- Product Details

- {{item.text}}

Quick Details

-

Material:

-

/, FRP/GRP/SMC

-

Weight:

-

/

-

Size:

-

/

-

Power:

-

/

-

Productivity:

-

/

-

Weight (KG):

-

120 kg

-

color:

-

white

-

Capacity:

-

0.25M3-5000M3

-

Panel size:

-

0.5*0.5m,1*0.5m,1*1m,1*2m

-

Panel thickness:

-

6mm-24mm

Quick Details

-

Core Components:

-

PANEL

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GRAD

-

Material:

-

/, FRP/GRP/SMC

-

Weight:

-

/

-

Size:

-

/

-

Power:

-

/

-

Productivity:

-

/

-

Weight (KG):

-

120 kg

-

color:

-

white

-

Capacity:

-

0.25M3-5000M3

-

Panel size:

-

0.5*0.5m,1*0.5m,1*1m,1*2m

-

Panel thickness:

-

6mm-24mm

Product Description

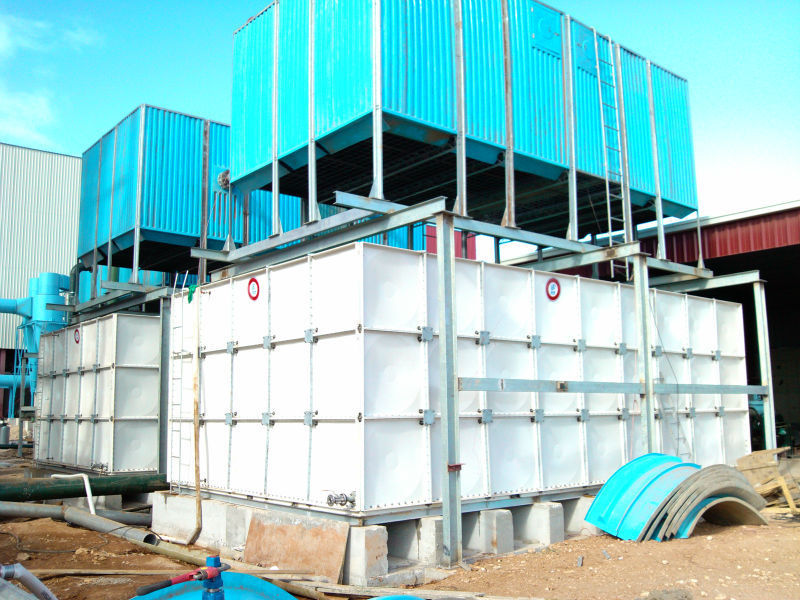

FRP water tank combination is widely used new-model water tank at present. The whole body is combined by great quality SMC slabs. It possesses many advantages as follows: anti-corrosion, beautiful appearance, no distorsion, light weight, long service life and convenient maintenance management, etc.

It is widely used in mine industry,enterprise and public institutions, house, hotels, etc. It can also serves as the water storage facility for drinking water, sewage water, fire water, and others.

It is widely used in mine industry,enterprise and public institutions, house, hotels, etc. It can also serves as the water storage facility for drinking water, sewage water, fire water, and others.

Brief introduction

(1) factory direct selling.

(2)Specializing in the production of water tank more than 20 years.

(3) Professional engaged in water tank design, production and installation.

(4) food grade sheet molding compound panel.

(5) Product diversification: SMC/FRP/GRP water tank, stainless steel water tank, hot dip galvanized water tank, etc.

(6)Multiple sizes:1*2m, 1*1m, 1*0.5m, 0.5*0.5m,also can be customized according to customers requirement.

(7)Wide application: as the storage equipment for drinking water, reclaimed water and fire water,water tank has widely used in mining, residential buildings, hotels, office buildings, schools, restaurants and other public facilities.

(8)water tank's thermal insulation: all kinds of water tank can were the thermal insulation coat to deal with temperature

extremes.

(9)Tank of different height uses different bottom panels, side panels and top panels strictly according to the assemble principle.

(10)The assemble principle guarantees safety coefficient by reasonable saving of materials. It can serve more than 50 years.

(1) factory direct selling.

(2)Specializing in the production of water tank more than 20 years.

(3) Professional engaged in water tank design, production and installation.

(4) food grade sheet molding compound panel.

(5) Product diversification: SMC/FRP/GRP water tank, stainless steel water tank, hot dip galvanized water tank, etc.

(6)Multiple sizes:1*2m, 1*1m, 1*0.5m, 0.5*0.5m,also can be customized according to customers requirement.

(7)Wide application: as the storage equipment for drinking water, reclaimed water and fire water,water tank has widely used in mining, residential buildings, hotels, office buildings, schools, restaurants and other public facilities.

(8)water tank's thermal insulation: all kinds of water tank can were the thermal insulation coat to deal with temperature

extremes.

(9)Tank of different height uses different bottom panels, side panels and top panels strictly according to the assemble principle.

(10)The assemble principle guarantees safety coefficient by reasonable saving of materials. It can serve more than 50 years.

STEP-BY-STEP ASSEMBLY

Step 1. Install steel footings on leveled concrete foundations.

Step 2. Align GRP panels to be pre-assembled.

Step 3. Place rubber sealant from ready-to-use roll between panels.

Step 4. Connect panels with bolts and nuts.

Step 5. Position bottom panel sections, and finish up base of tank.

Step 6. Position three sides of the tank.

Step 7. Position and fix roof panels and if required, roof support pipes and plates.

Step 8. Install reinforcement if required.

Step 9. Close up the tank with the fourth side.

Step 10. Finish the internal or external reinforcement.

Step 11. Fill and test.

Step 1. Install steel footings on leveled concrete foundations.

Step 2. Align GRP panels to be pre-assembled.

Step 3. Place rubber sealant from ready-to-use roll between panels.

Step 4. Connect panels with bolts and nuts.

Step 5. Position bottom panel sections, and finish up base of tank.

Step 6. Position three sides of the tank.

Step 7. Position and fix roof panels and if required, roof support pipes and plates.

Step 8. Install reinforcement if required.

Step 9. Close up the tank with the fourth side.

Step 10. Finish the internal or external reinforcement.

Step 11. Fill and test.

Specification

|

parameter

|

GRAD water tank

|

Other water tank

|

|

Tensile strength(Mpa)

|

≥60

|

≥60

|

|

Bending strength(Mpa)

|

≥120

|

≥100

|

|

Bending modulus(Gpa)

|

≥7.0

|

-

|

|

Pap hardness

|

≥60

|

≥60

|

|

Bibulous rate(%)

|

≤0.5

|

≤1.0

|

|

Glass fiber content(%)

|

≥27

|

≥25

|

|

Maximum distortion of side wall

|

≤0.5%

|

≤0.5%

|

|

distortion of the bottom

|

≤8mm.

|

≤8mm.

|

Project show

GRAD frp water tank had exported into Spain,Philippines, South Africa, Iran, Australia, Colombia, Lebanon, The united Arab emirates and so on.And it gained good honor with its high quality and good price.

Project in South Africa

Project in Bengal

Project in Equatorial Guinea

Project in Samoa

Project in Columbia

Project in Philippines

Hot Searches