- Product Details

- {{item.text}}

Quick Details

-

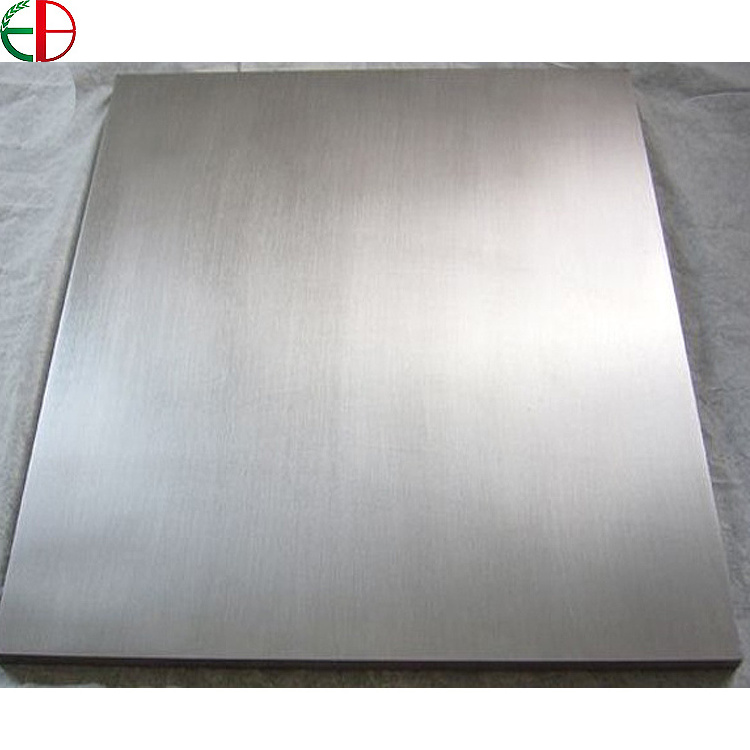

Model Number:

-

EB9908

-

Shape:

-

Sheet

-

Material:

-

Tantalum, Ta1/Ta2

-

Chemical Composition:

-

99.95%min

-

Density:

-

16.69 g/cm3

-

Melting Point:

-

3017 Degree Celsius

-

Boiling Point:

-

5458 Degree Celsius

-

Appearance:

-

Silvery-gray Solid

-

Electrical Resistivity:

-

131

-

Electronegativity:

-

1.5 Paulings

Quick Details

-

Application:

-

High Temperature,Industrial, Electronic, Medical

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

EB

-

Model Number:

-

EB9908

-

Shape:

-

Sheet

-

Material:

-

Tantalum, Ta1/Ta2

-

Chemical Composition:

-

99.95%min

-

Density:

-

16.69 g/cm3

-

Melting Point:

-

3017 Degree Celsius

-

Boiling Point:

-

5458 Degree Celsius

-

Appearance:

-

Silvery-gray Solid

-

Electrical Resistivity:

-

131

-

Electronegativity:

-

1.5 Paulings

Product Description

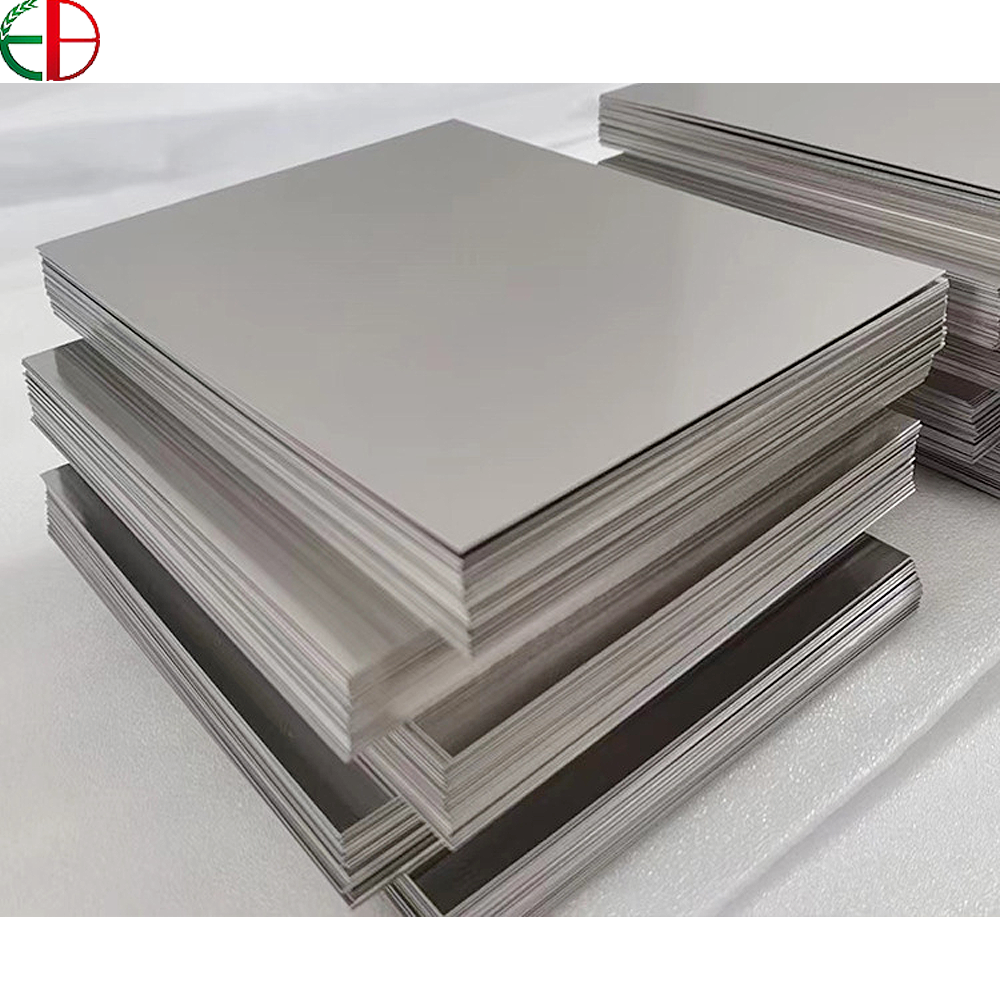

EB China specializes in producing Tantalum as rolled sheets in various thicknesses and sizes. Most sheets are produced from cast ingots for use in coating and thin film Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) processes including Thermal and Electron Beam (E-Beam) Evaporation, Low Temperature Organic Evaporation, Atomic Layer Deposition (ALD), Organometallic and Chemical Vapor Deposition (MOCVD) for specific applications such as fuel cells and solar energy. Thickness can range from 0.04" to 0.25" for all metals. Materials are produced using crystallization, solid state and other ultra high purification processes such as sublimation.

EB China specializes in producing custom compositions for commercial and research applications and for new proprietary technologies. American Elements also casts any of the rare earth metals and most other advanced materials into rod, bar, or plate form, as well as other machined shapes and through other processes such as nanoparticles and in the form of solutions and organometallics. We also produce Tantalum as rods, powder and plates. Other shapes are available by request.

Tantalum plates are used in a wide range of industries. In each of these applications, the tantalum has certain properties that are more critical than others. That is why it is essential to work with an experienced and reputable tantalum supplier who can understand your application. Our team has well over 50 years of experience working with tantalum in applications ranging from missile parts to microchips. Because of this experience, Admat has developed unique production processes in which we can control certain properties such as mechanical properties, grain size, texture, and even chemistry.

Our high purity sputtering plates are a perfect example in which we manage the grain size, texture, and chemistry. It’s been shown that uniform grain size and certain blends of grain orientation (texture) help to produce a better performing sputtering target during manufacturing. And the purities from 99.95% to 99.999% improve the tantalum’s performance in the final product.

Our high purity sputtering plates are a perfect example in which we manage the grain size, texture, and chemistry. It’s been shown that uniform grain size and certain blends of grain orientation (texture) help to produce a better performing sputtering target during manufacturing. And the purities from 99.95% to 99.999% improve the tantalum’s performance in the final product.

Our Tantalum plate is sold for use in a wide variety of industries including:

Our tantalum 2.5% tungsten plates are designed to survive in corrosive environments, while our tantalum 10% tungsten alloy is designed for high-temperature corrosive environments. We also have furnace-grade tantalum that has small amounts of additives to slow grain growth and improve life in vacuum furnaces.

*Semiconductor and electronics

*Defense

*Furnace parts

*Chemical processing equipment

*Medical

Thickness Maximum Width:

.100″ and up 39″ (other sizes may be available with engineering review)

|

Product Name

|

Tantalum Sheet

|

|

|

|

|||

|

Purity

|

99.95%Min

|

|

|

|

|||

|

Grade

|

R05200,R05400,R05255,R05252,R05240

|

|

|

|

|||

|

Standard

|

ASTM B708,GB/T 3629

|

|

|

|

|||

|

|

Item

|

Thickness(mm)

|

Width(mm)

|

Length(mm)

|

|||

|

|

Foil

|

0.01-0.09

|

30-150

|

>200

|

|||

|

|

Sheet

|

0.1-0.5

|

30-609.6

|

30-1000

|

|||

|

|

Plate

|

0.5-10

|

20-1000

|

50-2000

|

|||

|

|

1.Hot-rolled/Cold-rolled;

2.Alkaline Cleaning;

3.Electrolytic polish;

4. Machining,Grinding;

5.Stress relif annealing;

|

|

|

|

|||

|

Mechanical Property

|

Grade(UNS)

|

Tensile strength min

|

Yeild strength min

|

Elongation min,%

|

|||

|

(annealed)

|

|

Psi (Mpa)

|

psi(Mpa)(2%)

|

(1inch gage length)

|

|||

|

|

Pure Ta(R05200,R05400)

|

30000(207)

|

20000(138)

|

20

|

|||

|

|

Ta-10W(R05255)

|

70000(482)

|

60000(414)

|

15

|

|||

|

|

Ta-2.5W(R05252)

|

40000(276)

|

30000(207)

|

20

|

|||

|

|

Ta-40Nb(R05240)

|

35000(241)

|

20000(138)

|

25

|

|||

|

Sheet & Plate Specifications

|

|

|

|

|

||||

|

Available Sizes for Tantalum Sheet & Plate

|

|

|

|

|

||||

|

Thickness

|

Maximum Width

|

Common Specifications

|

Available Alloys

|

Available Purities:

|

||||

|

.001″

|

6″

|

ASTM B708 R05200

|

Tantalum

|

Commercial Grade ( ASTM )

|

||||

|

.002” to .009”

|

12″

|

» Electron Beam Melted (Unalloyed)

|

Tantalum 2.5% Tungsten

|

3N 99.90% | 3N5 99.95%

|

||||

|

.010″ to .090″

|

25″

|

ASTM B708 R05400

|

Tantalum 7.5% Tungsten

|

4N 99.99% | 4N5 99.995%

|

||||

|

.100″ and up

|

39″

|

» Powder Metallurgy Grade (Unalloyed)

|

Tantalum 10% Tungsten

|

5N 99.999%

|

||||

|

|

|

ASTM B708 R05252

|

Tantalum 40% Niobium

|

|

||||

|

|

|

» Tantalum 2.5% Tungsten Alloy

|

Furnace Grade Tantalum

|

|

||||

|

|

|

ASTM B708 R0255

|

|

|

||||

|

|

|

» Tantalum 10% Tungsten Alloy

|

|

|

||||

|

|

|

AMS 7849 Rev E

|

|

|

||||

|

|

|

» Electron Beam Melted

|

|

|

||||

Feature:

1. Good ductility

2. Good plasticity

3. Excellent acid-resistance

4. High melting point, high boiling point

5. Very small coefficients of thermal expansion

6. Good capability of absorbing and releasing hydrogen

Application:

1.Electronic Instrument

2.Industry Steel industry

3.Chemical industry

4.Atomic energy industry

5.Aerospace aviation

6.Cemented carbide

7.Medical treatment

Why Choose Us

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5~10 days if the goods are in stock.Or it is 45 days if the goods are not in stock, it is according to

quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shipment. irrevocable LC at sight.

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5~10 days if the goods are in stock.Or it is 45 days if the goods are not in stock, it is according to

quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shipment. irrevocable LC at sight.

Hot Searches