- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 50HZ

-

Power:

-

1.5KW

-

Dimension(L*W*H):

-

8000*3000*2000MM

-

Weight:

-

1500

-

Raw material:

-

pp pellets

-

Straw Diameter:

-

0.5-12mm

-

Keyword:

-

straw production line

-

Capacity:

-

35-100kg/h

-

Automaticity:

-

Full-antomatic

-

Color:

-

Blue or customized

-

Final Products:

-

straws

-

Control:

-

Inverter or PLC or Servo motor

-

Model:

-

350type

-

Machine Speed:

-

0-1500pcs/min

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Deedo

-

Marketing Type:

-

New Product 2023

-

Voltage:

-

220V 50HZ

-

Power:

-

1.5KW

-

Dimension(L*W*H):

-

8000*3000*2000MM

-

Weight:

-

1500

-

Raw material:

-

pp pellets

-

Straw Diameter:

-

0.5-12mm

-

Keyword:

-

straw production line

-

Capacity:

-

35-100kg/h

-

Automaticity:

-

Full-antomatic

-

Color:

-

Blue or customized

-

Final Products:

-

straws

-

Control:

-

Inverter or PLC or Servo motor

-

Model:

-

350type

-

Machine Speed:

-

0-1500pcs/min

Products Description

Lollipop straw Stick extrusion line/making machine /production line

1、Deedo brand series machine is composed of extruder, 2 sets of standard mould,cooling unit ,hauling and rotary cutting device(double frequency conversion speed regulator)

1、Deedo brand series machine is composed of extruder, 2 sets of standard mould,cooling unit ,hauling and rotary cutting device(double frequency conversion speed regulator)

2、Specification of screw of extruder : Diameter is 50 MM(important parts such as screw and cylinder adopts superior alloy steel with nitrogen treatment).

3、 Material : 38CrMoAIA (nitrogen treatment ,depth 0.2-0.7 meters)

4、 Diameter of Sub-screw : 25MM ,Aspect ratio:20:1

3、 Material : 38CrMoAIA (nitrogen treatment ,depth 0.2-0.7 meters)

4、 Diameter of Sub-screw : 25MM ,Aspect ratio:20:1

Details Images

Main extruder

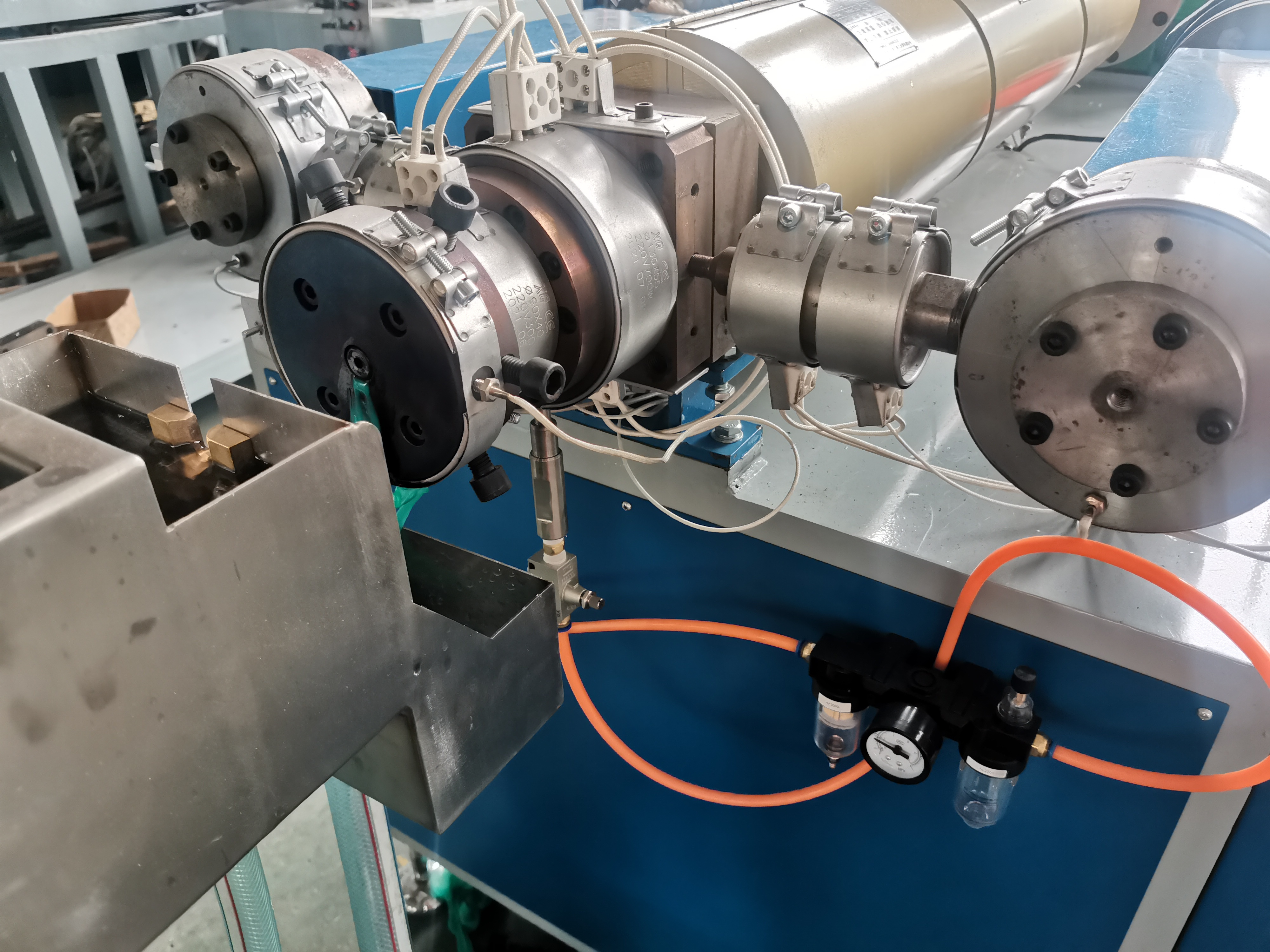

Die mould

Die mould and heating ring

Haul-off and cutter machine

Water cooling tank

Cutter and blades

Gear box

Feeding hopper

Main Features

|

Plastic Stick extrusion machine

|

|

|

|

|

||||

|

Name

|

SJ50 Plastic Stick extrusion machine

|

|

|

|

||||

|

Model

|

|

SJ50

|

SJ50/25

|

SJ50/25/25

|

||||

|

Description

|

1. Main parts are: extruder, cooling water tank, vacuum shaping equipment, air compressor, hauling cutting system, single color,

bicolor or tricolor pipes can be realized. |

|

|

|

||||

|

|

2. Main screw diameter: 50mm, important parts such as screw and cylinder adopts superior alloy steel with nitrogen treatment,

38CrMoAlA (nitrogen treatment, depth 0.2~0.7mm) |

|

|

|

||||

|

|

3. Aspect ratio: 28:1

|

|

|

|

||||

|

|

4. Diameter of sub-screw:25mm, Aspect ratio: 20:1

|

|

|

|

||||

|

|

5. Extruding power: 11kw (frequency conversion control)

|

|

|

|

||||

|

|

6. The die undergoes nitride hardening treatment for a long service time

|

|

|

|

||||

|

|

7. The water tank and the surface of cutting machine are made of 304 stainless steel

|

|

|

|

||||

|

|

8. The main extruder’s screw designed to suit plastic material specified. Tube dies head assembly manufactured in tool steel.

|

|

|

|

||||

|

|

9. All the electrical parts use SCHNEIDER or SIEMENS or Delta

|

|

|

|

||||

|

Power Supply

|

Main screw

|

380v ,3phase,50hz,7.5kw(VFD)

|

|

|

||||

|

|

Sub-screw

|

/

|

0.75kw

|

0.75×2kw

|

||||

|

|

Heating

|

7kw

|

9.56kw

|

12kw

|

||||

|

|

Hauling motor

|

0.75kw(VFD)

|

|

|

||||

|

|

Cutting motor

|

0.75kw(VFD)

|

|

|

||||

|

|

Total power

|

16.5kw

|

20kw

|

22.5kw

|

||||

|

Temperature Controller

|

|

5 sets

|

8 sets

|

11 sets

|

||||

|

Electric control cabinet

|

|

1 set

|

1 set

|

1 set

|

||||

|

Automatic Counting Device

|

|

1 set

|

1 set

|

1 set

|

||||

|

Way of Hauling

|

|

By rubber roller

|

|

|

||||

|

Way of cutting

|

|

Rotatory cutting length range 50-300mm

|

|

|

||||

|

Cooling water tank

|

Usually 4.4m, can be adjusted up&down, right &left, forward&backward. Made of superior stainless teel

|

|

|

|

||||

|

Option

|

Vacuum pump (0.75kw)

|

|

Air compressor (2kw)

|

|

||||

|

Sticks Sepc

|

Material

|

PLA PP PE etc

|

|

|

||||

|

|

Stick Diameter

|

2mm~13mm can be custiomized for special requirement

|

|

|

||||

|

|

Stick Length

|

Customizable

|

|

|

||||

|

|

Speed

|

600~1000pcs/min (product rate : 20kg/h-30kg/h

|

|

|

||||

|

|

Color

|

Single

|

Two colors

|

Three colors

|

||||

|

|

Straight or spiral

|

√

|

√

|

√

|

||||

|

|

Cutting End

|

90°/90°,90°/45°,90°/60°,45°/45°,60°/60

|

|

|

||||

|

Dimension

|

L*W*H

|

8m*1m*1.7m

|

8m*1.5m*1.7m

|

8m*2m*1.7m

|

||||

|

Weight

|

|

1500kg

|

1700kg

|

2000kg

|

||||

Final Product

Certifications

Software patent certificate

patent certificate

Hot Searches