The use of V

ulcanized tyre label

:

1.

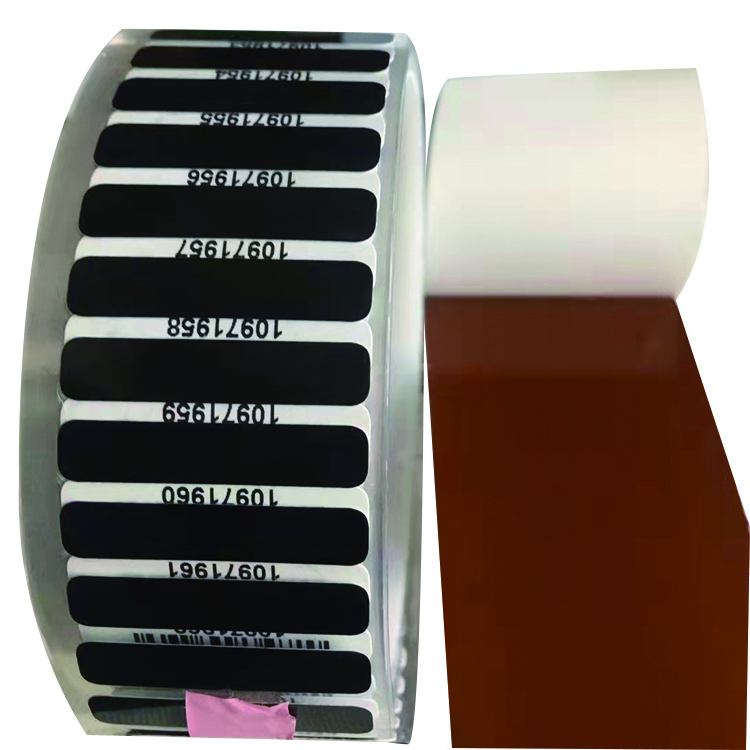

Use barcode label as data carrier.

2.

Keep the original iron plates (tire plates).

3.

Stick the bar code label and iron label together.

4.

Bar code data is the same as iron tire number data.

5.

After the tire is pressed down, the front side of the iron plate (protruding part) and tread contact, constitute data indentation,the reverse side of the label and tread contact, adhere to the tire.

6.

The use of tags and iron tags matching, even if the label is destroyed, can also be tracked according to the tire number of iron tags.

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

PET

-

Brand Name:

-

OwnLikes

-

Model Number:

-

LH0012

-

Place of Origin:

-

Guangdong, China

-

Industrial Use:

-

Car manufacturer

-

Size:

-

Customized Size

-

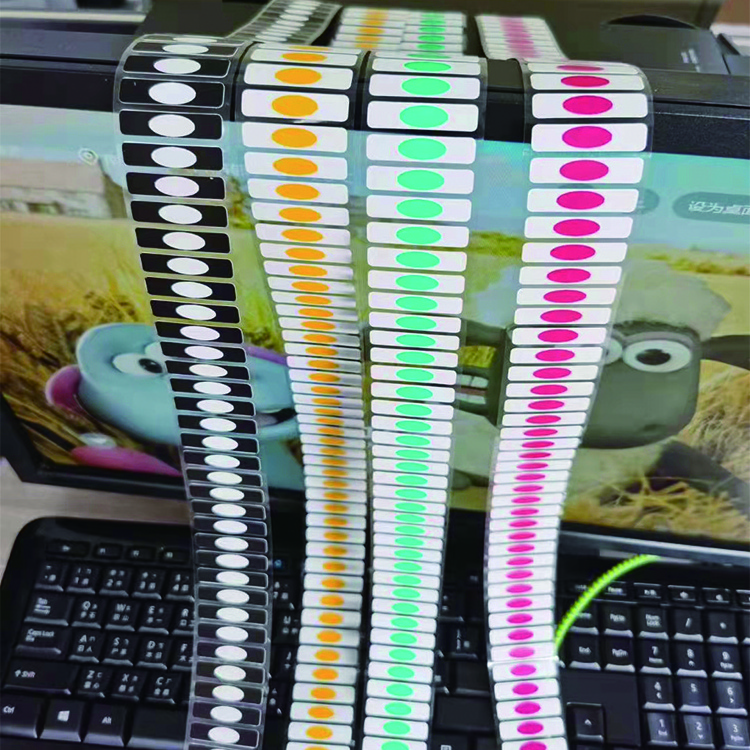

Color:

-

Hot stamping stickers

-

Application:

-

Wine packaging

-

Shape:

-

Custom Shapes

-

Printing:

-

PS Plate Printing+Hot stamping

-

Product name:

-

Hot stamping stickers

-

Keywords:

-

Custom tyre barcode label

-

Logo:

-

Customer's Logo

-

Name:

-

vulcanized tyre label

-

Item:

-

Custom Printed

Quick Details

-

Use:

-

Custom Sticker

-

Type:

-

Adhesive Sticker

-

Feature:

-

Barcode

-

Material:

-

PET

-

Brand Name:

-

OwnLikes

-

Model Number:

-

LH0012

-

Place of Origin:

-

Guangdong, China

-

Industrial Use:

-

Car manufacturer

-

Size:

-

Customized Size

-

Color:

-

Hot stamping stickers

-

Application:

-

Wine packaging

-

Shape:

-

Custom Shapes

-

Printing:

-

PS Plate Printing+Hot stamping

-

Product name:

-

Hot stamping stickers

-

Keywords:

-

Custom tyre barcode label

-

Logo:

-

Customer's Logo

-

Name:

-

vulcanized tyre label

-

Item:

-

Custom Printed

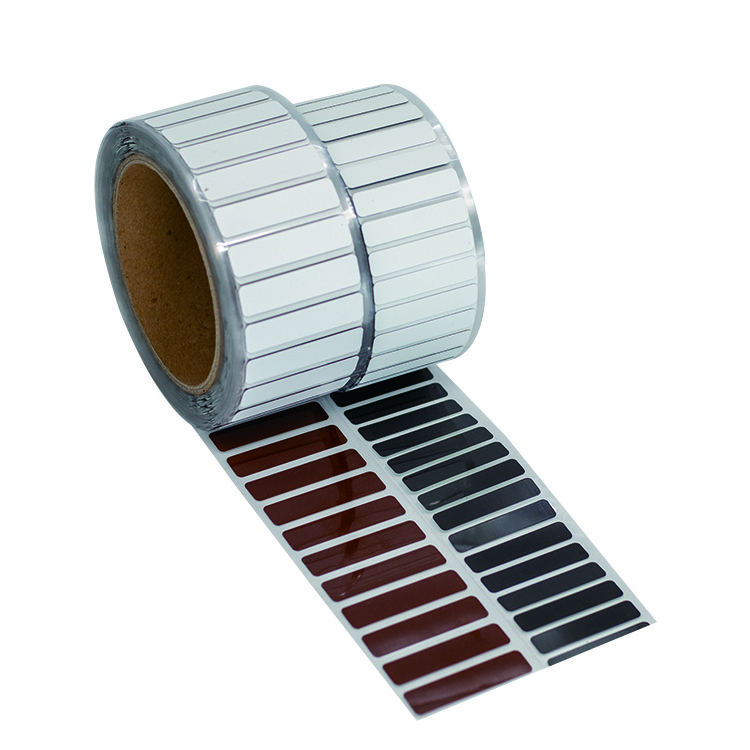

V

ulcanized tyre label

is a white polyester film, mostly used in the field of tire labels. Specially designed for pre-vulcanization applications, operating temperatures up to 210 ° C, but must be tested by the end user.

This material can effectively prevent water, acid, salt, alkali, most petroleum oil stains and low fat solvents. It is suitable for sticking tires under high temperature of vulcanization.

Products Description

|

Surface Substrate

(EPDM Polyester base)

|

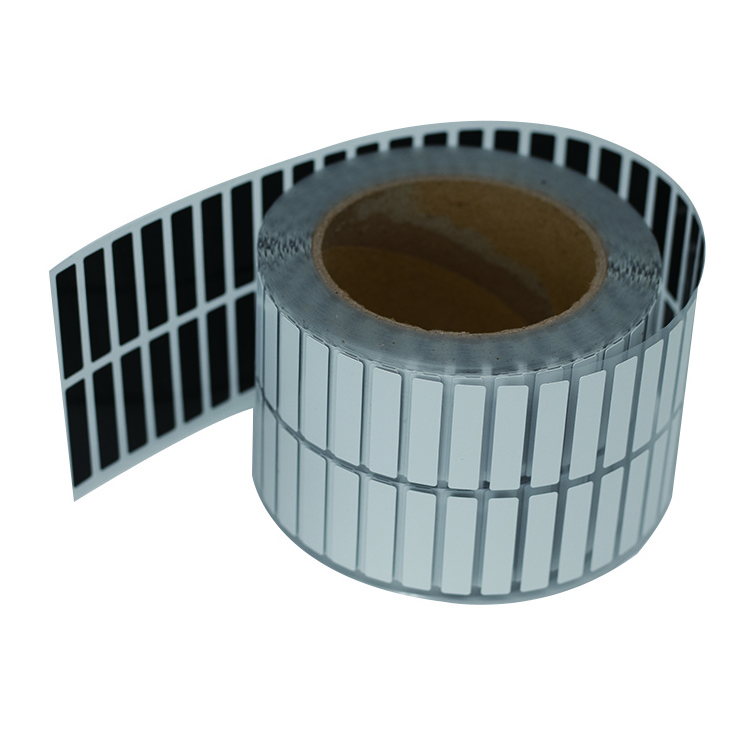

0.1mm thickness is suitable for the traceability of motorcycle tires, battery car tires and bicycle tires.

|

|

|

0.15mm thickness is suitable for the traceability of car tires and automobile tires.

|

|

|

0.188mm thickness is suitable for the traceability of rubber products such as rubber pipes and rubber sheets.

|

|

|

0.25mm thickness is suitable for the traceability of tires for large vehicles such as engineering vehicles and buses.

|

|

|

0.25mm thickness is suitable for the traceability of tires of large vehicles such as buses and passenger cars.

|

|

|

0.5mm thickness is suitable for the traceability of tires for large vehicles such as engineering vehicles and buses.

|

|

Release Paper

(Transparent polyester release film)

|

Weight: 80g/m2

|

|

|

Thickness: 50 microns

|

|

|

Tensile Force: Machine direction 405N/ 25mm, Transverse 405N/ 25mm

|

|

|

Tear Resistance: 140g in Machine direction

|

|

Adhesive

|

OwnLikes Self-made silicone rubber solvent-based adhesive

|

|

|

Weight: 50g/m2

|

|

|

Thickness: 40 microns

|

|

|

Minimum labeling temperature: 0 ℃

|

|

|

Operating temperature range: 0 ℃ ~210 ℃

|

|

Print Method

|

Heat transfer printing, digital laser engraving

|

|

Curing Time

|

Thickness ≤0.15mm,130℃ vulcanization for 60 minutes

|

|

|

Thickness ≥0.188mm,130℃ vulcanization for 180 minutes

|

|

Printing & Processing

|

Suitable for UV ink printing or heat transfer ribbon printing;

It is recommended to use B110CR, DNP-300 and other resin ribbon printing;

For die-cutting requirements, please refer to the technical guide.

|

|

Store Temperature

|

-5℃-22℃

|

|

Store Humidity

|

Relative HUmidity 50%(12 monthes)

|

|

Size

|

Thickness

|

R(mm)

|

Quan(Roll)

|

Roll Core

|

Application

|

||||

|

15mm*15mm

|

150uum

|

R1

|

10000

|

76mm

|

Motorcycle tire

Battery car tire

Bicycle tire

Car tire

OPDM pipe

And other rubber products

|

||||

|

20mm*20mm

|

150uum

|

R1

|

10000

|

76mm

|

|

||||

|

30mm*30mm

|

150uum

|

R2

|

5000

|

76mm

|

|

||||

|

30mm*6mm

|

150uum

|

R1

|

10000

|

76mm

|

|

||||

|

30mm*6mm

|

150uum

|

R1

|

10000

|

76mm

|

|

||||

|

30mm*8mm

|

150uum

|

R1

|

10000

|

76mm

|

|

||||

|

32mm*6mm

|

150uum

|

R1

|

10000

|

76mm

|

|

||||

|

32mm*8mm

|

150uum

|

R1

|

10000

|

76mm

|

|

||||

|

38mm*8mm

|

150uum

|

R1

|

10000

|

76mm

|

|

||||

|

35mm*11mm

|

150uum

|

R2

|

5000

|

76mm

|

|

||||

|

44mm*8mm

|

250um

|

R2

|

5000

|

76mm

|

Engineering car tire

Bus tire

Large automobile tire

Rubber pipe

Rubber sheet

And other EPMD rubber products

|

||||

|

44mm*12mm

|

250um

|

R2

|

5000

|

76mm

|

|

||||

|

48mm*15mm

|

250um

|

R2

|

5000

|

76mm

|

|

||||

|

50mm*12mm

|

250um

|

R2

|

5000

|

76mm

|

|

||||

|

50mm*15mm

|

250um

|

R2

|

5000

|

76mm

|

|

||||

|

54mmn*16mm

|

250um

|

R2

|

5000

|

76mm

|

|

||||

|

70mm*16mm

|

250um

|

R2

|

5000

|

76mm

|

|

||||

|

Custom size

|

Vulcanized label thickness optional: 0.1mm/0.15mm/0.2mm/0.25mm/0.3mm/0.35mm/0.5mm

|

|

|

|

|

||||

Our Advantages

but also can have good resistance of lotion,oil,igh pressure cleaning and friction.

Thickness ≤0.15mm,130℃ vulcanization for 60 minutes.

Thickness ≥0.188mm,130℃ vulcanization for 180 minutes.

Thickness ≥0.250mm,130℃ vulcanization for 360 minutes.

Good printing clarity, can batch print barcode serial number.

It is suitable for sticking tires under high temperature of vulcanization.

Application

How To Inspect & Control

Quality is our culture and first thing:

OwnLikes super focused on quality control and product testing.Here we will show you our inspection flow for your reference and make you rest assured to place order to OwnLikes team.

From raw material,then to machine,then the first article inspetion,then routing inspection ducing production,then last article inspection,then post treatment,then final inspetion and package.We will have professional inspection team to do inspection each step.

About OwnLikes

Hot Searches