- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2024

-

Weight (KG):

-

1100 KG

-

Power (kW):

-

24kw

-

Name:

-

Wood Sawdust Making Pallet Foot Block Machine

-

Model:

-

BD-HP80*80

-

Type:

-

Hot Pressing

-

Capacity:

-

3-4m³/24h

-

Usage:

-

Making Wood Pallet

-

Raw material:

-

Wood Sawdust

-

Color:

-

Customers' Demand

-

Voltage:

-

12kw

-

Certification::

-

CE Certification

-

Advantages:

-

High efficiency

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BEDO

-

Machine Type:

-

Hot press

-

Marketing Type:

-

New Product 2024

-

Weight (KG):

-

1100 KG

-

Power (kW):

-

24kw

-

Name:

-

Wood Sawdust Making Pallet Foot Block Machine

-

Model:

-

BD-HP80*80

-

Type:

-

Hot Pressing

-

Capacity:

-

3-4m³/24h

-

Usage:

-

Making Wood Pallet

-

Raw material:

-

Wood Sawdust

-

Color:

-

Customers' Demand

-

Voltage:

-

12kw

-

Certification::

-

CE Certification

-

Advantages:

-

High efficiency

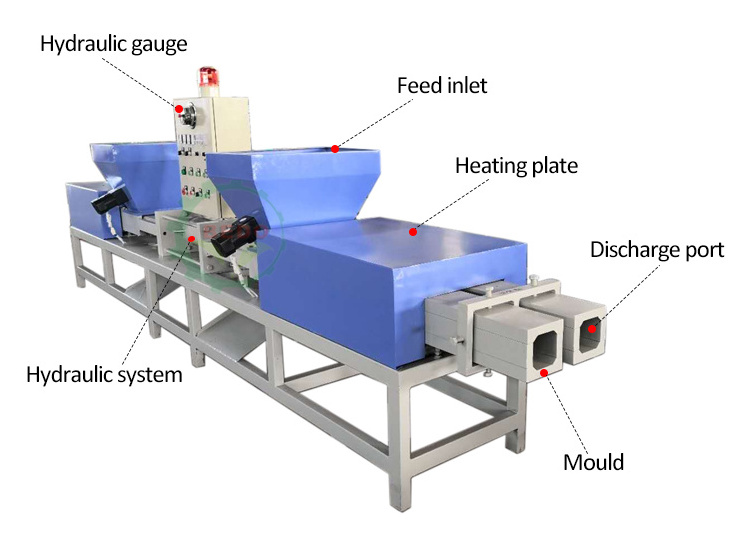

2024 Hot Selling Euro Pallet Making Machine/Wood Sawdust Block Making Machine

Product Overview

Wooden pier machine generally with wood shavings, wood chips, rotten boards, branches and other waste as raw materials, the raw materials are screened and classified to prevent the raw materials containing metal and other hard sundries and damage the machine. Then crushed by the grinder (when the raw material is less than 5*5mm, it does not need to be crushed), into the dryer drying, glue mixing machine sizing, and then through the hot press grinding tool hydraulic forming, extrusion into wooden pier products, cut into small cubes of products required by customers.

Specifications

|

Model

|

Capacity

|

Block density

|

Power

|

Weight

|

Size

|

|

BD-HP75*75

|

3-4m³/24h

|

550-600kg/m³

|

12kw

|

1050kg

|

4800*780*1320mm

|

|

BD-HP80*80

|

3-4m³/24h

|

550-600kg/m³

|

12kw

|

1100kg

|

4800*780*1320mm

|

|

BD-HP80*90

|

3-4m³/24h

|

550-600kg/m³

|

15kw

|

1150kg

|

4800*780*1320mm

|

|

BD-HP90*90

|

4-5m³/24h

|

550-600kg/m³

|

15kw

|

1200kg

|

4800*780*1320mm

|

|

BD-HP100*100

|

4-5m³/24h

|

550-600kg/m³

|

16kw

|

1300kg

|

4800*780*1320mm

|

|

BD-HP100*120

|

4-5m³/24h

|

550-600kg/m³

|

18kw

|

1350kg

|

4800*780*1320mm

|

|

BD-HP120*120

|

4-5m³/24h

|

550-600kg/m³

|

18kw

|

1400kg

|

4800*780*1320mm

|

|

BD-HP120*140

|

5-6m³/24h

|

550-600kg/m³

|

19kw

|

1450kg

|

4800*780*1320mm

|

|

BD-HP140*145

|

5-6m³/24h

|

550-600kg/m³

|

19kw

|

1500kg

|

4800*780*1320mm

|

Features & Advantages

The quality of the wooden pier hot press is advanced, the surface of the wooden pier tray feet is smooth and flat, good waterproof(no cracking after soaking in water for 48 hours, no cracking under the wind and sun), and strong nailforce.

Moulds can be customized according to the specifications and sizes of customers' requirements. The products made are exempt from inspection and fumigation, and the formaldehyde release (E2) are in line with national standards. The internal bonding strength is up to 1.07mpa. The vertical screw holding force is 1590N, and the flat behavior is 1660N, which is the ideal material for making non-fumigating wooden pallet support (foot pier, frame leg). It is mainly used to replace the foot pier used on the log pallet, which is free from fumigation and heat treatment.

Moulds can be customized according to the specifications and sizes of customers' requirements. The products made are exempt from inspection and fumigation, and the formaldehyde release (E2) are in line with national standards. The internal bonding strength is up to 1.07mpa. The vertical screw holding force is 1590N, and the flat behavior is 1660N, which is the ideal material for making non-fumigating wooden pallet support (foot pier, frame leg). It is mainly used to replace the foot pier used on the log pallet, which is free from fumigation and heat treatment.

1) Compared with the multi-layer board, the specifications are unified and the appearance is consistent, which improves the appearance and grade of the product.

2) Smooth on all sides without polishing. Good waterproof (48 hours of soaking water does not crack, wind and sun does not crack),strong nailing force. Different from the whole board cut wood chip pier, rough surface easy to drop slag;

3) Evenly heating around and in the middle, glue curing thoroughly, product strength is high.

4) Surface smooth water is not easy to penetrate, and the fiber bonding force of the shavings itself makes the products have excellent water resistance.

5) The raw material itself has more crude fiber, internal crisscross and strong structural force, so it is not easy to crack after eating nails.

6) Moulds are customized according to the specifications and sizes required by customers, and the products are exempted from export inspection and fumigation, and the formaldehyde emission (E2 can be provided as SGS) all meet the national standards.

7) The equipment is less investment, the cost is less than one third of the ordinary plate press. Because of the different

principle of production technology, the gloss and waterproof of the product is no match for the wood chip pier of thick shavings and sawboards.

2) Smooth on all sides without polishing. Good waterproof (48 hours of soaking water does not crack, wind and sun does not crack),strong nailing force. Different from the whole board cut wood chip pier, rough surface easy to drop slag;

3) Evenly heating around and in the middle, glue curing thoroughly, product strength is high.

4) Surface smooth water is not easy to penetrate, and the fiber bonding force of the shavings itself makes the products have excellent water resistance.

5) The raw material itself has more crude fiber, internal crisscross and strong structural force, so it is not easy to crack after eating nails.

6) Moulds are customized according to the specifications and sizes required by customers, and the products are exempted from export inspection and fumigation, and the formaldehyde emission (E2 can be provided as SGS) all meet the national standards.

7) The equipment is less investment, the cost is less than one third of the ordinary plate press. Because of the different

principle of production technology, the gloss and waterproof of the product is no match for the wood chip pier of thick shavings and sawboards.

Raw Materials and Final Production

Raw Material

: Wood Sawdust, wood shavings, wood chips, waste wood, used pallet and so on, also the glue(Urea formaldehyde resin&UF resin).

The Production Line

Crusher or Wood shaving machine

(it is used for the raw material with much large size)

Please use wood shavings and sawdust to make pallets. If the raw material is not very big, it is

unnecessary to crush.

Dryer machine

Drying the raw material to keep the 10%-15% moisture.

Gluing machine

Mixing the material together tighter for next step.

Hot press machine (main machine of the wood block production line)

Three types of models of the hot press machine

Please use wood shavings and sawdust to make pallets. If the raw material is not very big, it is

unnecessary to crush.

Dryer machine

Drying the raw material to keep the 10%-15% moisture.

Gluing machine

Mixing the material together tighter for next step.

Hot press machine (main machine of the wood block production line)

Three types of models of the hot press machine

Contact Us

2024 Hot Selling Euro Pallet Making Machine/Wood Sawdust Block Making Machine

2024 Hot Selling Euro Pallet Making Machine/Wood Sawdust Block Making Machine

2024 Hot Selling Euro Pallet Making Machine/Wood Sawdust Block Making Machine

Hot Searches