Min SMT

|

7*10mil

|

7*10mil

|

7*10mil

|

|||

|

Min solder Mask Clearance

|

1.5mil

|

3mil

|

1.5mil

|

|||

|

Min Solder mask Dam

|

3mil

|

8mil

|

3mil

|

|||

|

Min Legand Width/Height

|

4/23mil

|

4/23mil

|

4/23mil

|

|||

|

Strain Fillet Width

|

/

|

1.5±0.5mm

|

1.5±0.5mm

|

|||

|

Bow&Twist

|

0.003

|

/

|

0.0005

|

|||

About HighLeap Electronic

Advantages of HighLeap Electronic

Our PCB Equipments

Our Certifications

FAQ

Q1:What kind of PCB file format can you accept for production?

Gerber, PROTEL 99SE, PROTEL DXP, CAM350, ODB+(.TGZ)

Q2:Is my PCB files safe when I submit them to you for manufacturing?

We respect customer's copyright and will never manufacture PCB for someone else with your files unless we receive written permission from you, nor we'll share these files with any other 3rd parties.

Q3:What payments do you accept ?

-Wire Transfer(T/T),Western Union,Letter of Credit(L/C)

-Paypal ,Ali Pay,Credit Cart

Q4:How to get the PCBs?

A:For small packages, we will ship the boards to you by DHL,UPS,FedEx,EMS. Door to door service! You will get your PCBs at your home.

B:For heavy goods more than 300kg, we may ship your boards by ship or by air to save freight cost. Of course, if you have your own forwarder, we may contact them for dealing with your shipment.

Q5:What is your minimum order quantity?

Our MOQ is 1 PCS.

Q6: Can we visit your company?

No problem. You are welcome to visit us in Shenzhen. Or the other factory is in GuangDong province.

Q7: How can you ensure the quality of the PCBs?

Our PCBs are 100% test including Flying Probe Test, E-test and AOI.

Gerber, PROTEL 99SE, PROTEL DXP, CAM350, ODB+(.TGZ)

Q2:Is my PCB files safe when I submit them to you for manufacturing?

We respect customer's copyright and will never manufacture PCB for someone else with your files unless we receive written permission from you, nor we'll share these files with any other 3rd parties.

Q3:What payments do you accept ?

-Wire Transfer(T/T),Western Union,Letter of Credit(L/C)

-Paypal ,Ali Pay,Credit Cart

Q4:How to get the PCBs?

A:For small packages, we will ship the boards to you by DHL,UPS,FedEx,EMS. Door to door service! You will get your PCBs at your home.

B:For heavy goods more than 300kg, we may ship your boards by ship or by air to save freight cost. Of course, if you have your own forwarder, we may contact them for dealing with your shipment.

Q5:What is your minimum order quantity?

Our MOQ is 1 PCS.

Q6: Can we visit your company?

No problem. You are welcome to visit us in Shenzhen. Or the other factory is in GuangDong province.

Q7: How can you ensure the quality of the PCBs?

Our PCBs are 100% test including Flying Probe Test, E-test and AOI.

Hot Searches