- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/50HZ

-

Power:

-

22000

-

Dimension(L*W*H):

-

customized

-

Weight:

-

customized

-

Application fields:

-

Candy snack food factory

-

Machinery Capacity:

-

50-600kg/h

-

Machinery Function:

-

producing gummy candy

-

Raw material:

-

pectin, gelatin

-

Name:

-

gummy candy make machine

-

Power Source:

-

Elecrtic gummy machine

-

Keywords:

-

gummy bear machine

-

Material:

-

SUS304 Stainless Steel

-

Candy shapes:

-

Custom Designed

-

Feature:

-

High Efficiency Easy Operation

-

Candy Weight:

-

2-8g

-

Processing Types:

-

Automatic Line

-

Final product:

-

Soft gummy jelly center fill candy

-

Suitable for:

-

Candy Food Production

Quick Details

-

Model Number:

-

IE-JCPL-15D

-

Brand Name:

-

IE

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V/50HZ

-

Power:

-

22000

-

Dimension(L*W*H):

-

customized

-

Weight:

-

customized

-

Application fields:

-

Candy snack food factory

-

Machinery Capacity:

-

50-600kg/h

-

Machinery Function:

-

producing gummy candy

-

Raw material:

-

pectin, gelatin

-

Name:

-

gummy candy make machine

-

Power Source:

-

Elecrtic gummy machine

-

Keywords:

-

gummy bear machine

-

Material:

-

SUS304 Stainless Steel

-

Candy shapes:

-

Custom Designed

-

Feature:

-

High Efficiency Easy Operation

-

Candy Weight:

-

2-8g

-

Processing Types:

-

Automatic Line

-

Final product:

-

Soft gummy jelly center fill candy

-

Suitable for:

-

Candy Food Production

Product Description

Introduction

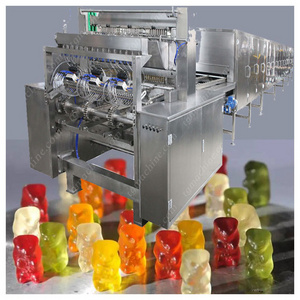

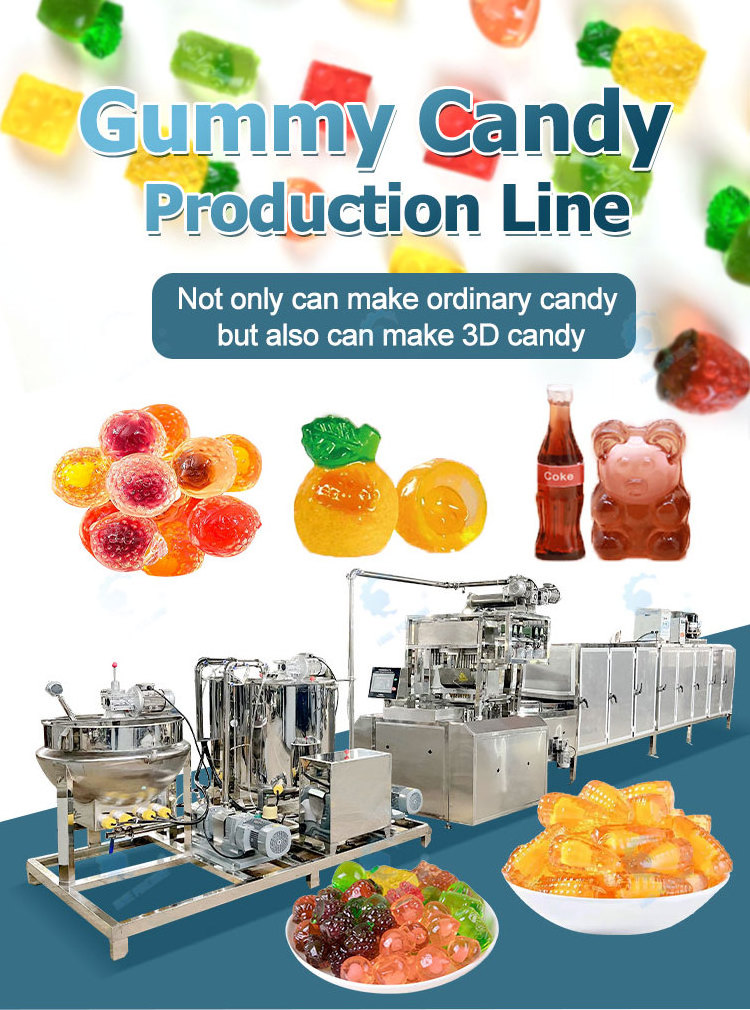

This candy production line is a multifunctional candy production line controlled by PLC, which can arrange pouring in four rows at the same time, used to make 3D sandwich gummies, fruit gummies, vegetable gummies, and ordinary flat gummies.

Application

The 4D gummy candy production line is suitable for the production of various novel -shaped center fill gummy candy. Such as eyeballs candy, vitamin gummy bear candy, fruit jelly candy, etc.

Features

1.

The machine runs stable, the color distribution of the poured candy is even.

2.

Large production capacity, up to four rows of pouring can be carried out simultaneously.

3.

The whole line is controlled by PLC, which can reduce the use of manual labor.

4.

The production line can accurately control the concentration and viscosity of the syrup, avoiding waste and loss caused by operational errors, and saving raw material costs.

5.

Free formula can be provided for on-site installation and debugging.

Parameter

|

Model

|

IE-150

|

IE-300

|

IE-450

|

IE-600

|

|||

|

Standard production volume

|

150kg/h

|

300kg/h

|

450kg/h

|

600kg/h

|

|||

|

Candy weight

|

2-8g

|

2-8g

|

2-8g

|

2-8g

|

|||

|

Pouring Speed

|

45-55n/min

|

45-55n/min

|

45-55n/min

|

45-55n/min

|

|||

|

Steam demand

|

0.2m³/min

0.4-0.6Mpa

|

0.2m³/min

0.4-0.6Mpa

|

0.2m³/min

0.4-0.6Mpa

|

0.2m³/min

0.4-0.6Mpa

|

|||

|

Work environment requirements

|

Temperature 20-25℃

Humidity 55%

|

|

|

|

|||

|

Power

|

18kw/380V

|

27kw/380V

|

34kw/380V

|

38kw/380V

|

|||

|

Overall length

|

15m

|

17m

|

17m

|

20m

|

|||

|

Overall weight

|

3500kg

|

4000kg

|

4500kg

|

5000kg

|

|||

Product Details

Product Photograph

Related Products

Packing & Shipping

Install waterproof membrane to reduce dust and water pollution.

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation.

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation.

Hot Searches