- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JL-600-30

-

Name:

-

Automatic computer wire stripping and cutting machine

Quick Details

-

Use:

-

Stripping

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JULI

-

Model Number:

-

JL-600-30

-

Name:

-

Automatic computer wire stripping and cutting machine

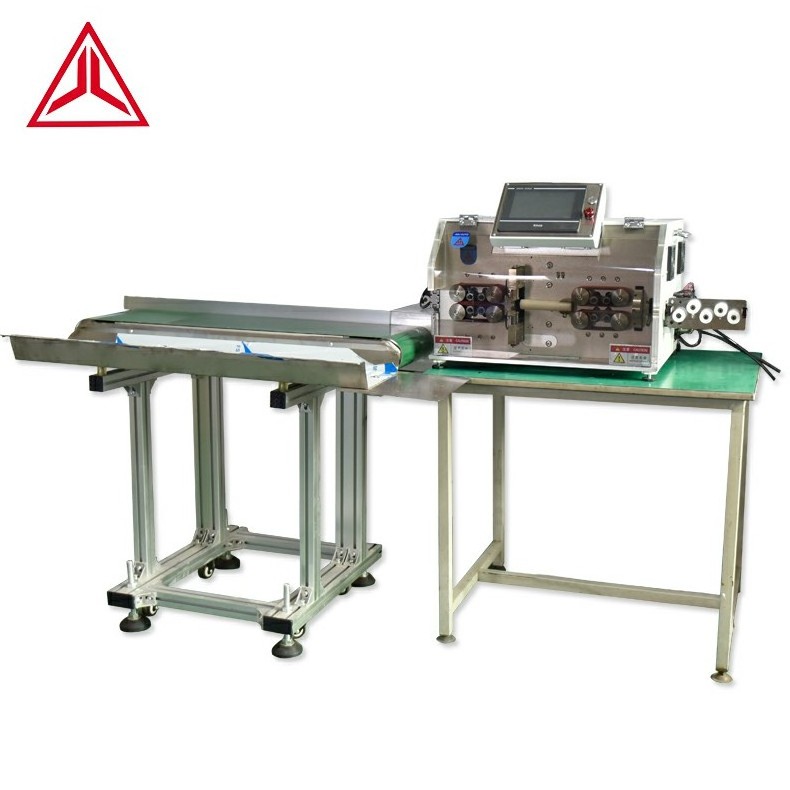

Automatic computer wire stripping and cutting machine with assembly line take-up station

This machine is mainly for automatic cutting and stripping of wires and cables. According to the required length, the stripping is cut and stripped without damaging the skin and conductors, saving labor costs and improving processing quality. Mobile tool holder, cutting and stripping are completed with different tools, the cut is neat, the stripping quality is stable, and the belt feeding precision is higher, which greatly improves the efficiency. The storage capacity of up to 100 kinds enables the complete preservation of various processing data and can be recalled at any time.

|

Model |

Large square computer wire stripping machine JL-600-30H sheathed wire type |

|

Display mode |

7 inch true color touch screen |

|

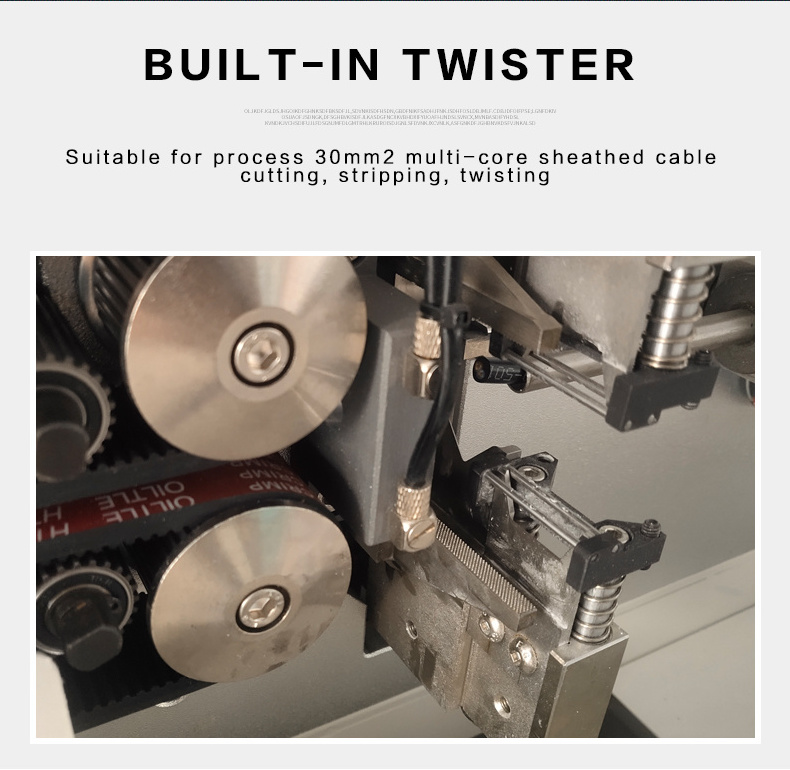

Function |

1. Wire, cable, fully automatic cutting and peeling. 2. Multi-core sheathing line Skin peeling, multi-core wire stripping, once completed |

|

Wire type |

Cable, PVC, sheathed wire, multi-core sheathed wire, etc |

|

Stripping range |

4-30 square meters (including sheath wire below 5 cores) |

|

Cutting length |

1mm-99999.99mm |

|

Cutting tolerance |

within 0.002*L (L=cut length) |

|

Weight |

50KG |

|

Size |

L600*W460*H500mm |

|

Peeling length |

before stripping: sheath line is completely off 10-120mm, core line 1-120mm After peeling: the sheath wire is completely off 10-240mm, the core wire is 1-240mm |

|

Maximum catheter diameter |

Φ 16 |

|

Tool material |

high quality imported high speed steel |

|

Productivity |

(times/hour) 2300pcs/h, (sheath line 800pcs/H) depends on the length and size of the line |

|

Drive mode |

16-wheel drive (silent hybrid stepper motor, servo tool holder) |

|

Wire feeding method |

Belt feeding line, no embossing on the cable without scratches |

|

Remarks |

Special cable can be customized, need to send sample line test |

1. Why choose us?

We provide overall solutions for processing equipment. Our standard equipment is very complete, all are in stock and can be shipped quickly. We have our own equipment factory, which can lightly customize equipment according to customer requirements, such as ordering different appearances and brands for agents, and non-standard equipment according to customer requirements.

2. Should I worry about the quality?

Before delivery, we do test the machine working condition for you.

Take a video of the normal operation of the machine to you, and then confirm the delivery

3.How can I know your machine is designed for my product?

You tell us the specific parameters of your product, or you can send us samples of your product and we test it on machine.

Video for you to make samples

4. How to operate the equipment?

My friend, don't worry about it, we have made vedio for you, it will show you how to do it step by step. Contact our engineers at any time when you don’t understand, support video and telephone communication

5.When the machine can't work well,What should I do?

The Engineer is online for 24-hours, they can check the problems and then give you solution way very soon. Please rest assured that manual will be offered along with machine,ensuring you can operate the machine easily.