- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JR

-

Product name:

-

High

-

Application:

-

Farm Work

-

Name:

-

coconut fiber extraction machine

-

Function:

-

Processing

-

Keywords:

-

coconut fiber extraction machine

-

After-sales Service Provided:

-

Engineers

-

Usage:

-

Agriculture Machiney Farm Equipments

-

Capacity:

-

Hour

-

Color:

-

Customer Required

-

Raw material:

-

Carbon Steel

Quick Details

-

Weight (KG):

-

250

-

Type:

-

coconut fiber

-

Use:

-

coconut fiber extraction machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JR

-

Product name:

-

High

-

Application:

-

Farm Work

-

Name:

-

coconut fiber extraction machine

-

Function:

-

Processing

-

Keywords:

-

coconut fiber extraction machine

-

After-sales Service Provided:

-

Engineers

-

Usage:

-

Agriculture Machiney Farm Equipments

-

Capacity:

-

Hour

-

Color:

-

Customer Required

-

Raw material:

-

Carbon Steel

Machine parameters

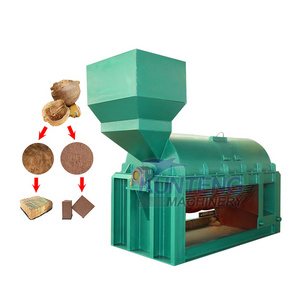

Coconut fiber extraction machine

Coconut fiber extracting machine is mainly to extracted the fibers in the coconut shell. Through the operation of the coconut silk machine, the coconut shell is crushed and deep-processed to produce a high-yield coconut fiber, which is packaged and stored forvarious uses.

It is a professional equipment that can break coconut shell, palm shell, bamboo, sugar cane and other materials into filamental materials and fiber extraction. Coconut cutting machine Large palm silk, coconut, palm and hemp fiber extraction machine, banana leaves crushing equipment

Working principle:

1. Raw materials enter the equipment through feeding inlet.

2. Crushing raw material by rapid rotation of the blade head inside machine.

3. Blade head rotates at high speed to stir and knead material into filaments, which discharged through outlet.

4. The leakage holes of the kneading box separate impurities and finished products effectively.

5. The finished products generally need to be screened by a bran sieve machine to further purify the finished materials.

1. Raw materials enter the equipment through feeding inlet.

2. Crushing raw material by rapid rotation of the blade head inside machine.

3. Blade head rotates at high speed to stir and knead material into filaments, which discharged through outlet.

4. The leakage holes of the kneading box separate impurities and finished products effectively.

5. The finished products generally need to be screened by a bran sieve machine to further purify the finished materials.

Product Paramenters

|

Machine model

|

JR-530

|

|

Voltage

|

110/220/380. Customizable single-phase or 3-phase

|

|

Material

|

Thickened 304 stainless steel&carbon steel

|

|

Applicable to

|

coconut

|

|

Size&Weight

|

1260*1270*900 215KG

|

|

Output

|

200-400KG/H

|

Details Images

Our services

1: Provide fast communication for customers

2: Provide customers with various solutions to do the biggest thing with the least amount of money

3. Any machine, provide an additional set of accessories for free

4. Provide the first free air freight service for damaged machine vulnerable parts in any country.

Adhere to timely service response, effective problem-solving, standardized service process, and comprehensive service content.

Delivery

Partial customer feedback

Transaction records

Customer Photos

Hot Searches