- Product Details

- {{item.text}}

Quick Details

-

Car Make:

-

tricycle

-

Warranty:

-

8 Months

-

Car Fitment:

-

Adly Moto

-

Weight:

-

25.8kg

-

Max Input Torque:

-

165N.m

-

Max Input Rotation Rate:

-

5300r/min

Quick Details

-

OE NO.:

-

NO

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

5DUTV

-

Car Make:

-

tricycle

-

Warranty:

-

8 Months

-

Car Fitment:

-

Adly Moto

-

Weight:

-

25.8kg

-

Max Input Torque:

-

165N.m

-

Max Input Rotation Rate:

-

5300r/min

Products Description

Product Features

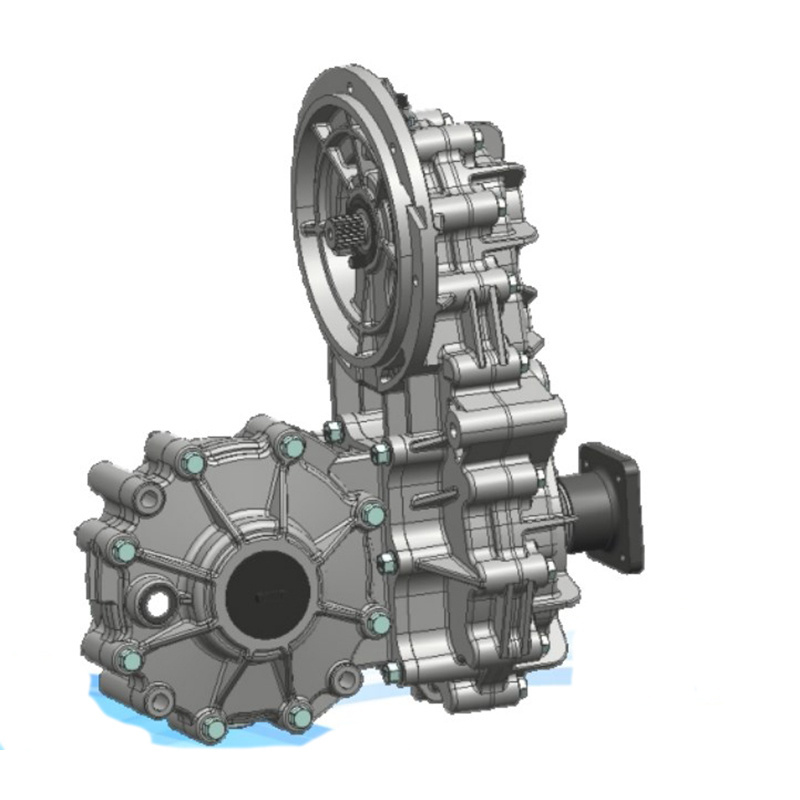

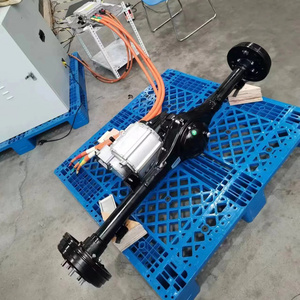

This product has been used on the rear axle of a 7.5KW four-wheel drive electric vehicle, supporting two four-wheel drive conversion and differential lock.

Rear axle assemblies are used in a variety of vehicles, including cars, trucks, and SUVs. They are responsible for transferring power from the engine to the wheels, and they also help to keep the wheels aligned and prevent them from wobbling.

There are three main types of rear axle assemblies: semi-floating, full-floating, and three-quarter floating. Semi-floating axle assemblies are the most common type, and they are used in most cars and light trucks. Full-floating axle assemblies are used in heavier vehicles, such as trucks and SUVs, and they are more durable than semi-floating axle assemblies. Three-quarter floating axle assemblies are a hybrid of semi-floating and full-floating axle assemblies, and they offer a good balance of performance and durability.

Rear axle assemblies can be made from a variety of materials, including steel, aluminum, and magnesium. Steel is the most common material, but aluminum and magnesium are becoming increasingly popular because they are lighter and stronger.Rear axle assemblies are typically serviced by a qualified mechanic. However, some basic maintenance tasks, such as greasing thebearings and checking the axle shafts for wear, can be performed by the owner.

Rear axle assemblies can be made from a variety of materials, including steel, aluminum, and magnesium. Steel is the most common material, but aluminum and magnesium are becoming increasingly popular because they are lighter and stronger.Rear axle assemblies are typically serviced by a qualified mechanic. However, some basic maintenance tasks, such as greasing thebearings and checking the axle shafts for wear, can be performed by the owner.

|

Product Performance

|

|

|

||

|

Max Input Torque

|

T max

|

165N.m

|

||

|

Max Input Rotation Rate

|

n max

|

5300r/min

|

||

|

Centre.to-centre Spacing

|

A

|

206mm

|

||

|

Gear Ratio

|

U

|

14.143:1

|

||

Here are some of the applications of rear axle assemblies:

* Transferring power from the engine to the wheels: The rear axle assembly is responsible for transferring power from the engine to the wheels. This is done by a series of gears and shafts that are housed within the axle assembly.

* Keeping the wheels aligned: The rear axle assembly also helps to keep the wheels aligned. This is important for ensuring that the vehicle drives straight and that the tires wear evenly.

* Preventing wheels from wobbling: The rear axle assembly also helps to prevent wheels from wobbling. This is done by the bearings that support the axle shafts.

Rear axle assemblies are an important part of any vehicle. They are responsible for transferring power from the engine to the wheels, keeping the wheels aligned, and preventing wheels from wobbling. Rear axle assemblies are typically made from steel,aluminum, or magnesium, and they are serviced by a qualified mechanic.

* Transferring power from the engine to the wheels: The rear axle assembly is responsible for transferring power from the engine to the wheels. This is done by a series of gears and shafts that are housed within the axle assembly.

* Keeping the wheels aligned: The rear axle assembly also helps to keep the wheels aligned. This is important for ensuring that the vehicle drives straight and that the tires wear evenly.

* Preventing wheels from wobbling: The rear axle assembly also helps to prevent wheels from wobbling. This is done by the bearings that support the axle shafts.

Rear axle assemblies are an important part of any vehicle. They are responsible for transferring power from the engine to the wheels, keeping the wheels aligned, and preventing wheels from wobbling. Rear axle assemblies are typically made from steel,aluminum, or magnesium, and they are serviced by a qualified mechanic.

|

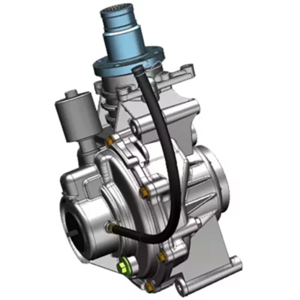

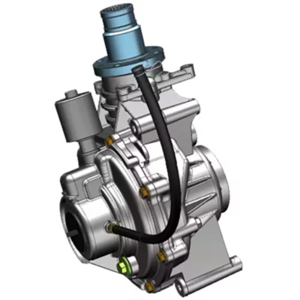

Input & Output Spline Parameters

|

|

|

|

|||

|

|

|

Input internal spline

|

Output end internal spline

|

|||

|

Tooth system

|

|

|

|

|||

|

modulus

|

m

|

1.05833

|

1

|

|||

|

number of teeth

|

z

|

19

|

22

|

|||

|

Pressure angle

|

a

|

45°

|

20°

|

|||

|

the modification coefficient

|

x

|

0.08

|

|

|||

|

Over Dimension & Weight

|

|

|

|

Weight(kg)

|

25.8

|

|

|

Length

|

420

|

|

|

AxleTrack

|

390

|

|

|

Height

|

392

|

|

|

For more details, please click here to contact us!

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

Related Products

Hot Searches