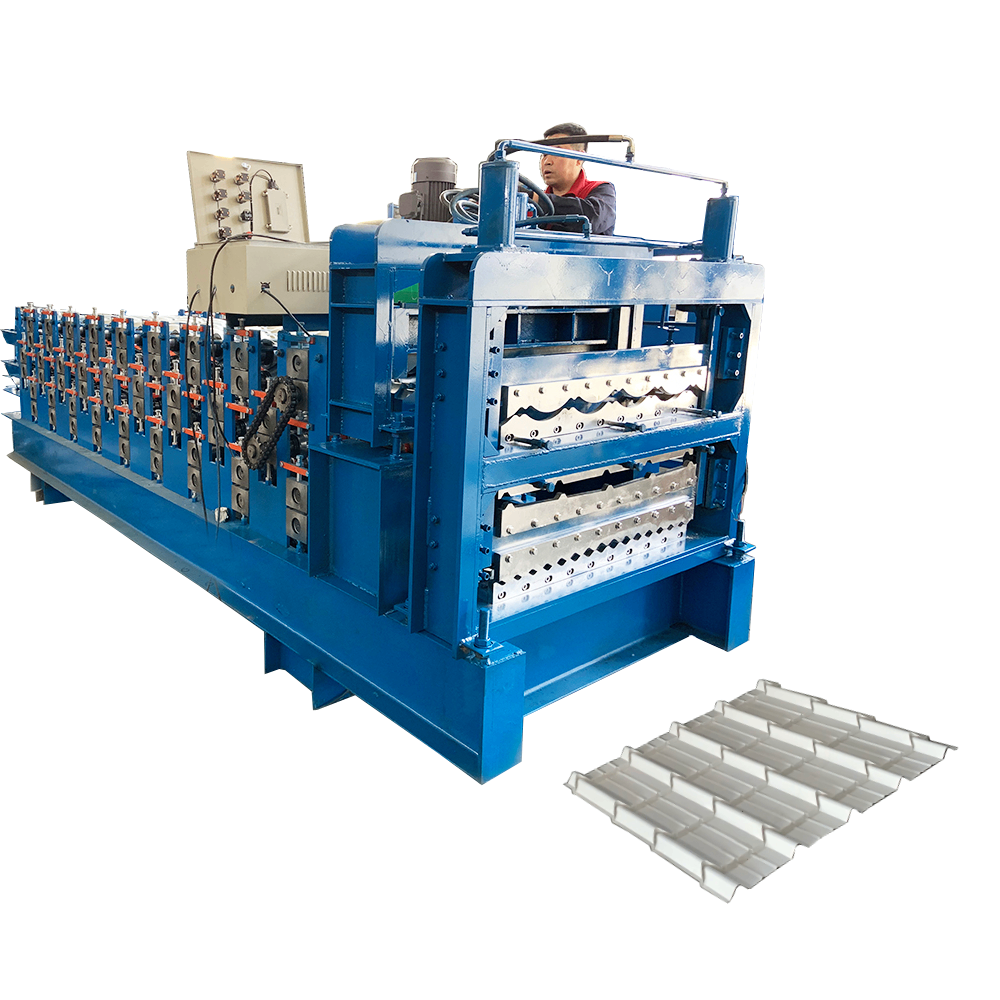

The tile forming machine is a machine composed of uncoiler, forming, and post-forming cutting. Its color plate has a flat and beautiful appearance, uniform paint pattern, high strength and durability. It is widely used in industrial and civil buildings,such as workshops, warehouses, gymnasiums, exhibition halls, theaters and other room surfaces and walls.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Demma

-

Voltage:

-

380V 50hz 3 phases

-

Dimension(L*W*H):

-

8500mm*1650mm*1500mm

-

Weight:

-

6500 kg

-

Feeding width:

-

Other, 914-1450mm

-

Marketing Type:

-

New Product

-

Name:

-

3 Layers Roll Forming Machine

-

Shaft material:

-

45# Steel

-

Thickness:

-

0.3--0.8mm

-

Decoiler:

-

5T Manual Decoiler

-

Material of rollers:

-

CR 12

-

Main frame:

-

350-500mm H-beam Steel

-

Raw material:

-

PPGI PPGL GI GL

-

PLC:

-

DELTA(TAIWAN)or Mitsubishi(JAPAN)

-

Special requirements:

-

OEM

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

Other

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Demma

-

Voltage:

-

380V 50hz 3 phases

-

Dimension(L*W*H):

-

8500mm*1650mm*1500mm

-

Weight:

-

6500 kg

-

Feeding width:

-

Other, 914-1450mm

-

Marketing Type:

-

New Product

-

Name:

-

3 Layers Roll Forming Machine

-

Shaft material:

-

45# Steel

-

Thickness:

-

0.3--0.8mm

-

Decoiler:

-

5T Manual Decoiler

-

Material of rollers:

-

CR 12

-

Main frame:

-

350-500mm H-beam Steel

-

Raw material:

-

PPGI PPGL GI GL

-

PLC:

-

DELTA(TAIWAN)or Mitsubishi(JAPAN)

-

Special requirements:

-

OEM

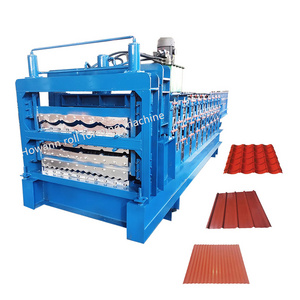

Three Layer Trapezoidal Roofing Iron Sheet Roof Tiles Making Machine

Send me an inquiry now for more discounts! !

Product Description

We are professional manufacturers, product quality and price are guaranteed

Working flow

C

ONTACT US

24 hours online service!!!

Specification

Three Layer Trapezoidal Roofing Iron Sheet Roof Tiles Making Machine

send me inquiry now ,for more discount!!

- Parameter of Roll forming machine

|

Processing material

|

aluzinc/galvanized steel/colored steel coil

|

|

Material thickness

|

0.3mm-0.8mm

|

|

Feeding width

|

1200mm or customer request

|

|

Effective width

|

As drawing or customer request

|

|

Main motor power

|

4kw

|

|

Hydraulic pump power

|

4kw

|

|

Shaft diameter

|

75mm

|

|

Forming steps

|

13/13/13 forming steps

|

|

Main frame

|

350H steel frame

|

|

Side plate thickness

|

16mm

|

|

Roller material

|

45# forged steel, with hard chrome plating

|

|

Control systerm

|

(Taiwan brand)Delta PLC control system with touch screen

|

|

Cutting blade material

|

Cr12

|

|

Working speed

|

About 10-12m/min

|

|

Transmission way

|

1 inch chain drive

|

|

Machine size (mm)

|

8000*1650*1500mm

|

|

Machine weight

|

7 tons

|

|

Power supply

|

380v,3phase,50hz or accodring to customer request

|

Combined three layer ibr sheet iron metal roofing roll forming machinery trapezoidal tile making machine

1.This roll forming machine can form smooth and beautiful metal roofing sheet without any scratch on surface

2.Roll forming process: uncoiler, roll forming, forming step effect, cut to length.

3.Fully Automatic Control System with PLC.

4.Easy operation: Set length and quantity on the control panel,machine will auto working

5.Customized your own roll forming machine, We can design the machine according to your specification and profile drawing.

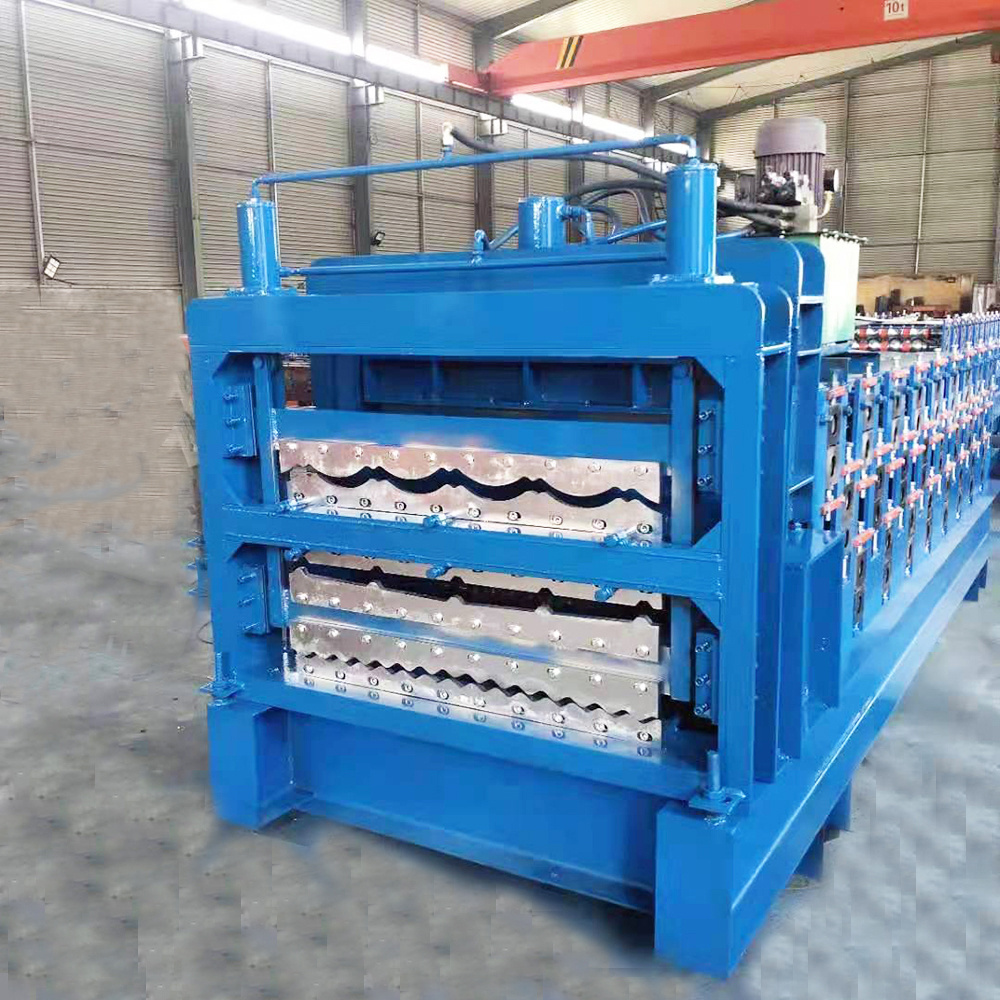

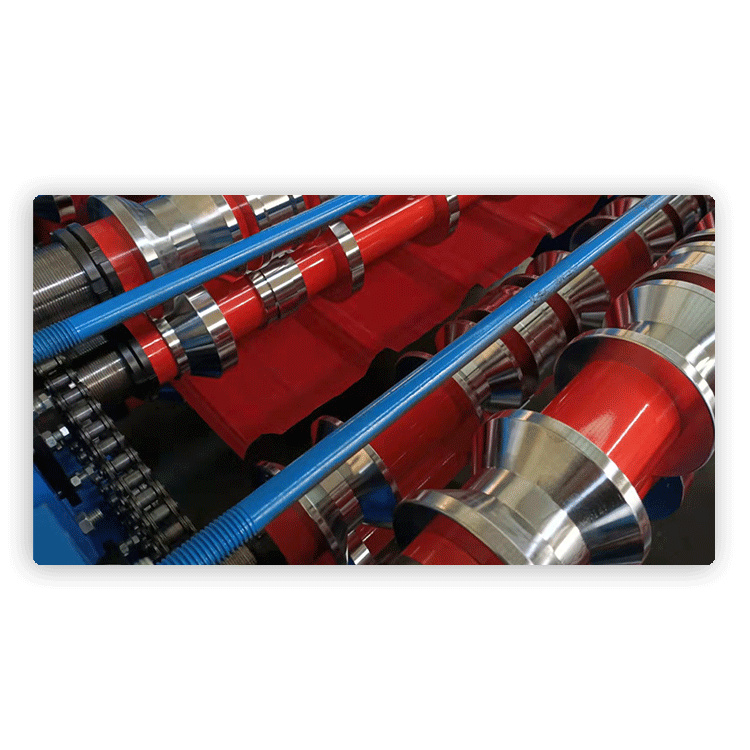

- Detail of Roll forming machine

Sidewall:14mm 45# steel plate

Material of rollers: 45# forging steel

Material of shafts: 45# steel with finish turning

Diameter of shafts: φ60mm

Number of rollers : 11rollers

Detail Images

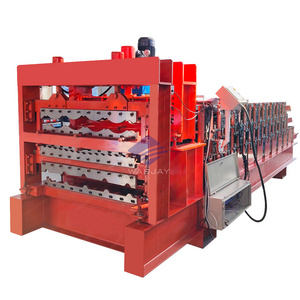

- Feature Of

Triple Layer

Roll forming machine

1. The tile formingmust use the high-number pulse input function, the high-number input performance is excellent, and the AB phase has strong anti-interference ability. And use the fixed value interrupt function to ensure the accuracy.

2. The detection part of the tile pressing machine includes: the pulse encoder for detecting the length of the colored steel tile, the up and down travel switch for the pressing, the up and down travel switch for the cutter, the up and down operation buttons for the pressing, the up and down travel button for the cutter, and the emergency stop switch , hydraulic start-stop switch, etc.

3. The executive part of the tile pressing machine has a frequency converter drive motor, a hydraulic station motor, two

hydraulic solenoid valves for pressing, and two hydraulic solenoid valves for cutters.

4. The PLC has 14 inputs/10 relay outputs, which just meets the input and output requirements. With KDN text screen, it can complete parameter setting, alarm display, help information, production data display and so on.

Shipping & Delivery

1.All export goods will be packed according to customer requirements before shipment and used in roof sheet roll forming machine.

2.Before the goods arrived destination port, we will provide customer bill of lading and clearance documents for making clearance customs.

Hot Searches