- Product Details

- {{item.text}}

Quick Details

-

Power:

-

6KW

-

Dimension(L*W*H):

-

4940x1300x1690mm

-

Weight:

-

1800

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine name:

-

DSP-200B Full-auto Wet Tissue Folding and Packing Machine(1pc/pack)

-

After Service:

-

Long Term Spare Part

-

Type:

-

Single Piece Wet Tissue Machine (1pc/pack)

-

Wetting system:

-

Automatic Wetting Liquid

-

Product name:

-

Automatic Hand Towel Making Machine (CE Approved)

-

Port:

-

Xiamen

-

Usage:

-

Sealing Packaging Machine

-

Speed:

-

180-220 Package/minute

-

Keyword:

-

wet wipes making machine

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

DACHANG

-

Voltage:

-

380V 50HZ

-

Power:

-

6KW

-

Dimension(L*W*H):

-

4940x1300x1690mm

-

Weight:

-

1800

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine name:

-

DSP-200B Full-auto Wet Tissue Folding and Packing Machine(1pc/pack)

-

After Service:

-

Long Term Spare Part

-

Type:

-

Single Piece Wet Tissue Machine (1pc/pack)

-

Wetting system:

-

Automatic Wetting Liquid

-

Product name:

-

Automatic Hand Towel Making Machine (CE Approved)

-

Port:

-

Xiamen

-

Usage:

-

Sealing Packaging Machine

-

Speed:

-

180-220 Package/minute

-

Keyword:

-

wet wipes making machine

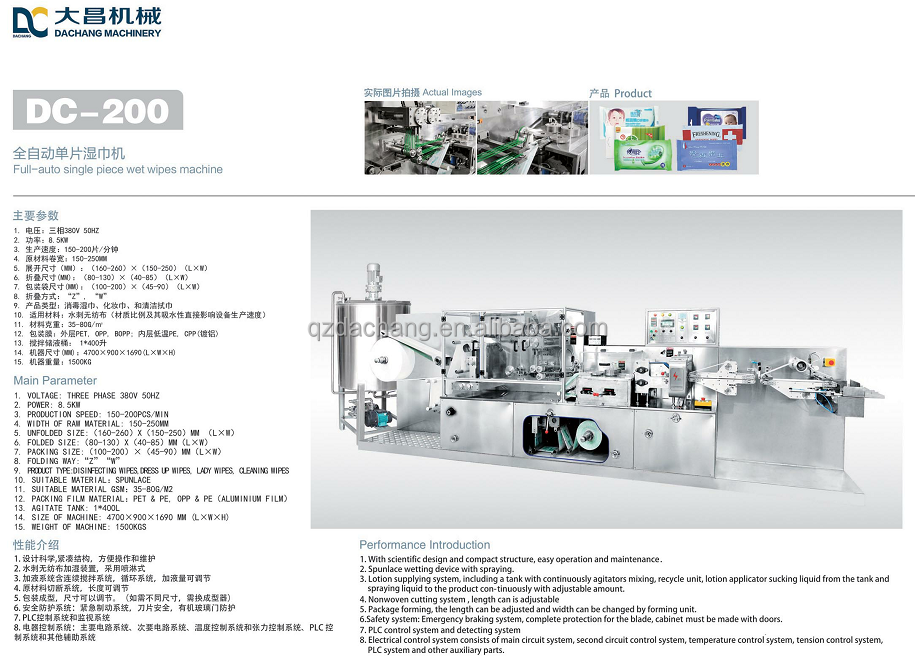

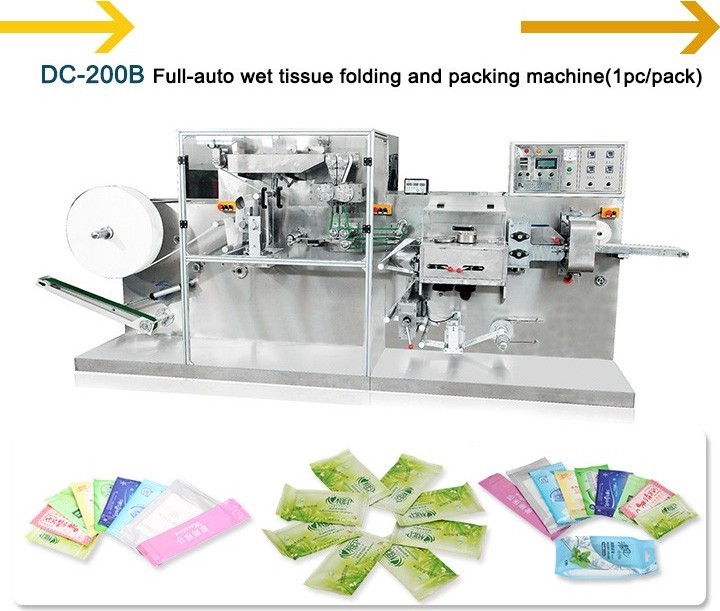

(1)Main technical parameter

1. Power: 380V 50HZ

2. Power supply: 6KW

3. Production speed: 200-250pcs/min

4. Unfolded size (mm): (160-260)×(150-200) (L×W)

5. Folded size(mm): (80-130)×(50-80) (L×W)

6. Packing size(mm): (100-200)×(60-80) (L×W)

7. Folding type: “Z”,“W”

8. Product type: antiseptic cleansing wipe, make-up wipe, cleaning wipe.

9. Suitable material: Nonwoven fabric, air laid paper

10.Weight of raw material: 40 -80g/m2

11. Raw material roll width: 150-200mm

12. Packing film: PE & PET, OPP & PE(aluminum film)

13.Wetting system: Tank with agitator

14.Volume of Tank: 400L

15. Tank size(mm):

900x900x1900

16. Installation space (mm): 4940*1300*1690(L×W×H)

17. Total weight: 1800kg

18. Production efficiency: >=85%

29. Wastege rate: <=1%

(2) Main Features

1. With scientific design and compact structure, easy operation and maintenance.

2. Spunlace wetting, adopt founder form.

3. Lotion supplying system, including a tank with continuously agitators mixing, recycle unit, lotion applicator sucking liquid from the tank and spraying liquid to the product continuously with adjustable amount.

4. Nonwoven cutting system, length can be adjustable.

4. Package forming, the length can be adjusted and width can be changed by forming unit.

5.Safety system: Emergency braking system, complete protection for the blade, cabinet must be made with doors.

6. PLC control system and detecting system.

7. Electrical control system consists of main circuit system, second circuit control system, temperature control system, tension control system, PLC system and other auxiliary parts.

(1)

Technical Support

1. Free consultant service, help customers to make project feasibility analysis.

2.

We provide the relevent product information of the series for customer’s reference.

3. We offer the designing, installment drawing and necessary information for production according to customer’s real situation.

4.

We inform the models, technical index and request, suppliers and reference price of all necessary raw materials for production.

5.

We advise customers how to solve the usual machine fault.

6.

We can supply the technicians to operate the machine.

(2)

After-sale Service

1.

The machines are tested and have trial production in our factory before leaving our factory and they are shipped out only after the customers are satisfied with them.

2.

When the machines are tested, our technicians will train the customers’ technicians in theory and

practice till they grasp the skills.

3.

When the machines are delivered to the customers, we can go to customer’s factory to install, test the machines, and to train again before the operation staff start working.

4.

During this period of one year war

r

anty, if the machines were damaged by non-artificial reasons, we are responsible for repairing or changing parts.

5.

During this period of wa

r

ranty, if there is something wrong with the machine, we are responsible to provide project for solving this problem at the soonest, and help customers to restore production as soon as possible.

6.

After the warranty, we charge only cost price for maintaining the machines within three years.

7.

Other after-sale terms can be agreed by buyer and seller in addition.