- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

650

-

Dimension(L*W*H):

-

340*255*300

-

Weight (T):

-

7 T

-

Table Travel (Z) (mm):

-

600

-

Positioning Accuracy (mm):

-

±0.0075

-

Range of Spindle Speed(r.p.m):

-

1 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

11

-

Max. Table Load(kg):

-

1000 kg

-

Feed Speed(mm/min):

-

1 - 100000 mm/min

-

Rapid Feed Speed(m/min):

-

36

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220/380/415V

-

Product name:

-

CNC Machining Center

-

Spindle Speed:

-

8000/10000/12000rpm

-

Tool Changer:

-

ATC 16/24 Tools Changer Robot

-

Guideway type:

-

Ball Linear Guideway

Quick Details

-

Table Size (mm):

-

1200x600

-

Number of Axes:

-

3, 4, 5

-

Table Travel (X) (mm):

-

1100

-

Table Travel (Y) (mm):

-

650

-

Dimension(L*W*H):

-

340*255*300

-

Weight (T):

-

7 T

-

Table Travel (Z) (mm):

-

600

-

Positioning Accuracy (mm):

-

±0.0075

-

Range of Spindle Speed(r.p.m):

-

1 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

11

-

Max. Table Load(kg):

-

1000 kg

-

Feed Speed(mm/min):

-

1 - 100000 mm/min

-

Rapid Feed Speed(m/min):

-

36

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220/380/415V

-

Product name:

-

CNC Machining Center

-

Spindle Speed:

-

8000/10000/12000rpm

-

Tool Changer:

-

ATC 16/24 Tools Changer Robot

-

Guideway type:

-

Ball Linear Guideway

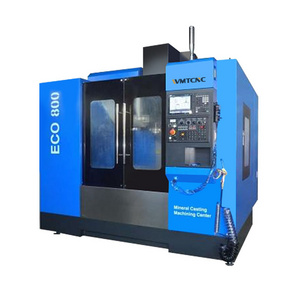

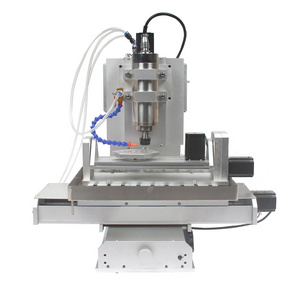

Products Performance

This VMC is suitable for mechanical processing and mold making .And it can asapt to the processing requirement from rough machining to finish machining .It can also finish many working procedures like milling ,drilling ,tapping ,boring ,etc.

High quality resin sand

Taiwan spindle

Taiwan ball screw and locking nut

Taiwan pressure cylinder

Japanese NSK bearing germany R+W coupling

Automatic lubrication system

Chip conveyor at optional

High quality resin sand

Taiwan spindle

Taiwan ball screw and locking nut

Taiwan pressure cylinder

Japanese NSK bearing germany R+W coupling

Automatic lubrication system

Chip conveyor at optional

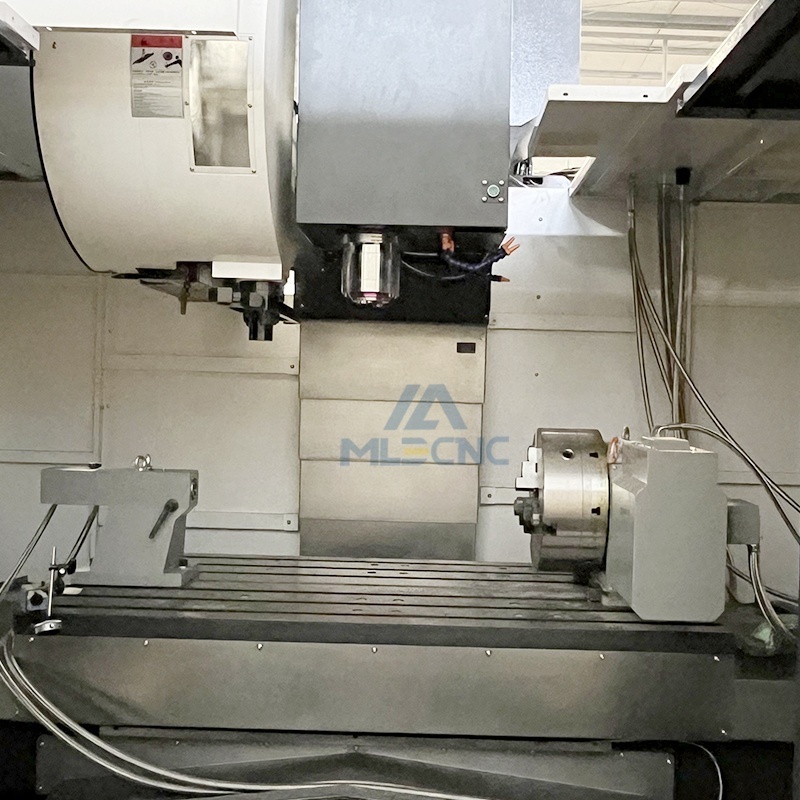

Machine Photos

Standard Accessories

STANDARD ACCESSORIES

- X/Y/Z Axis servo motor torque 22/22/22 NM

- Linear guides (roller type) : Taiwan Hiwin, made in Taiwan

- Ball screw: Taiwan Hiwin, made in Taiwan

- Bearing: Japan NTN or NSK, made in Japan

- Automatic lubrication system: Japan

- Pressure cylinder: Taiwan

- Electrical components: Schneider, Siemens

- Workbench T-Slot (number and size) 5x18x95mm

- The controller GSK25I with GSK drives and motors

- Spindle brand is VOLIS or VYUCHENG, all from Taiwan

- oil cooler for spindle, the brand name: Diort, it's from Taiwan, watt capacity 20L.

- Mass balance for Z aixs

- X/Y/Z Axis servo motor torque 22/22/22 NM

- Linear guides (roller type) : Taiwan Hiwin, made in Taiwan

- Ball screw: Taiwan Hiwin, made in Taiwan

- Bearing: Japan NTN or NSK, made in Japan

- Automatic lubrication system: Japan

- Pressure cylinder: Taiwan

- Electrical components: Schneider, Siemens

- Workbench T-Slot (number and size) 5x18x95mm

- The controller GSK25I with GSK drives and motors

- Spindle brand is VOLIS or VYUCHENG, all from Taiwan

- oil cooler for spindle, the brand name: Diort, it's from Taiwan, watt capacity 20L.

- Mass balance for Z aixs

OPTIONAL ACCESSORIES

- Siemens 808D ADAVANCE

- Fanuc 0i MF

- Chip conveyor

- Spindle belt type 10000 rpm

- Spindle direct type 12000 rpm

- Spindle taper BT50 speed 6000 rpm

- 4axis 250mm/320mm

- 16pcs armless Taiwan OKADA tool changer

- 24pcs arm type Taiwan OKADA tool changer

- Fanuc 0i MF

- Chip conveyor

- Spindle belt type 10000 rpm

- Spindle direct type 12000 rpm

- Spindle taper BT50 speed 6000 rpm

- 4axis 250mm/320mm

- 16pcs armless Taiwan OKADA tool changer

- 24pcs arm type Taiwan OKADA tool changer

Product Paramenters

|

SPECIFICATION

|

unit

|

VMC1165

|

VMC1167

|

|||

|

Table size

|

mm

|

1200×600

|

1200×600

|

|||

|

Travel (X/Y/Z)

|

mm

|

1100×650×600

|

1100×600×700

|

|||

|

Distance from spindle to worktable

|

mm

|

120-720

|

100-800

|

|||

|

Distance from spindle center to column

|

mm

|

665

|

650

|

|||

|

Max. table loading

|

kg

|

1000

|

1000

|

|||

|

T-slot (No.×width×pitch)

|

mm

|

5-18×100

|

5-18×100

|

|||

|

Spindle

|

|

|

|

|||

|

Spindle taper

|

|

BT40-150/BT50-150

|

|

|||

|

Main motor

|

kw

|

11/15

|

|

|||

|

Speed of spindle

|

rpm

|

8000rpm or more

|

|

|||

|

Spindle drive

|

|

Belt drive/Gear drive

|

|

|||

|

Feed

|

|

|

|

|||

|

Guide way

|

|

X/Y/Z Linear guide way

|

|

|||

|

Cutting feed speed

|

m/min

|

0-10

|

|

|||

|

Rapid feeding(X/Y/Z)

|

m/min

|

24×24×20

|

|

|||

|

Tool Magazine

|

|

|

|

|||

|

Tool Magazine capacity

|

pcs

|

16/20

|

|

|||

|

Tool change time

|

sec

|

7/2.5

|

|

|||

|

Max. diameter of tool

|

mm

|

100

|

|

|||

|

Max. length of tool

|

mm

|

300

|

|

|||

|

Max. weight of tool

|

kg

|

7.5

|

|

|||

|

Accuracy

|

|

|

|

|||

|

Positioning accuracy

|

mm

|

±0.0075

|

|

|||

|

Repositioning accuracy

|

mm

|

±0.005

|

|

|||

|

Machine dimension

|

mm

|

3400*2550*2960

|

3400*2500*3060

|

|||

|

Weight

|

kg

|

7000

|

7000

|

|||

Products Details

OUR COMPANY

ABOUT US

Shandong Mainland CNC Equipment Co., Ltd

Shandong Mainland Cnc Equipment Co., Ltd is a professional manufacturer. our main products are:CNC lathe machine ,CNC milling Machine,Vertical Machining Center,Lathe Machine, Milling Machine, Drilling Machine,CNC Plasma Cutting Machine,CNC Machining Center and other metal cutting machine tools, all the products above have passed CE,ISO,SGS,TUV certificates.

Our company has rich experience in manufacturing and exporting. Our CNC machine tools are exported to Europe, America, Southeast Asia and other countries and regions. Our technicians can answer your technical questions , in many cases, resolve them effectively by the phone. In order to provide the best service to customers, we will try our best to give feedback within 24 hours of your request.

Our company follows the "customer first, forge ahead" concept, to provide our customers with quality service. Common development, win-win!

Superior Customer Care

When you contact us, a knowledgeable English speaking sales engineer will be in con-tact to answer your questions. and in many cases, solve your problem effectively over the phone. In order to provide customers the best service, what your requests, including the spare parts posting requests, quality modifying , price inquiry, delivery time checking, we will try our best to feed back within 24 hours.

FAQ

Q1. How can I get a quotation?

A. Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model . You can also send us the products drawing ,we will choose the most suitable machines for you .

A. Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model . You can also send us the products drawing ,we will choose the most suitable machines for you .

Q2.What's your main products of your company?

A.We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on .

Q3. Can you provide training for operation CNC machines?

A. Yes, free training in our factory is available.

Q4. How about your price?

A. Send me details about what you need, you will get the best price in China. The price is competitive over the world.

Q5. What's your warranty terms?

A. We will supply a replacement for parts that prove to be defective for a period of 18 months, starting on the machine’s bill of lading date. Extended warranty is available at the time of purchase. Please contact your sales representative for details.

Q6. What’s the delivery time, and what’s the package?

A. Normally the delivery time is about 30-45 days. All our CNC machines are packed with sea worthy package.

Q7. What is your trade terms?

Q3. Can you provide training for operation CNC machines?

A. Yes, free training in our factory is available.

Q4. How about your price?

A. Send me details about what you need, you will get the best price in China. The price is competitive over the world.

Q5. What's your warranty terms?

A. We will supply a replacement for parts that prove to be defective for a period of 18 months, starting on the machine’s bill of lading date. Extended warranty is available at the time of purchase. Please contact your sales representative for details.

Q6. What’s the delivery time, and what’s the package?

A. Normally the delivery time is about 30-45 days. All our CNC machines are packed with sea worthy package.

Q7. What is your trade terms?

A .FOB, CFR and CIF all acceptable.

Q 8.What's the Payment Terms ?

A. T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

Q9.What's the MOQ?

A.1 set .(Only some low cost machines will be more than 1 set )

Q 8.What's the Payment Terms ?

A. T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

Q9.What's the MOQ?

A.1 set .(Only some low cost machines will be more than 1 set )

Hot Searches