- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

14500 kg

-

Product name:

-

Plywood Production Line

-

Material of inner tank:

-

Stainless steel

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

Marketing Type:

-

New Product 2020

-

Machinery Test Report:

-

Provided

Quick Details

-

Place of Origin:

-

Shandong, China

-

Type:

-

plywood production line

-

Brand Name:

-

Shining

-

Weight (KG):

-

14500 kg

-

Product name:

-

Plywood Production Line

-

Material of inner tank:

-

Stainless steel

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

Marketing Type:

-

New Product 2020

-

Machinery Test Report:

-

Provided

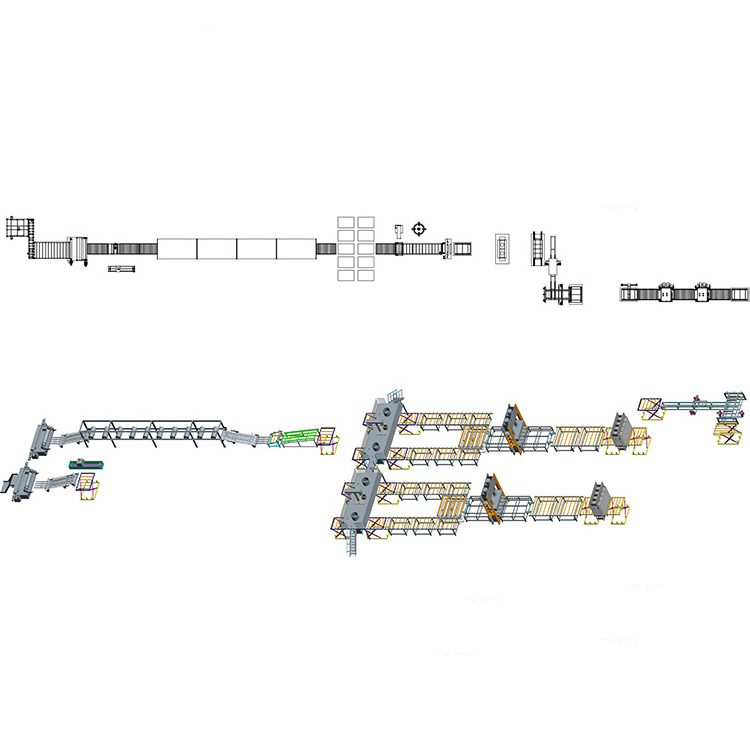

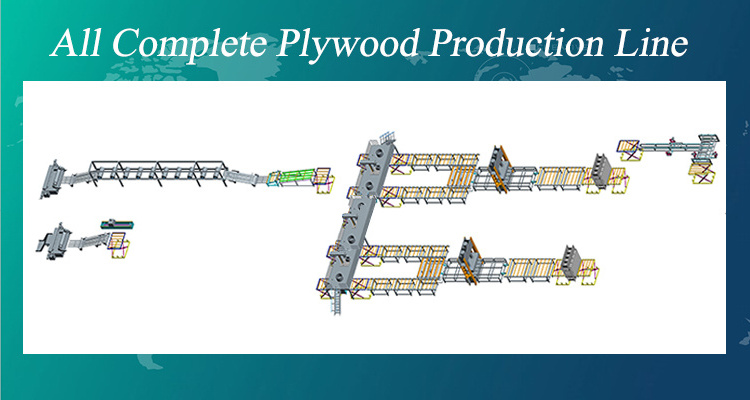

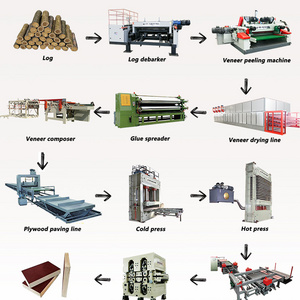

Full set

plywood production line

for plywood making: High efficiency, labor-saving, energy-saving and improving the capacity.

Product Paramenters

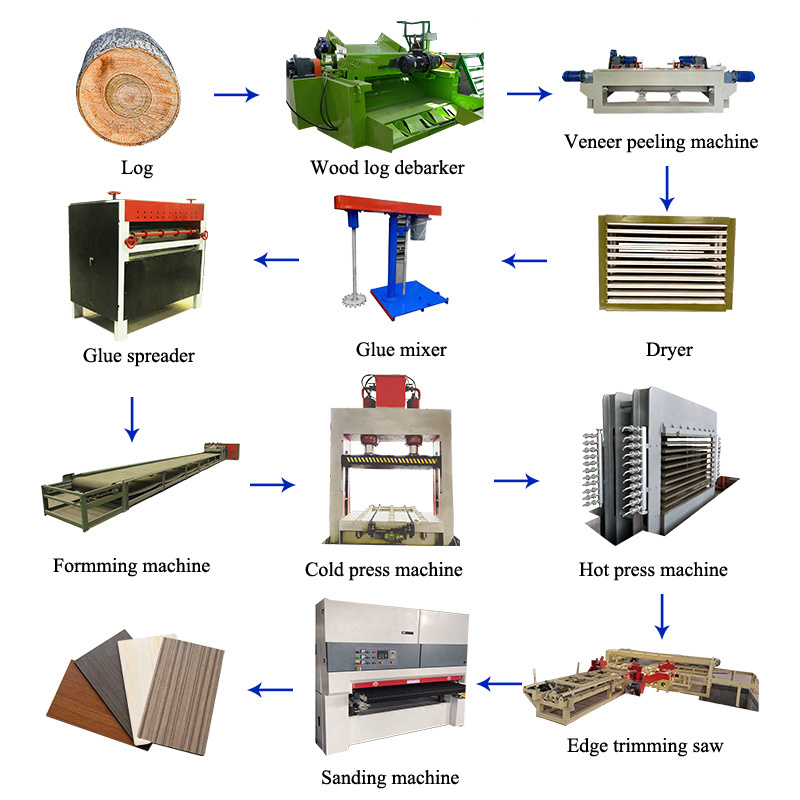

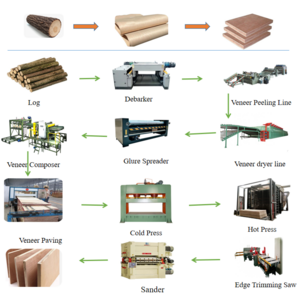

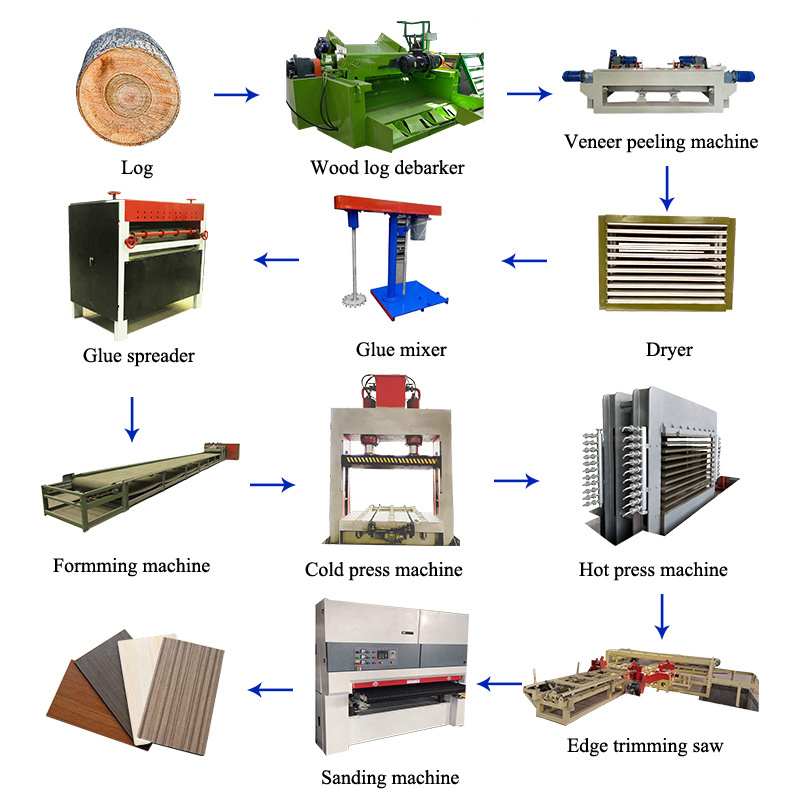

Log Debarker

One set log debarker can supply 2 set peeling machine, it saves the original manual peeling, rounding procedure, save 5-6 human.

Veneer Peeling Machine

Stable structure, high strength and wear resistance, stable rear axle rotation system. High automaticity, PLC and touch screen: mitsubishi/Siemens/schneider electric system. Labor saving, the whole veneer production line only needs one worker.

Dryer Machine

The dryer machine is used for pre-pressing process of making plywood. The whole structure is designed and manufactured based on advanced international experience and new technological requirements. Simple design, easy operate, low cost but excellent performance.

Glue Mixer

This glue mixer usually works together with plywood glue spreader, used to mix glue evenly. Our glue mixer adopts vertical structure. Raw materials feeding into the charging basket, raw materials driven by the knife along the barrel wall clockwise rotate and filp, at the save time adding the glue when the blade moving. No matter what the shape/size/density of the material, the machine can make the material and adhesive buoyancy in instant weightlessness, which makes the material within the omni-directional continuous loop turn, mutual crisscross.

Glue Spreader Machine

The glue spreader applies to plywood, multilayer board, veneer, core-board for one-sided glue, using the pure natual rubber. The machine has the feature of gluing, no marking and simple operation. It is also the preferred equipment for the decorative panel. Easy maintenance, uniform coating, high efficiency, saving glue and labor, saving production costs. We can design and manufacture any size according to user's requirements.

Plywood Forming Machine

The plywood forming machine has the following features: 1.Forming board automatically. 2.Saving raw material. 3.High precision, 100% effective cutting guaranteed. 4.Stacking neatly, save time and labor. 5.Long service life, convenient to replace the blade, low cost. 6.With pre-press section, can gurantee the plywood structure not be destroyed when cutting, transporting and feeding to press.

Plywood Cold Press Machine

The cold press is mainly used to pre-press the gluing veneer, basic forming. It is important to improve the quality of plywood. With automatic feeding-in and out device, roller transfer is used to protect the plate and save time. The lifting cylinders are used to make the machine rise in high uniform speed and increase the production capacity.

Plywood Hot Press Machine

The plywood hot press machine has the following features: 1.

Good quality main frame--Q235 plate, strong rigidity, and ensure high pressure. 2.Frame structure, simple structure, easy to install and transport. 3.Taiwan hydraulic system, good quality and hydraulic unit, fast and accurate press, low power consumption less noisy. 4.Installing with Wuxi solid cylinders can ensure high press and durable.

Plywood Edge Trimming Saw

This machine is the ideal equipment for sizing the plywood, compared to the manual model saw, it is more precision, higher efficiency, energy-saving, labor-saving. Adopt the numerical intelligent design, the saw blades can automatically change rotary speed according to the working condition, will not be stopped by resistance, can meet the automatic stacking and saw waste removing.

Plywood Sanding Machine

This sanding production line is designed for thickness calibration, surface sanding and fine surface polishing of MDF, multi-plywood, etc. Mainly using two sets of one-side wide belt sanders and one special turnover device, you can realize two-sided sanding of man-made panel in one sanding line.

Company information

FAQ

1. Q: Can you accept OEM?

A: Yes, we can produce the m

achine

according to customers' requirements

.

2. Q: What about your products' quality?

A: We can provide you samples for quality inspection . If you order, we guarantee the quality is same with sample. In case of quality problem, we can sign agreements and our company will perform the duties.

3. Q:How about delivery?

A: When the product is ready, it can be delivered to you after your full payment. We'll provide technical guidance .

4. Q: Why does the price often change?

A: The price depends on the latest prices of the raw materials .

5. Q: How about your the price often change?

A: We have 24 hours online service and also have profession al staff to slove your doubts.

2. Q: What about your products' quality?

A: We can provide you samples for quality inspection . If you order, we guarantee the quality is same with sample. In case of quality problem, we can sign agreements and our company will perform the duties.

3. Q:How about delivery?

A: When the product is ready, it can be delivered to you after your full payment. We'll provide technical guidance .

4. Q: Why does the price often change?

A: The price depends on the latest prices of the raw materials .

5. Q: How about your the price often change?

A: We have 24 hours online service and also have profession al staff to slove your doubts.

Hot Searches