- Product Details

- {{item.text}}

Quick Details

-

Rated Power:

-

37KW

-

Dimension(L*W*H):

-

3000x2000x150mm

-

Weight (KG):

-

3500

-

apply:

-

bridge cutting machine

-

main motor power:

-

37KW

-

max.working pressure:

-

410Mpa

-

max. flow rate:

-

3.7L/min

-

max. oil pressure:

-

20Mpa

-

accumulator volume:

-

1.2L

-

way of drive:

-

AC servo

-

max. moving speed:

-

6000mm/min

-

control accuracy:

-

0.01mm

-

power supply:

-

220V 50Hz

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

APW

-

Voltage:

-

380V

-

Rated Power:

-

37KW

-

Dimension(L*W*H):

-

3000x2000x150mm

-

Weight (KG):

-

3500

-

apply:

-

bridge cutting machine

-

main motor power:

-

37KW

-

max.working pressure:

-

410Mpa

-

max. flow rate:

-

3.7L/min

-

max. oil pressure:

-

20Mpa

-

accumulator volume:

-

1.2L

-

way of drive:

-

AC servo

-

max. moving speed:

-

6000mm/min

-

control accuracy:

-

0.01mm

-

power supply:

-

220V 50Hz

-

Certification:

-

CE

CNC water jet bridge cutting machine are the most flexible and cost-effective cutting machine available. As the leader provier of waterjet cutting machine, APW's objective was to harness state-of-the-art technologies to make high-pressure abrasive jet machining practical, affordable, and easy to use.

CNC water jet bridge cutting machine can cut almost any material. Pure water jets can quickly and accurately cut soft materials such as rubber, foam and other gasket material. Abrasive water jets can cut almost any other material over a very wide range of thichness:

The features cnc glass machine

1 It does not cause heat effect or detormation or tiny cracks

2 It can cut any complex and flat figures

3 Narrow kerfs

4 Smooth incision

5 Minimize dust and toxic fumes, provice healthier working environment

6 It can be adjested easily and quickly by the designs and materials

7 Low processing cost in unit time

8 Components are of high quality and spare parts are cheap

9 Drilling holes to avoid water permeate the composite materials

10 Reduce setting time and fixture cost

The cutting speed for cnc water jet bridge cutting machine

CNC water jet bridge cutting machine cutting speed varies depending on the material, thickness, desired cut quality, water pressure and the machine itself configuration. Generally for APW waterjet, you could find the following speed just for your reference.

| Material | Thickness(mm) | Cutting speed of 300Mpa pump(mm/min) | Cutting speed of 380Mpa pump(mm/min) |

| Marble | 20 | 300 | 380 |

| 30 | 200 | 300 | |

| Granite | 20 | 250 | 330 |

| 30 | 150 | 200 | |

| Glass Brick | 12 | 800 | 960 |

| Glass | 5 | 1200 | 1500 |

| 10 | 500 | 600 | |

| 20 | 350 | 420 | |

| Glue Chipped Glass | 10 | 450 | 540 |

| Sponge | 50 | 5000 | 6000 |

| Foam | 50 | 5000 | 6000 |

| Wood | 10 | 1000 | 1200 |

| 50 | 200 | 240 | |

| Steel | 2 | 600 | 720 |

| 4 | 400 | 500 | |

| 6 | 300 | 420 | |

| 8 | 200 | 300 | |

| 10 | 120 | 200 | |

| 15 | 75 | 120 | |

| 20 | 30 | 50 | |

| 60 | 12 | 20 | |

| Laminates | 10 | 1500 | 1800 |

| Aluminum | 5 | 350 | 500 |

| Copper | 5 | 350 | 420 |

|

Glass Fiber Reinforced Plastic |

2 | 1200 |

1500

|

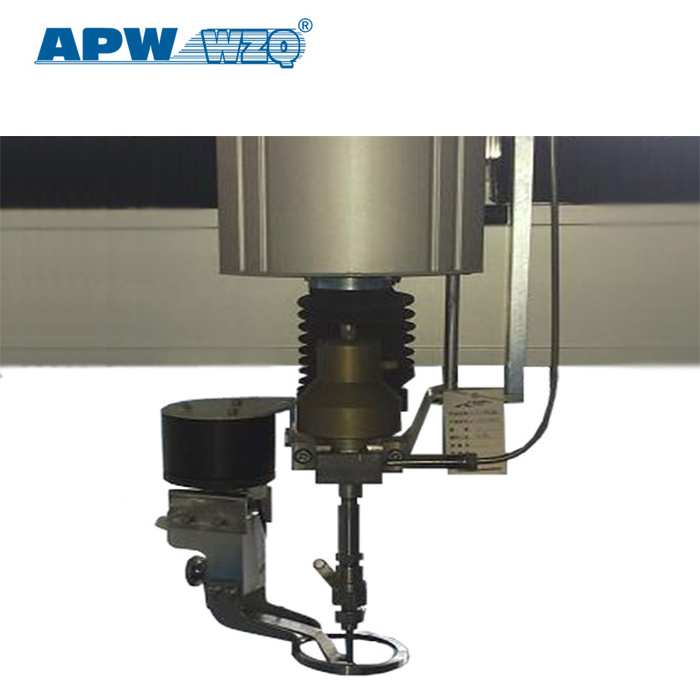

cnc water jet bridge cutting machine is made up of several critical key componnents, such as intensifier pump; cutting table with cutting head; CNC controller; auto abrasive delivery system.

Dual-Core Waterjet Debut

The new APW "Dual-Core" pump of cnc glass cutter machine is equipped with dual intensifiers imported from the USA. The two intensifiers are able to work by alternative way. It significantly reduces the maintenance time, and expands the life span of the pump.

Imported components

We adopt the imported component of cnc glass machine like Rexroth hydraulic pump; USA intensifier; Siemens motor;Omron PLC; Yaskawa servo drive; Yuken direction control valves etc. The whole parts of Intensifier are assembled in USA (not just some parts), most of the smaller parts are also imported from USA to ensure its good stability during cutting, durability and long working service life.