- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhengzhou Jiude Machinery

-

Dimension(L*W*H):

-

Defined by model

-

Nominal Pressure (kN):

-

16000

-

Briquette Size (mm):

-

80

-

Briquette Thickness (mm):

-

60-80

-

Density (t/m3):

-

5

-

Briquette Weight (kg):

-

2.5-3

-

Production Cycle (Round/min):

-

3-5

-

Production Rate (t/h):

-

0.4-0.8

-

Power (kW):

-

24-39

-

Machine Weight (kg):

-

7500

-

Dimensions (mm):

-

4100*1080*2000

Quick Details

-

Weight (KG):

-

7500

-

Marketing Type:

-

New Product 2023

-

Production Capacity:

-

1-3 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhengzhou Jiude Machinery

-

Dimension(L*W*H):

-

Defined by model

-

Nominal Pressure (kN):

-

16000

-

Briquette Size (mm):

-

80

-

Briquette Thickness (mm):

-

60-80

-

Density (t/m3):

-

5

-

Briquette Weight (kg):

-

2.5-3

-

Production Cycle (Round/min):

-

3-5

-

Production Rate (t/h):

-

0.4-0.8

-

Power (kW):

-

24-39

-

Machine Weight (kg):

-

7500

-

Dimensions (mm):

-

4100*1080*2000

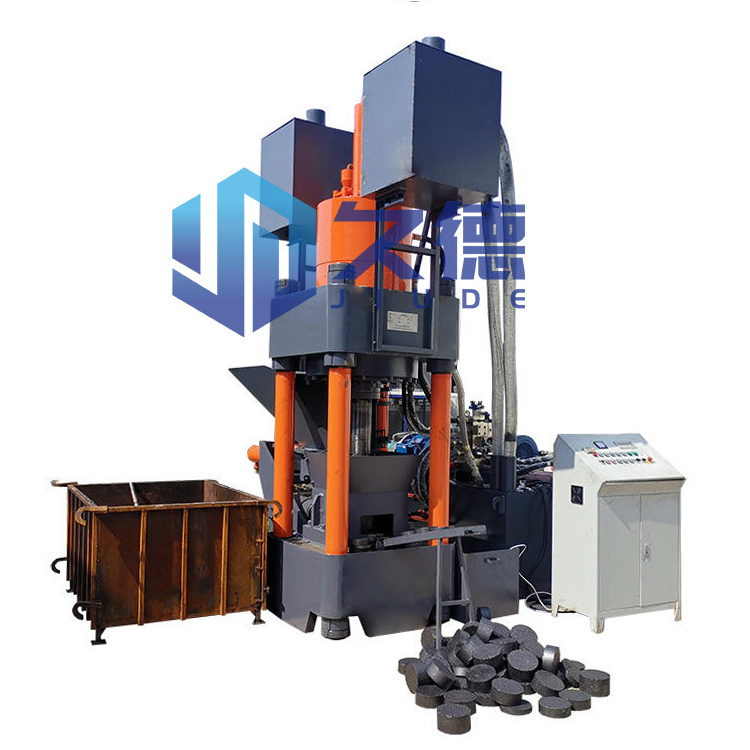

Machine Description

This equipment can cold press the powdered and granular cast iron filings, steel filings, copper filings, aluminum filings, etc. directly into 3~6kg cylindrical briquettes for transportation, furnace throwing, and the whole process without heating-up, additives, or other processes. The density of cast iron filings can reach 5~6t/m3 after pressing.

The product can also adopt domestic or imported hydraulic and electrical components according to customers' requirements, with automatic feeding and weighing devices.

Applications

It is specially designed for the recycling and reuse of iron filings, aluminum filings, steel filings and cast iron filings produced in aluminum alloy profile factory, steel casting factory, aluminum casting factory, copper casting factory, automobile,

motorcycle manufacturing and parts, railroad machinery, moulds, valves, aluminum products, electronics, new materials, aluminum profiles and other industries.

motorcycle manufacturing and parts, railroad machinery, moulds, valves, aluminum products, electronics, new materials, aluminum profiles and other industries.

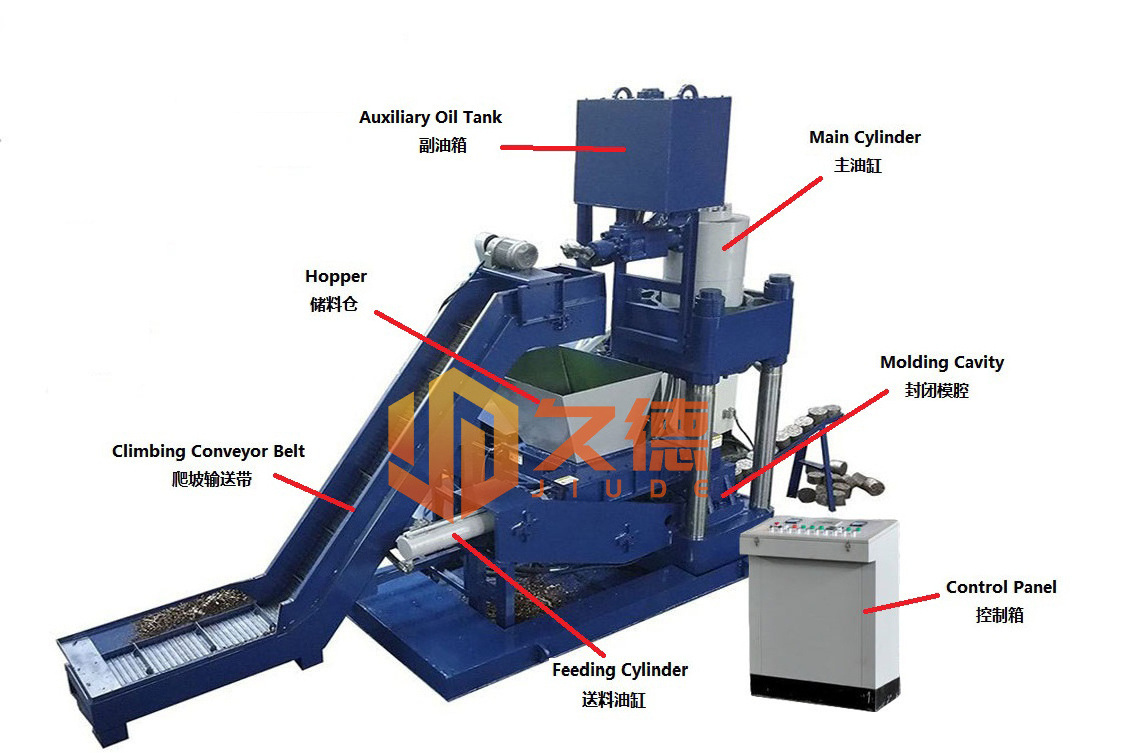

Product structure

The metal chip briquetting machine equipment is composed of main machine, feeding device, hydraulic pump station and control cabinet, as follows:

① Mainframe: It is composed of frame, main hydraulic cylinder, bottom hydraulic cylinder, supporting mold frame and mold, press head and so on. The main hydraulic cylinder is made of 45# steel, without cast steel parts and welded parts. Eliminate safety hazards, to ensure the reliability, service life and safety of the equipment. Matching die frame and die, pressure head, etc. are made of alloy wear-resistant gold steel, designed with superior processing ability is the guarantee of excellent taste of the equipment. The dies and punches are equipped with quick-changeable dies and punches, and the front end of the punches is equipped with pressure rings for easy removal and installation, thus prolonging their service life. The relevant parts are specially hardened or forged in the necessary parts.

② Feeding device: It consists of reducer, feeding auger, etc.

The reducer adopts high efficiency reducer, with efficiency of 96%, low vibration, low noise and superior performance. The auger adopts alloy wear-resistant gold steel with special hardening treatment. It has good rigidity, high wear resistance and long service life.

③ Hydraulic station: It consists of motor, hydraulic pump, pump protection device, control valve block and connecting pressure block

Machine features

1) Seamless alloy tube for the oil cylinder, fine-turning and grinding, durable use

2) Super high-pressure steel wire rubber pipe, easy to connect, safe and stable

3) The upper and lower beams are made of integral castings, with good stability

4) The column adopts high quality #45 round steel heat treatment, high rigidity and toughness

5) Axial piston pump, smooth operation, uniform flow, low noise

6) Large diameter valve set, smooth operation

7) Adjustable oil pressure size

8) Standard heat exchanger to prevent oil overheating and ensure continuous production

9) Spiral forced feeding, solve the fluffy material

10) No material in the mold box with automatic stop function

11) PLC and human-machine interface control system or relay control system; users can choose manual or automatic operation

12) Oil recovery to avoid pollution of the environment

13) All oil cylinders are equipped with photoelectric switch control to avoid cylinder shock, safe and reliable

14) Provide complete machine learning and operation information

Machine Parameters

|

Model

|

Nomnal

Pressure

(KN)

|

Briquette

Size(mm)

|

Briquette

Thickness

(mm)

|

Density

(t/m)

|

Briquette

Weight

(kg)

|

Production

Cycle

(Round/min)

|

Production

Rate

(t/h)

|

|

Y83-1600A

|

1600

|

80

|

60-80

|

25

|

2-2.5

|

3

|

0.25-0.3

|

|

Y83-1600B

|

1600

|

80

|

60-80

|

25

|

2-2.5

|

3

|

0.25-0.3

|

|

Y83-2000A

|

2000

|

80

|

60-80

|

25

|

2.5-3

|

4

|

0.4-0.6

|

|

Y83-2000B

|

2000

|

80

|

60-80

|

25

|

2.5-3

|

5

|

0.5-0.75

|

|

Y83-2000C

|

2000

|

80

|

60-80

|

25

|

2.5-3

|

6

|

0.5-0.8

|

|

Y83-2500A

|

2500

|

80-90

|

60-80

|

25.2

|

2.5-3.5

|

5

|

0.6-0.8

|

|

Y83-2500B

|

2500

|

80-90

|

70-80

|

≥5.2

|

2.5-3.5

|

5

|

0.6-0.8

|

|

Y83-2500C

|

2500

|

80-90

|

60-80

|

25.2

|

2.5-3.5

|

5

|

0.6-0.8

|

|

Y83-3150A

|

3150

|

90-110

|

60-80

|

£5.5

|

3-4

|

6

|

1-1.2

|

|

Y83-3600

|

3600

|

100-120

|

60-80

|

25.5-6

|

4-5

|

5

|

1.2-1.5

|

|

Y83-5000

|

5000

|

120-140

|

60-80

|

25.5-6

|

5-8

|

4.5

|

1.5-2

|

|

Y83-6300

|

6300

|

150-200

|

100-120

|

25.5-6

|

8-1.2

|

4

|

2-2.5

|

Packing & Shipping

Customer Cases

About US

Zhengzhou Jiude Machinery Manufacturing Co., LTD is a company founded in 2017 that focuses on designing and developing hydraulic equipment for metal、non-metal and wood recycling industry.

We have a global presence served thousands of equipment. With a dedicated professional team, we continuously research and develop new products, improve manufacturing technology, and cater to customer requirements and industry trends.

Hot Searches