- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

GJ

-

Model Number:

-

DN4-40

-

Surface Treatment:

-

Rough surface

-

Product name:

-

FRP basalt rebar

-

Material:

-

Resin Fiberglass Composite

-

Feature:

-

Corrosion Resistance

-

Length:

-

Customized Length

-

Usage:

-

civil construction

-

Diameter:

-

DN4-40mm

-

Packing:

-

Bundle

-

OEM:

-

Availabe

-

Surface:

-

Sand Coating

-

Glass type:

-

E-glass or basalt

Quick Details

-

Application:

-

civil construction

-

Technique:

-

Pultrusion

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GJ

-

Model Number:

-

DN4-40

-

Surface Treatment:

-

Rough surface

-

Product name:

-

FRP basalt rebar

-

Material:

-

Resin Fiberglass Composite

-

Feature:

-

Corrosion Resistance

-

Length:

-

Customized Length

-

Usage:

-

civil construction

-

Diameter:

-

DN4-40mm

-

Packing:

-

Bundle

-

OEM:

-

Availabe

-

Surface:

-

Sand Coating

-

Glass type:

-

E-glass or basalt

Product Description

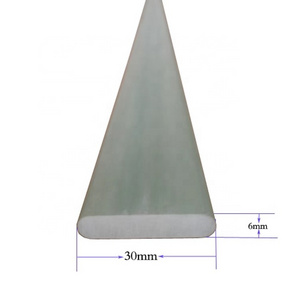

Specification

|

No.

|

Diameter (mm)

|

|

1

|

4

|

|

2

|

6

|

|

3

|

8

|

|

4

|

10

|

|

5

|

12

|

|

6

|

20

|

|

7

|

24

|

|

8

|

30

|

|

9

|

38

|

|

10

|

40

|

FRP( Short of Fiber Reinforced Plstic)

is one kind of composite material made through the composite process with polymer resin as the matrix such as E-glass/basalt fiber or carbon fiber as the reinforcement. It has the advantage of high tensile strength, low weight, corrosion resistance and non-conductive than the steel rebars.

Glassfiber reinforced polymer rebar (GFRP) is made from high technical performance resin (UP/VE/EP/PU)and glass fiber by pultrusion process.

Compared with steel rebars, GFRP Fiberglass Rebar/Basalt Fiber Rebar have many advantages:

1. High tensile strength.

-Its strength is approximately double of steel bar, And when you bend it, it will bounces back quickly, that make the building

more stable.

2. High corrosion resistance.

-Fiberglass rebar is waterproof and resistant to seawater corrosion, it never rust even stay in the concrete or building wall for many many years.

3. Low density and light weight.

-The meter weight is only 1/4 of steel bar, the worker can carry it easily, And also the transportation cost can be reduced much more.

4. Electrical insulation, without static electricity

-It has no electrical conductivity, and no sparks will be produced when being cut, it's particularly suitable for high risk gas

zones; like Coal mines, oil fields.

5. Easy Cutting.

-Easy to cut, very suitable for construction of tunnels and subway projects, It avoids damages to cutter heads and does not delay excavation.

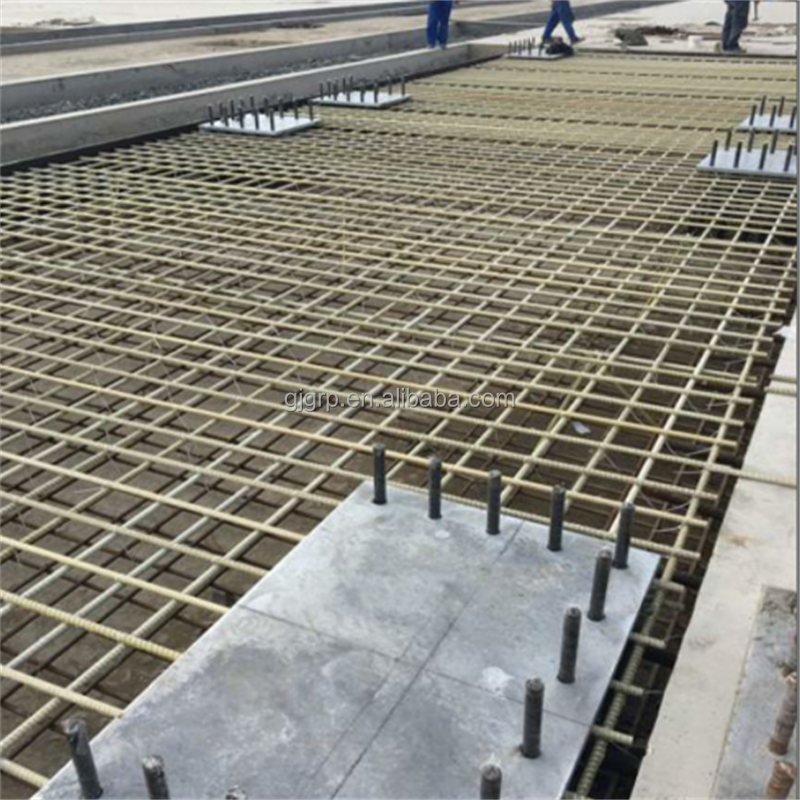

Applications:

Сonstruction,

subway tunnel,

coal mine tunnel,

rock surface anchoring,

sea wall,

parking structures,

slope support,

transportation industry and dam etc.

Glassfiber reinforced polymer rebar (GFRP) is made from high technical performance resin (UP/VE/EP/PU)and glass fiber by pultrusion process.

Compared with steel rebars, GFRP Fiberglass Rebar/Basalt Fiber Rebar have many advantages:

1. High tensile strength.

-Its strength is approximately double of steel bar, And when you bend it, it will bounces back quickly, that make the building

more stable.

2. High corrosion resistance.

-Fiberglass rebar is waterproof and resistant to seawater corrosion, it never rust even stay in the concrete or building wall for many many years.

3. Low density and light weight.

-The meter weight is only 1/4 of steel bar, the worker can carry it easily, And also the transportation cost can be reduced much more.

4. Electrical insulation, without static electricity

-It has no electrical conductivity, and no sparks will be produced when being cut, it's particularly suitable for high risk gas

zones; like Coal mines, oil fields.

5. Easy Cutting.

-Easy to cut, very suitable for construction of tunnels and subway projects, It avoids damages to cutter heads and does not delay excavation.

Applications:

Сonstruction,

subway tunnel,

coal mine tunnel,

rock surface anchoring,

sea wall,

parking structures,

slope support,

transportation industry and dam etc.

Packing & Delivery

Hot Searches