- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LFBJMB

-

Model Number:

-

LF-BJMBCC20221012

-

Product name:

-

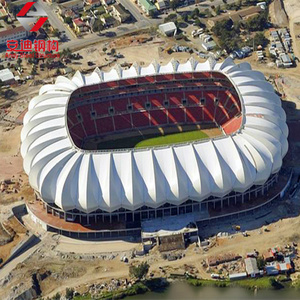

Stadium Roof Steel Structure

-

Installation:

-

Supervision

-

Roof Cladding:

-

Color steel sheet(sandwich panel)

-

Drawing design:

-

SAP2000/MST/PKPM /3D3S/

-

Connection Type:

-

Bolt Ball connection

-

Steel Frame Durable Years:

-

50 years

-

Surface treatment:

-

Hot Dip Gavalnized

-

Purlin:

-

C/Z Galvanized Steel(Q235)

-

Material:

-

Q235B/Q355B Low Carbon Steel

-

Structure type:

-

Steel Sturcture/Space Frame/Truss

Quick Details

-

Grade:

-

Light Steel Structure

-

Tolerance:

-

±20%

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LFBJMB

-

Model Number:

-

LF-BJMBCC20221012

-

Product name:

-

Stadium Roof Steel Structure

-

Installation:

-

Supervision

-

Roof Cladding:

-

Color steel sheet(sandwich panel)

-

Drawing design:

-

SAP2000/MST/PKPM /3D3S/

-

Connection Type:

-

Bolt Ball connection

-

Steel Frame Durable Years:

-

50 years

-

Surface treatment:

-

Hot Dip Gavalnized

-

Purlin:

-

C/Z Galvanized Steel(Q235)

-

Material:

-

Q235B/Q355B Low Carbon Steel

-

Structure type:

-

Steel Sturcture/Space Frame/Truss

Product Description

Advantages of

using space frame structure to build stadium

1. Lightweight and efficient: Space frame structures are made up of lightweight materials such as steel or aluminum, which makes them highly efficient in terms of material usage. This reduces the overall weight of the structure, making it more cost-effective in terms of materials and transportation.

2. Large spans: Space frame structures can span large distances without the need for internal columns or support walls. This allows for unobstructed views and maximizes the usable space within the stadium. It also provides flexibility in the design, allowing for changes in seating arrangements or future expansions.

3. Quick construction: Space frame structures can be prefabricated off-site and then assembled on-site, which significantly reduces construction time compared to traditional building methods. This is particularly advantageous for stadiums, where construction deadlines are often tight and there is a need for quick completion.

4. Durability and strength: Space frame structures are known for their high strength-to-weight ratio, making them capable of withstanding heavy loads, such as the weight of the roof or the pressure from wind and snow. This ensures the long-term durability and safety of the stadium.

5. Architectural flexibility: Space frame structures offer a wide range of design possibilities due to their modular nature. They can be easily customized to accommodate various architectural styles, allowing for unique and visually appealing stadium designs.

6. Cost-effective: Despite the initial investment in design and fabrication, space frame structures can be cost-effective in the long run. Their lightweight nature results in reduced foundation costs, and their quick construction time translates to lower labor costs. Additionally, the use of lightweight materials can lead to savings in transportation and maintenance costs.

7. Sustainability: Space frame structures are often considered sustainable due to their efficient use of materials and energy. They require fewer raw materials, generate less construction waste, and can be easily dismantled and reused in other projects. Additionally, the large spans provided by space frames allow for natural lighting and ventilation, reducing the need for artificial lighting and HVAC systems.

Overall, using space frame structures to build stadiums offers advantages in terms of efficiency, flexibility, durability, and sustainability. These factors make them a popular choice for modern stadium construction.

Certifications

Specification

|

Standard

|

GB

|

|

Grade

|

steel(Q235/Q355B)

|

|

Place of Origin

|

China

|

|

Brand Name

|

LF-BJMB

|

|

Type

|

Light

|

|

Application

|

STEEL STRUCTURE

|

|

Tolerance

|

±5%

|

|

Processing Service

|

Bending, Welding, Decoiling, Cutting, Punching

|

|

Delivery Time

|

31-45 days

|

|

Color

|

Customized Color

|

|

Material

|

Q235B/Q355B Low Carbon Steel

|

|

Installation

|

Supervision

|

|

Feature

|

Environmental-friendly

|

|

Surface treatment

|

1. Painting 2. Galvanized

|

|

Size

|

Customzation Size

|

|

Life span

|

50Years

|

|

Structure type

|

Light Steel Structre

|

Factory scene

Packing & Delivery

Special export packing. Strong enough for sea transportation.

Hot Searches