- Product Details

- {{item.text}}

Quick Details

-

Power:

-

50kw

-

Dimension(L*W*H):

-

According to detail

-

Weight:

-

22000 kg

-

Product name:

-

Concrete Mixing Plant

-

Capacity:

-

60m3/h

-

Batching Machine:

-

PLD1600 Batching Machine

-

Concrete Mixer:

-

Js500 Twin Shaft Forced Mixer

-

Material:

-

Q235B Steel

-

Control system:

-

Siemens PLC+PC

-

screw converyor:

-

8m*219mm

-

Adapt voltage:

-

Three-phase/220V

-

control system:

-

panel control

-

After-sales Service Provided:

-

Video Technical Support

Quick Details

-

Machine Type:

-

Production line

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QIC

-

Power:

-

50kw

-

Dimension(L*W*H):

-

According to detail

-

Weight:

-

22000 kg

-

Product name:

-

Concrete Mixing Plant

-

Capacity:

-

60m3/h

-

Batching Machine:

-

PLD1600 Batching Machine

-

Concrete Mixer:

-

Js500 Twin Shaft Forced Mixer

-

Material:

-

Q235B Steel

-

Control system:

-

Siemens PLC+PC

-

screw converyor:

-

8m*219mm

-

Adapt voltage:

-

Three-phase/220V

-

control system:

-

panel control

-

After-sales Service Provided:

-

Video Technical Support

Products Description

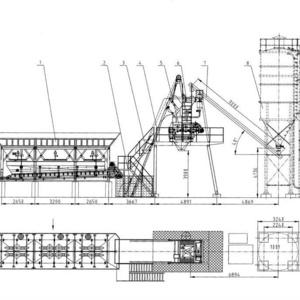

60m3/h concrete batching plant automatic ready mix batching plant Aggregate Batching Station

The mixing plant is mainly used in concrete construction projects, the main purpose is to mix and mix concrete, also called concrete mixing plant. HZS series commercial concrete mixing plant adopts internationally popular modular quick-installation structure, high-efficiency imported or domestic mixing main engine, dual-machine dual-control microcomputer control mode, anti-noise, anti-dust, and environmental protection design. It is a new generation of cement concrete mixing equipment. It is suitable for urban and rural ready-mixed concrete, roads and bridges, water conservancy, airports, ports and other large-scale infrastructure projects and places with high requirements for concrete. mobile self-loading

Working Principle

HZS concrete batching plant is composed of batching, mixing, electric control system and other parts. Through more accurate measurement of materials, it can produce high-quality concrete. They are widely used in construction works, road works, bridge works and precast concrete plants.

Product Paramenters

|

Model

|

HZS25-30

|

HZS35-40

|

HZS50-60

|

HZS75-85

|

HZS90-100

|

||||

|

Capacity

|

25-30m3/h

|

35-40m3/h

|

50-60m3/h

|

75-85m3/h

|

90-100m3/h

|

||||

|

Mixing system

|

Twin shaft concrete mixer

|

|

|

|

|

||||

|

Aggregate feeder

|

Belt conveyor

|

|

|

|

|

||||

|

After-sale service

|

Erection & commissioning, operator training

|

|

|

|

|

||||

|

Warranty

|

12 months after erection

|

|

|

|

|

||||

|

Concrete mixer

|

JS500

|

JS750

|

JS1000

|

JS1500

|

JS2000

|

||||

|

Discharging volume

|

500L

|

750L

|

1000L

|

1500L

|

2000L

|

||||

|

Mixing circle

|

72s

|

|

|

|

|

||||

|

Max. mixing size

|

80/60mm

|

|

|

|

|

||||

|

Aggregate Bins

|

4x4m3

|

4x5m3

|

4x6m3

|

4x7m3

|

4x8m3

|

||||

|

Weighing system

|

Water, Cement, Additive

|

|

|

|

|

||||

|

Control System

|

SIEMNS PLC+PC

|

|

|

|

|

||||

|

Weighing precision

|

±1%

|

|

|

|

|

||||

|

Air system

|

Air compressor, etc

|

|

|

|

|

||||

|

Control system type

|

Computer auto-control module (PLC can be optional item)

|

|

|

|

|

||||

Related Suggestion

Features

1. Easy to transport, install and debug.

2. It has a variety of basic forms to ensure adaptability to different places.

3. The structural parts are durable.

4. The mixing system adopts JS (or SICOMA) two-axis strong concrete mixer, which has high efficiency and good mixing quality.

5. The computer control system plus PLC ensures simple and stable operation, and the dynamic panel display enables the operator to clearly understand the operation of each part. Abnormal working conditions and faults are easy to maintain and eliminate.

6. The main engine is cleaned by a high-pressure pump cleaning device, which has good maintenance performance.

Details Images

Hot Searches