- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-45KW

-

Weight:

-

355

-

Dimension(L*W*H):

-

depend on model

-

Name:

-

fruit/vegetable/wine/juice extraction

-

Throughput:

-

1-6 T/H

-

Drum Speed:

-

3300 r/min

-

Discharge way:

-

automatic

-

Application:

-

all kinds of oil

-

Motor Power:

-

11KW

-

Drum diameter:

-

260mm

-

Noise level:

-

≤90 dB(A)

-

Control System:

-

Siemens PLC Control Box

Quick Details

-

Place of Origin:

-

JiangSu,China, JiangSu,China

-

Brand Name:

-

FIVEMEN

-

Voltage:

-

220v/380v/460v

-

Power:

-

15-45KW

-

Weight:

-

355

-

Dimension(L*W*H):

-

depend on model

-

Name:

-

fruit/vegetable/wine/juice extraction

-

Throughput:

-

1-6 T/H

-

Drum Speed:

-

3300 r/min

-

Discharge way:

-

automatic

-

Application:

-

all kinds of oil

-

Motor Power:

-

11KW

-

Drum diameter:

-

260mm

-

Noise level:

-

≤90 dB(A)

-

Control System:

-

Siemens PLC Control Box

Product Description

Main Features :

3 The main body of the decanter centrifuge made from stainless stee: SS304/SS316/Titanium Alloy

4 The screw propeller made from stainless steel (SS304/SS316) protected by Tungsten carbide alloy or Ceramic

5 Solids discharge stainless steel protected by high-chromium iron

6 Solids Liquid separation system package available

7 Germany FAG/SKF brand bearings

8 Eletrical Components: SIEMENS/Schneider/ABB

It is widely used in chemical, light industry, pharmacy, food, environment protection and other trades. For instance: Oxalic acid, alum, aluminum hydroxide, ammonium hydrogen carbonate, ammonium chloride, ammonium nitrate, ammonium sulfate, anthracene, antibiotics, barium chloride, barium carbonate, barium sulfate, benzene, blood products, blue vitriol, borax, boric acid, calcium carbonate, calcium citrate, calcium hydroxide, calcium nitrate, calcium oxalate, casein, cellulose, chrome yellow, clay, methyl cellulose, corundum, corn embryo, cooking oil, processed fish, mirabilite, glutamate, hops, pesticide, diatomaceous earth, herbicide, diatomaceous earth, herbicide, tartaric acid, sodium sulfate, sodium phosphate, sodium nitrate, carbon black and others.

|

LW two phase |

|||

|

Type No. |

Length to diameter ratio |

Drum speed (r/min) |

Motor power(KW) |

|

LW260 |

3.5-4 |

5000 |

7.5-11 |

|

LW355 |

2-4.5 |

4200 |

11-37 |

|

LW420 |

2-4.5 |

3800 |

15-45 |

|

LW450 |

2-4.5 |

3300 |

18.5-45 |

|

LW480 |

2-4.5 |

3000 |

18.5-55 |

|

LW530 |

2-4 |

3450 |

22-75 |

|

LW650 |

2-4 |

2800 |

37-110 |

|

LW750 |

2-4 |

2500 |

55-132 |

|

Three phase: |

|||

|

Type No. |

|

|

|

|

LW355 |

2-4 |

4000 |

11-30 |

|

LW420 |

2-4 |

3600 |

15-37 |

|

LW530 |

2-4 |

3000 |

18.5-45 |

Detailed Images

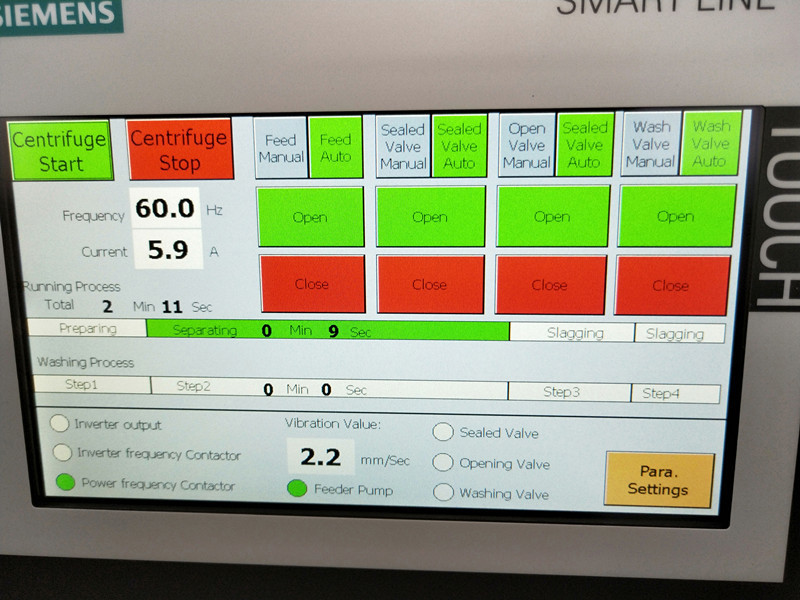

PLC Control Panel

The electrical control adopts the double conversion auto control system, which can display the parameters such as frequency, rotation speed, differential speed and current of operating major and auxiliary electrical engine.

Eletrical Components: SIEMENS/Schneider/ABB

Drum

The drum is cast by 304 stainless steel in centrifugal casting, the forging process is adopted , which can enhance its corrosion resistance, The replaceable alloy sleeve is installed in the solid state outlet, so that the mother material of the drum's outlet is not worn, and the wear-resistant bar is installed in the drum to make the drum inside not worn.

Spiral feeder

The spiral feeder is made of 304 stainless steel, and the forging process is adopted , which can enhance its corrosion resistance. BD structure, spraying hard alloy powder on the surface of the blade. The thickness is over 3mm .The spiral outlet is equipped with a replacement hard alloy sleeve, which greatly prolongs the service life of the machine blade. Because of this technology, the maintenance cost of the machine is greatly reduced. Other parts in contact with the material are 304 stainless steel.

Large end cap shaft

Our Service

Pre-Sales Service After-Sales Service

* Inquiry and consulting support. * Engineers available to service machinery overseas

* Sample testing support. * Training how to instal the machine, training how to use the machine

* View our Factory.

Our Company