- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380

-

Dimension(L*W*H):

-

1180x1140x1250

-

Weight:

-

400 KG

-

Color:

-

Customer Requirement

-

Factory visit:

-

Welcome

-

After-sales Service Provided:

-

Video technical support, Online support

-

Certification:

-

ISO CE

-

Feeding size:

-

< 6mm

-

Standard feeding concentration:

-

35%

-

Application:

-

Gold/Platinum/Mercury/Palladium/Tantalum/Copper/Silver

Quick Details

-

Production Capacity:

-

2-3t/h, 10-40t/h

-

Place of Origin:

-

Henan China

-

Brand Name:

-

KLD

-

Voltage:

-

380

-

Dimension(L*W*H):

-

1180x1140x1250

-

Weight:

-

400 KG

-

Color:

-

Customer Requirement

-

Factory visit:

-

Welcome

-

After-sales Service Provided:

-

Video technical support, Online support

-

Certification:

-

ISO CE

-

Feeding size:

-

< 6mm

-

Standard feeding concentration:

-

35%

-

Application:

-

Gold/Platinum/Mercury/Palladium/Tantalum/Copper/Silver

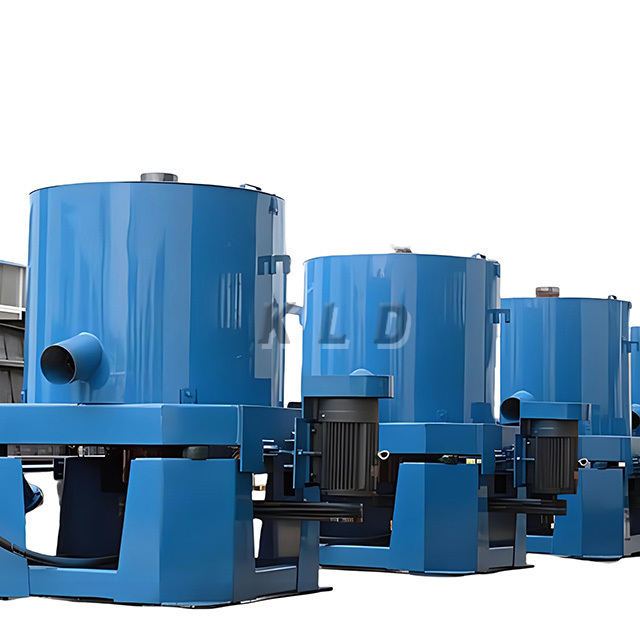

Product Overview

KLD Concentrator Working Principle:

The hollow shaft of KLD Concentrator can be driven by electrical motor transmission part through belt driving, making the rotation inner sleeve rotate in a high speed to produce centrifugal force. The slurry will be fed into the rotation inner sleeve through feeding pipe, and the slurry particle will be separated under the action of centrifugal force field. The heavy mineral will be remained in the cell guide of rotation inner sleeve, and the light mineral will be discharged through the tailings launder. After one shift work and stop running, the concentrate will be discharged through the concentrate discharge outlet.

It can be used not only for placer gold mining, but also for hard rock mining to recover the natural gold, replacing amalgamation. It is also used to recover gold from the old tailings.

Product case

Product Description:

【Introduction】: Gold centrifugal concentrator also called kLD concentrator is a new type of gravity concentration equipment, used in the gold mining industry. It is used for the recovery of fine part icles of free gold, meaning gold that does not require gold cyanidation for recovery.

【Introduction】: Gold centrifugal concentrator also called kLD concentrator is a new type of gravity concentration equipment, used in the gold mining industry. It is used for the recovery of fine part icles of free gold, meaning gold that does not require gold cyanidation for recovery.

【

Feeding size (mm)

】:0~6

【 Feeding density (%) 】:0~50%

【 Backwash water (t/h) 】:4-6

【 Feeding density (%) 】:0~50%

【 Backwash water (t/h) 】:4-6

【

Pressure water(Mpa)

】:0.12

Working principle

(1).Central transmission shaft is driven by motor through belt, and then make the inner concentrate cone rotate in high speed.

(2).Fluidization water is introduced into the concentrate cone through central transmission shaft, and then spraying water to ring groove from inner cone holes, called backwash water. The water pressure level in separation process: 0.03-0.06Mpa.

(3).ineral materials enter into the inner cone groove by feeding pipe, under the high rotating configuration force, heavy ores will be deposited on the groove but the light ores will go upside along the cone liner, and finally going into tailing discharging pipe from cone upper surroundings.During the separation process, make sure the concentration discharging pipe is closed.

(4).After a cycle process, close down the machine and open the concentration pipe to collect the gold concentration.

(2).Fluidization water is introduced into the concentrate cone through central transmission shaft, and then spraying water to ring groove from inner cone holes, called backwash water. The water pressure level in separation process: 0.03-0.06Mpa.

(3).ineral materials enter into the inner cone groove by feeding pipe, under the high rotating configuration force, heavy ores will be deposited on the groove but the light ores will go upside along the cone liner, and finally going into tailing discharging pipe from cone upper surroundings.During the separation process, make sure the concentration discharging pipe is closed.

(4).After a cycle process, close down the machine and open the concentration pipe to collect the gold concentration.

Product Advantages:

Application shows that the recovery rate can be as high as90% in tin ore, Pb ore, antimony ore, sliver ore, gold ore,etc.especially for the case less than 2.5mm heavy ores, can reach to 92%.

Application shows that the recovery rate can be as high as90% in tin ore, Pb ore, antimony ore, sliver ore, gold ore,etc.especially for the case less than 2.5mm heavy ores, can reach to 92%.

Technical Parameters

|

Model

|

STL-30

|

STL-60

|

STL-80

|

STL-100

|

|

Capacity (t/h)

|

2-3

|

10-20

|

35-45

|

60-120

|

|

Feeding size (mm)

|

0-4

|

0-6

|

0-6

|

0-6

|

|

Feeding density (%)

|

0-50%

|

0-50%

|

0-50%

|

0-50%

|

|

Backwash water (t/h)

|

4-6

|

10-15

|

17-25

|

40-60

|

|

Output(kg/time)

|

10-20

|

30-40

|

60-70

|

70-80

|

|

Motor power(kw)

|

1.5

|

5.5

|

11

|

18.5

|

|

Revolution

|

600

|

460

|

400

|

360

|

|

Pressure water(Mpa)

|

0.12

|

0.25

|

0.35

|

0.4

|

|

Dimension(mm)

|

1180x1140x1250

|

1970x1670x1750

|

2300x1800x2200

|

2500x2000x2400

|

|

Weight (kg)

|

400

|

1300

|

2000

|

2500

|

Maybe you are interested in

wet pan mill

Sand washer

Impact crusher

Ball Mill

Hammer crusher

cone crusher

Grindind Mill

Mobile Hammer Crusher

Mobile Jaw Crusher

About Us

Our Company

Henan Kailide Machinery Co.,ltd

is a professional mining machinery manufacturer and provides all kinds of mining equipment for client, which includes ore beneficiation equipment, crushing equipment,sand making equipment, powder grinding equipment and widely used in various industries such as metallurgy, mine, chemistry, building material, coal, refractory and ceramics. We are always insisting on international advanced technical cooperation and communication, and introduce advanced technology from Germany, Finland, and make digestion and absorption to improve our products' quality continuously. While expanding domestic market percentage constantly, our products are being exported to Sudan, Russia, Pakistan, Georgia, Kazakhstan, South Korea, Australia, Indonesia, Malaysia, Vietnam, Africa and so on, more than 50 countries and regions totally.

Packing and delivery

Our Factuary

FAQ

Q1: Are you trading company or manufacturer?

A1:We are professional manufacturer, and our factory mainly produce crushing and milling equipment, wood crushing equipment,construction equipment, brick production equipment, etc. Our products have been exported to more than 50 countries of Asia, South America, Africa, and get a good reputation in the world.

Q2: Installation?

A2:Our senior engineer will supply installation and training service on-line or on-site.

Q3: What about Warranty?

A3:Vansen Machinery grants our customers a twelve-month-period warranty from the date of delivery for machines exported from us.During the warranty period, in case any defect of material or workmanship occurred with spare parts in normal operation, we will at our discretion replace or repair the defective parts freely.

Q4: What about After-sale service?

A4:All equipment produced by Vansen is of the highest standard and our customers rarely experience mechanical failures. If there are any problems, our engineers and technicians will respond with in 12 hours of customer notification.

Q5. For providing you the right model, we need to know the following information:

A5:

(1)* What is the raw material for the production line?

(2)* What is the capacity per hour you required?

(3)* What is the maximum input size of the raw material?

A1:We are professional manufacturer, and our factory mainly produce crushing and milling equipment, wood crushing equipment,construction equipment, brick production equipment, etc. Our products have been exported to more than 50 countries of Asia, South America, Africa, and get a good reputation in the world.

Q2: Installation?

A2:Our senior engineer will supply installation and training service on-line or on-site.

Q3: What about Warranty?

A3:Vansen Machinery grants our customers a twelve-month-period warranty from the date of delivery for machines exported from us.During the warranty period, in case any defect of material or workmanship occurred with spare parts in normal operation, we will at our discretion replace or repair the defective parts freely.

Q4: What about After-sale service?

A4:All equipment produced by Vansen is of the highest standard and our customers rarely experience mechanical failures. If there are any problems, our engineers and technicians will respond with in 12 hours of customer notification.

Q5. For providing you the right model, we need to know the following information:

A5:

(1)* What is the raw material for the production line?

(2)* What is the capacity per hour you required?

(3)* What is the maximum input size of the raw material?

Hot Searches