Low Melting Point, Good Activity, High Insulation Resistance. High soldering speed can help to reduce the thermal shock to the

components and lower operator's soldering time.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

100g, 200g, 250g, 500g, 1000g

-

Flux Content:

-

1.8% to2.2%

-

Warranty:

-

1year

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Tin Lead Solder wire

-

Application:

-

PCB Repairing, electronics welding, led lighting

-

Product name:

-

Tin Lead Solder wire

Quick Details

-

Material:

-

Tin Lead

-

Diameter:

-

0.5-3.0mm

-

Melting Point:

-

227(℃)

-

Weight:

-

100g, 200g, 250g, 500g, 1000g

-

Flux Content:

-

1.8% to2.2%

-

Warranty:

-

1year

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Tin Lead Solder wire

-

Application:

-

PCB Repairing, electronics welding, led lighting

-

Product name:

-

Tin Lead Solder wire

Product Description

|

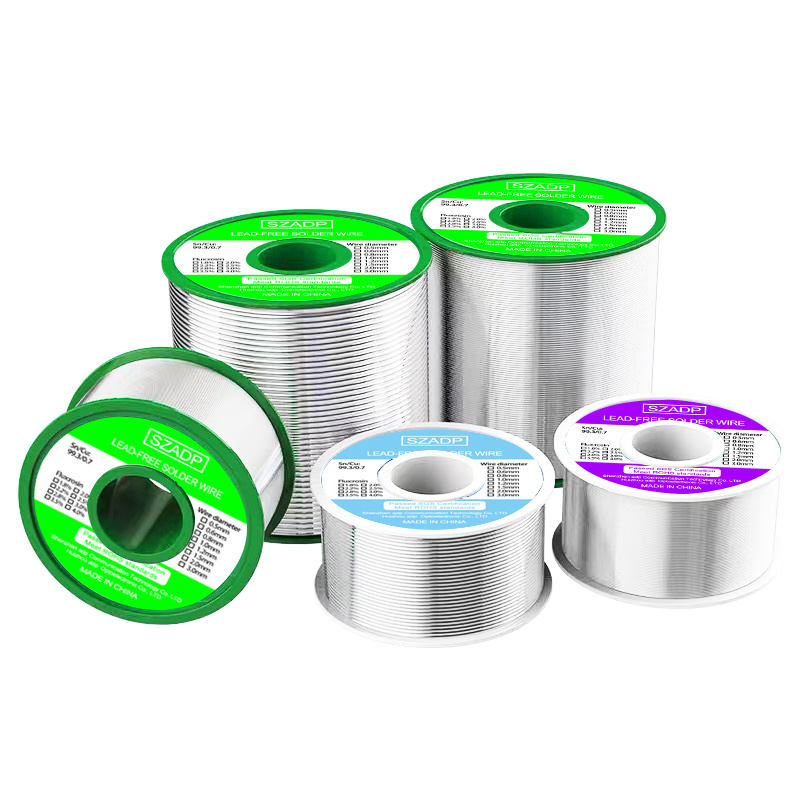

LEAD SOLDER WIRE

|

|

|

|

|

||||

|

ITEM.NO.

|

MATERIAL

|

DIAMETER(MM)

|

WEIGHT/ROLL

|

MELTING POINT

|

||||

|

63%

|

Sn63%, Pb37%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/500g/1kg

|

183℃

|

||||

|

60%

|

Sn60%, Pb40%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/500g/1kg

|

183℃ - 190℃

|

||||

|

63%

|

Sn55%, Pb45%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/500g/1kg

|

183℃ - 203℃

|

||||

|

1#

|

Sn50%, Pb50%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/500g/1kg

|

183℃ - 215℃

|

||||

|

2#

|

Sn45%, Pb55%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/500g/1kg

|

183℃ - 221℃

|

||||

|

3#

|

Sn40%, Pb60%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/500g/1kg

|

183℃ - 235℃

|

||||

|

4#

|

Sn35%, Pb65%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/500g/1kg

|

183℃ - 245℃

|

||||

|

5#

|

Sn30%, Pb70%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/500g/1kg

|

183℃ - 255℃

|

||||

|

6#

|

Sn25%, Pb75%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/500g/1kg

|

183℃ - 267℃

|

||||

|

7#

|

Sn20%, Pb80%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/500g/1kg

|

183℃ - 279℃

|

||||

|

LEAD-FREE SOLDER WIRE

|

|

|

|

|

||||

|

ITEM.NO.

|

MATERIAL

|

DIAMETER(MM)

|

WEIGHT/ROLL

|

MELTING POINT

|

||||

|

Sn-0.7Cu

|

Sn99.3%, Cu0.7%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/1kg

|

227℃ - 277℃

|

||||

|

Sn100

|

Sn100%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/1kg

|

217℃ - 277℃

|

||||

|

Sn0.3AgCu

|

Sn99.7%, (Cu+Ag)0.3%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/1kg

|

217℃ - 277℃

|

||||

|

Sn3AgCu

|

Sn97%, (Cu+Ag)3%

|

0.6/0.8/1/1.2/1.5/2

|

10g/50g/75g/450g/1kg

|

217℃ - 277℃

|

||||

Product Features:

1. Favorable Fatigue Resistance and Outstanding Soldering Performance

2. Ultra High Electrical Conductivity

3. Mid-Temperature Soldering

The manufactured product belongs to the mid-temperature solder, which is characterized by nice softness, and wonderful wetting property.

4. Benefits from Activated Rosin Flux

The solder bar is doped with an appropriate amount of activated rosin flux, thus providing distinguished soldering effect, fast soldering speed, as well as extremely good fluidness.

5. Ultra Strong Oxidation Resistance

Due to the addition of anti-oxidant element, our Sn60Pb40 no-clean tin lead solder wire and solder bar can give strong resistance to oxidation. The mid-temperature solder is difficult to be softened, and its anti-oxidant capacity is greatly enhanced.

2. Ultra High Electrical Conductivity

3. Mid-Temperature Soldering

The manufactured product belongs to the mid-temperature solder, which is characterized by nice softness, and wonderful wetting property.

4. Benefits from Activated Rosin Flux

The solder bar is doped with an appropriate amount of activated rosin flux, thus providing distinguished soldering effect, fast soldering speed, as well as extremely good fluidness.

5. Ultra Strong Oxidation Resistance

Due to the addition of anti-oxidant element, our Sn60Pb40 no-clean tin lead solder wire and solder bar can give strong resistance to oxidation. The mid-temperature solder is difficult to be softened, and its anti-oxidant capacity is greatly enhanced.

Sophisticated Technology

Fresh Raw Materials

By using high purity Tin ingot materials + electrolytic lead and special process. Our Solder Wire can keep high soldering speed,

less residue, good wettability, excellent thermal and electrical conductivity.

less residue, good wettability, excellent thermal and electrical conductivity.

Products Show

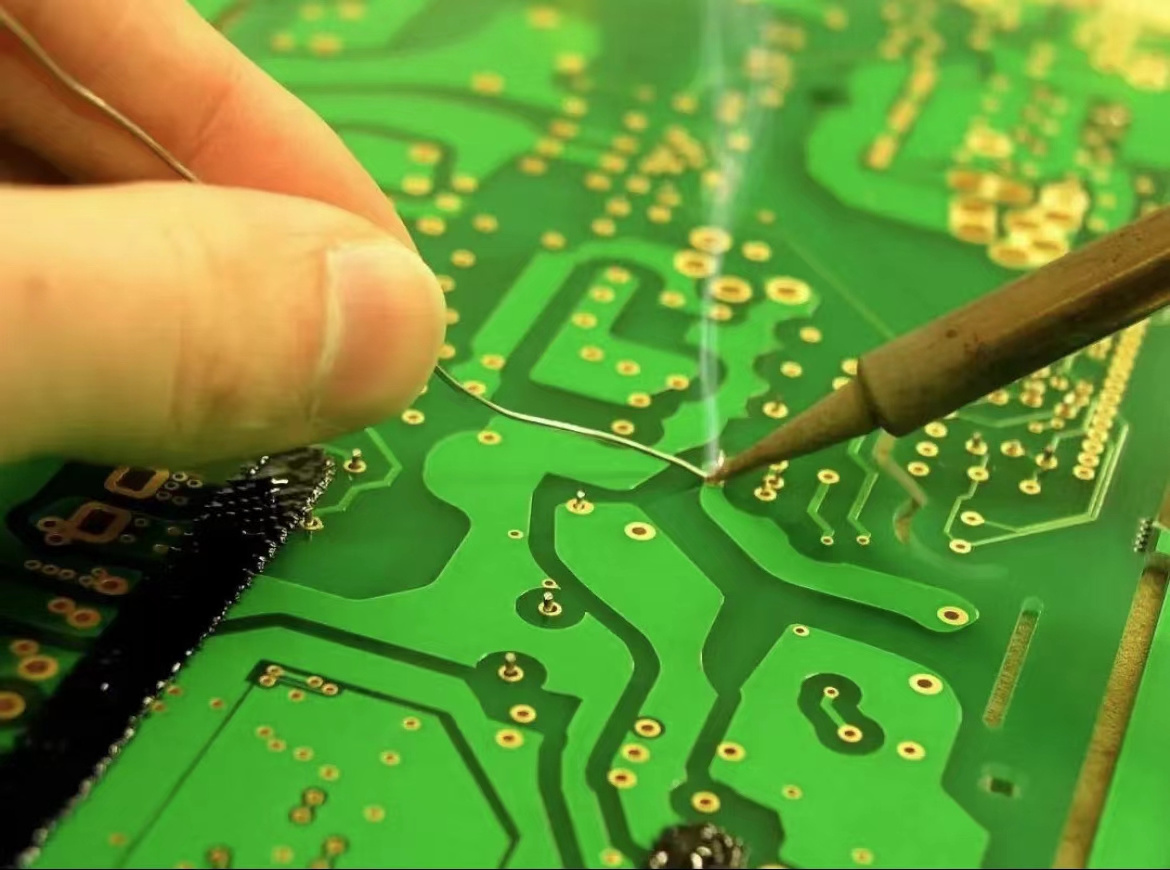

Application

Used for welding of electronic products, circuit boards, LED, microelectronics, computers, household appliances and other products,PCB Repairing.

Hot Searches