- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

1.5-3mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Dingbo

-

Voltage:

-

380V 50Hz 3phases(customized)

-

Dimension(L*W*H):

-

L*W*H

-

Weight:

-

13T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Product name:

-

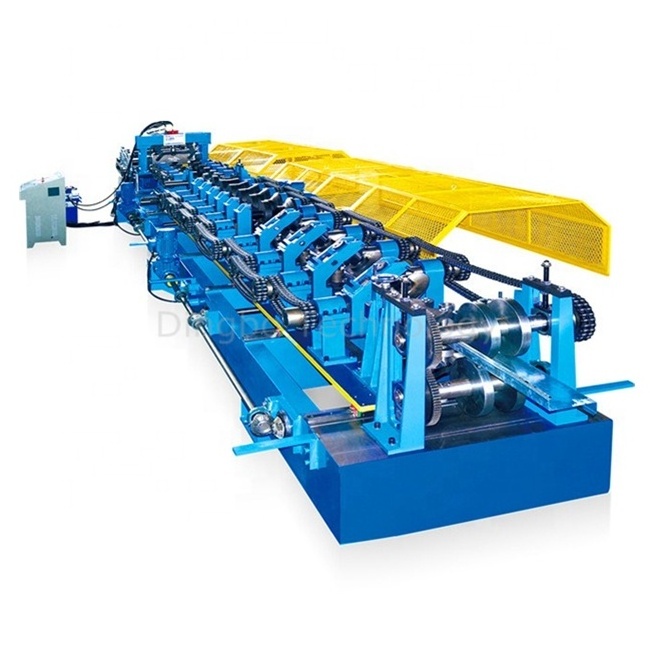

Galvanized Steel C Z U Channel Purlin Roll Forming Machine

-

Roller driven type:

-

Chain Transmission

-

Control system:

-

PLC

-

Raw material:

-

Galvanized Sheet

-

Roller material:

-

High-grade 45# Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 Mov

-

Certification:

-

CE ISO SGS

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

1.5-3mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Dingbo

-

Voltage:

-

380V 50Hz 3phases(customized)

-

Dimension(L*W*H):

-

L*W*H

-

Weight:

-

13T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Product name:

-

Galvanized Steel C Z U Channel Purlin Roll Forming Machine

-

Roller driven type:

-

Chain Transmission

-

Control system:

-

PLC

-

Raw material:

-

Galvanized Sheet

-

Roller material:

-

High-grade 45# Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 Mov

-

Certification:

-

CE ISO SGS

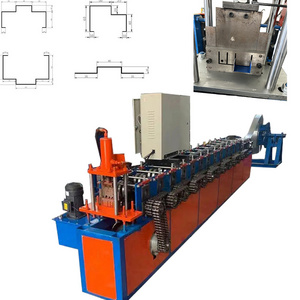

Galvanized Steel C Z U Channel Purlin Roll Forming Machine for Building Material Machinery

Main features

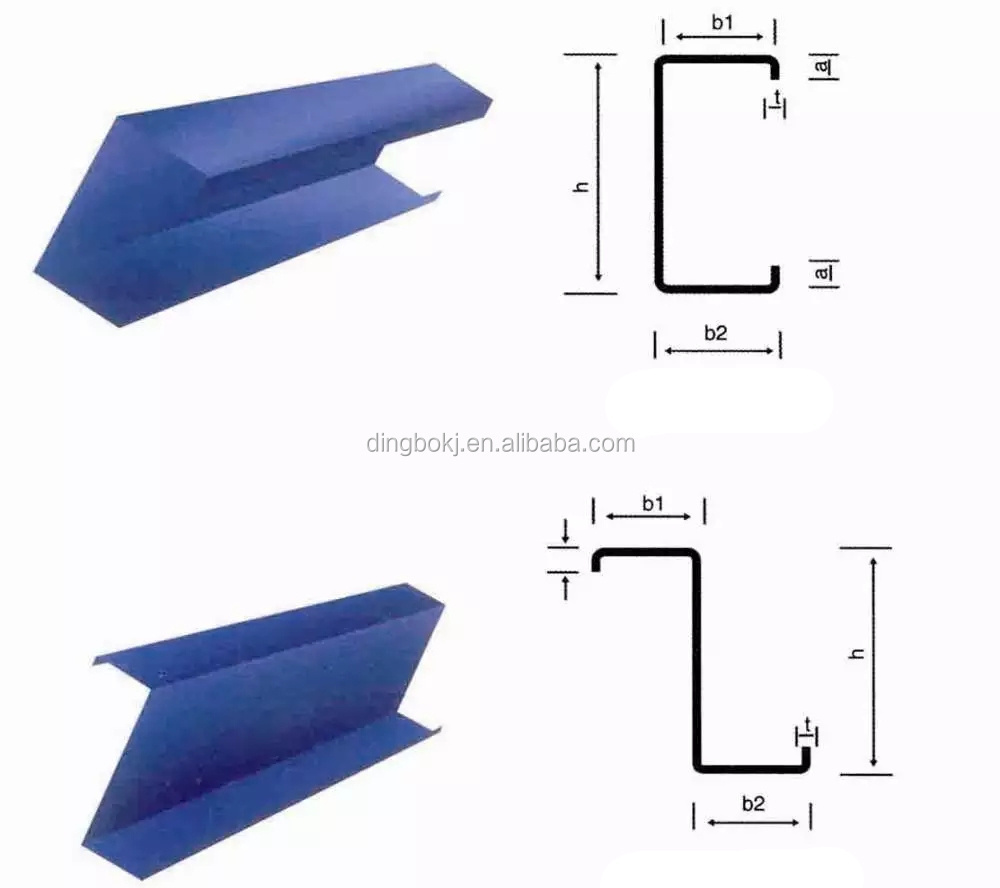

The g alvanized steel CZ purlins is processed by the CZ Interchangdable purlin roll forming machine of hot rolled plate, the wall is thin and light, the section has good performance and high strength, and the material is GI. Common steel purlins have Z - shaped steel purline and C - shaped steel purline. The steel purline is the secondary bearing member in the roof structure system, which carries the roof load to the steel frame.

Working flow

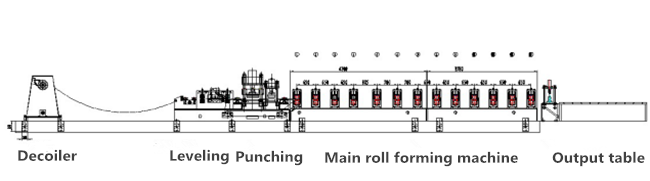

Decoiler -- Leveling -- Punching and Cutting -- Main roll forming -- Products to run out table

Technical parameters

|

Article No. |

Item Name |

Specification |

|

1 |

Width of feeding material |

According the profile |

|

2 |

Thickness of feeding material |

Max 3.0mm |

|

3 |

Purlin Width |

100-300mm |

|

4 |

Purlin Height |

40-80mm |

|

5 |

Roller station |

14 stations |

|

6 |

Roller material |

Gcr15, quench treatment hardness 55-58 |

|

7 |

Forming speed |

10-15 m/min |

|

8 |

Main motor |

15 kw |

|

9 |

Driving way |

Chain transmission |

|

10 |

Hydraulic power |

5.5kw |

|

11 |

Punching |

Hydraulic pre-punching |

|

12 |

Punching mould material |

Cr12 |

|

13 |

Cutting system |

Hydraulic pre-cutting |

|

14 |

Blade material |

Cr12 |

|

15 |

Tolerance |

+-1.5mm |

|

16 |

Voltage |

380V 50Hz 3phases |

|

17 |

Machine height |

13 tons |

|

18 |

Machine length |

10m |

|

19 |

Control |

P anasonic PLC |

|

20 |

Decoiler |

5 tons |

The CZ purlins are widely used in various industrial factory, beauty spot, holiday village building, hotel, exhibition, easy steel building manufacturing, and have features such as nice appearance and durable.

The control box, hydraulic station and other spare parts are packed with plywood box.

Equipment fix with container use steel wire. Protect the machine didn't broken in the delivery