Name:

Microcomputer

Brand:

Techmation/ARICO/KEBA

Original:

Germany /Taiwan

All international brand,we work with them more than 10 years.can according to customer using habit and manufacturing products requires to choose.

- Product Details

- {{item.text}}

Quick Details

-

Color:

-

green

-

Injection pressure:

-

2240cm2 - 1340cm2

-

Injection Rate:

-

28 34 47 cc/s

-

Injection Weight:

-

25 30 42 gr

-

Power(W):

-

5.5*2 Kw

Quick Details

-

Screw Speed (rpm):

-

0 - 180

-

Place of Origin:

-

Guangdong, China

-

Screw Diameter:

-

20mm - 55mm

-

Color:

-

green

-

Injection pressure:

-

2240cm2 - 1340cm2

-

Injection Rate:

-

28 34 47 cc/s

-

Injection Weight:

-

25 30 42 gr

-

Power(W):

-

5.5*2 Kw

Application

:

1.

TaiWang injection molding machine is suitable for multi-purpose injection molding.

2.

The following materials are suitable for our products:GPPS, HIPS, SAN, ABS,LDPE, HDPE,PP, PPO, PA6, PA66, ACEAL COPOLYMER, CAB, PET, PBT,PC, PMMA, hard PVC, soft PVC,PU, EVA, PSF, , BMC.

3.

TaiWang vertical injection machine are widely applied to produce various terminal blocks, household appliances, consumer electronics, power tools, automotive dashboards, medical devices, open containers, cables,auto parts, Plug ,etc.

4.

Overall, our vertical injection molding machines.Wide-range of materials such as plastic, rubber, silicone could be fromed according to your requirment and available to different industry like auto, electron, medical, living goods and shoe industry.

Multi-Color Machine Series

|

E-mail:jerry@twmachines.com. Phone/Whatsapp:+86-13829235050

|

|

|

|

|||

|

INJECTION UNIT

|

Item

|

Unit

|

TW-90VR-TC-2

|

|||

|

|

Screw Diameter

|

mm

|

26 30 32

|

|||

|

|

Injection Pressure

|

kgf/c㎡

|

2071 1555 1367

|

|||

|

|

Injection Capacity

|

cm³

|

63 84 96

|

|||

|

|

Injection Weight(P.S)

|

gr

|

57 76 86

|

|||

|

|

|

|

|

|||

|

|

Injection Rate

|

cc/s

|

52 70 80

|

|||

|

|

Screw Speed

|

r.p.m

|

0~220

|

|||

|

|

Screw Stroke

|

mm

|

120

|

|||

|

|

Heater

|

KW

|

4.1*2

|

|||

|

|

Drive Motor

|

KW

|

7.5*2

|

|||

|

CLAMPING UNIT

|

Clamping Force

|

tf

|

90(45*2)

|

|||

|

|

Min.Mould Height

|

mm

|

220

|

|||

|

|

Clamping Stroke

|

mm

|

250

|

|||

|

|

Max.Mould Space

|

mm

|

470

|

|||

|

|

Overall Size Of Platens(H×V)

|

mm

|

1050*440

|

|||

|

|

table Diamerer&Injection center

|

mm

|

Φ780/400

|

|||

|

|

Hydraulic Ejector Force

|

tf

|

2.6

|

|||

|

|

Ejector Stroke

|

mm

|

100

|

|||

|

OTHERS

|

Dimension of Machine(L×W×H)

|

m

|

1.4*1.7*3.5

|

|||

|

|

Weight Of Machine

|

t

|

6

|

|||

|

|

Oil Tank Capacity

|

L

|

320

|

|||

Intelligence control system

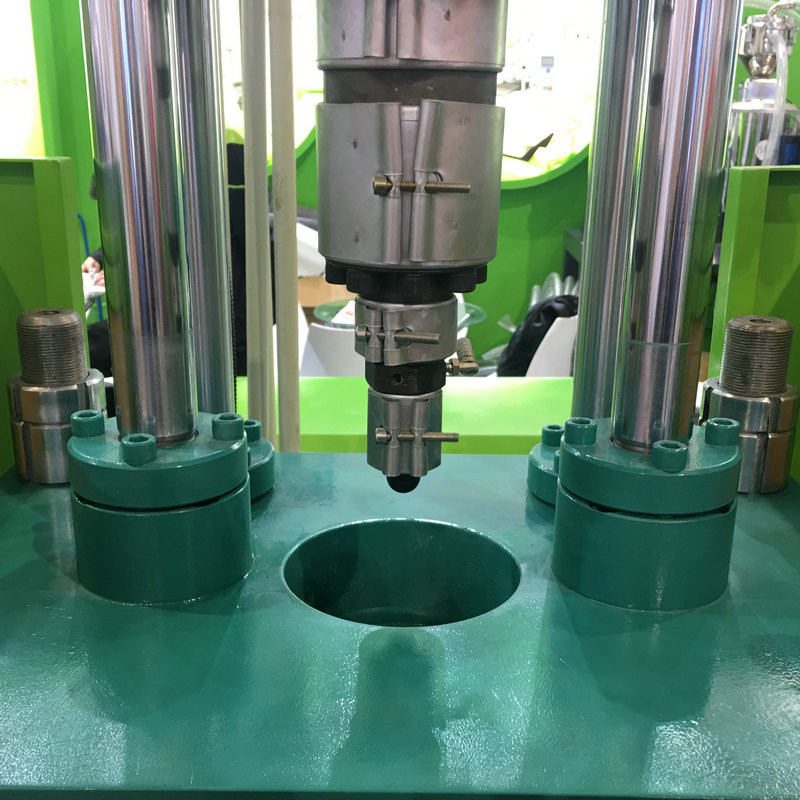

Name: Injection unit

Original:

Japan

♦ Quick response checking valve

♦ Dual alloy

39CrMoAl

screw and barrel

♦ High response and double cylinder injection system with automatic conversion function

♦ Screw back pressure

control

Large injection capacity

Name:

Screw

Material:

Alloy

Original:

TAIWAN

According to products,choose quality suitable screw

Name: Electric Unit

Original:

Japan

♦ Top brands electric parts supporting

♦ Euro standard safety standard

Name: Hydraulic unit

Original:

Japan

♦Top brands hydraulic parts ensure machine fast and stable

♦Visible and dischargeable oil tank, easy for hydraulic circuit maintenance

♦Top brand hydraulic pipe fits with seal, no leaking

♦High response hydraulic circuit,0.05S to reach the maximum power output

Company introduction:

Taiwang company have always prepared for plastic vertical injection moulding machine trading exhibition per year with excellent reputation in the worldwide market place for dependability.

1st step.

♦.Machine is surrounded by wrapping paper.

♦.Split the machine into two primary parts which decide to dimension of machine in the fixable wooden box.

2nd step.

♦.Grease the parts with antirust oil in order to avoid corrosion during transit.

♦.Fasten wooden box by nail and stick cautions.

3rd Step.

♦.Ship package to designated Port by crane.

♦.The professional supervises till package reach port smoothly.

Packaging Details: