Worktable has worktable base, worktable, spindle parts and transmission device. Worktable and worktable base are whole cast iron structure, adopting high strength low stress iron casting, which has enough rigidity, strength and heat stability. Worktable spindle bearing adopts high precision double row short cylindrical roller bearing. It could ensure the worktable high precision rotation and long service life.

- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

1 - 50 r.p.m

-

Width of bed (mm):

-

1100

-

Max. Turned Length (mm):

-

50000 mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HITECH

-

Model Number:

-

C5225

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6510x4400x5340mm

-

Weight (KG):

-

20000 KG

-

CNC or Not:

-

Normal

-

Automatic Grade:

-

Automatic

-

Side Tool Post:

-

2300mm

-

Max.workpiece height:

-

1600mm

-

color:

-

optional

-

performance:

-

high precisoion

-

Weight:

-

33t

-

Power(W):

-

50HZ

-

Max. Swing Diameter:

-

2500mm

-

Power (kW):

-

50

Quick Details

-

Max. Length of Workpiece (mm):

-

5000

-

Machining Capacity:

-

Heavy Duty

-

Spindle Bore(mm):

-

102

-

Range of Spindle Speed(r.p.m):

-

1 - 50 r.p.m

-

Width of bed (mm):

-

1100

-

Max. Turned Length (mm):

-

50000 mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HITECH

-

Model Number:

-

C5225

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6510x4400x5340mm

-

Weight (KG):

-

20000 KG

-

CNC or Not:

-

Normal

-

Automatic Grade:

-

Automatic

-

Side Tool Post:

-

2300mm

-

Max.workpiece height:

-

1600mm

-

color:

-

optional

-

performance:

-

high precisoion

-

Weight:

-

33t

-

Power(W):

-

50HZ

-

Max. Swing Diameter:

-

2500mm

-

Power (kW):

-

50

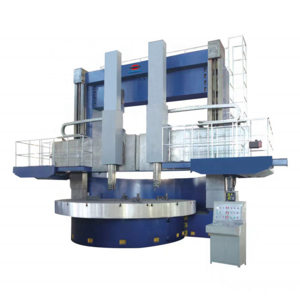

C5225 Vertical Heavy Duty Turning Lathe or Double Column

Vertical Lathe Machine

Double column vertical lathe is mainly used for the rough and fine processing and groove cutting of inside and outside cylindrical surface and circular conical surface and plane for ferrous metals, non-ferrous metals and some non-metallic parts by high speed steel and hard alloy tools.

Double column vertical lathe machine left tool rest is the non-rotation tool rest, and right tool rest is the common tool rest, which could rotate. Tool rest feeding has AC asynchronous servo feeding system with PLC control, LCD displays feeding axis position and feeding speed. Manual pulse tool setting.

Double column vertical lathe has large worktable load-bearing, high machine accuracy, high rigidity, long service life, good antiknock characteristic, strong reliability and is suitable for strong cutting.

Double column vertical lathe adopts the short spindle structure, and spindle centering bearing adopts high accuracy double row roller bearing; worktable guideway adopts constant flow hydrostatic guideway, through the equivalent oil distributor to supply the pressure oil to the static pressure oil cavity. So the radial and axial directions of the worktable have higher precision and strengthened load-bearing. Main movement is driven by spindle AC servo motor with good dynamic characteristics. And the worktable has strong instantaneous overload capacity. Feeding axis movement is that the servo motor driving the ball screw structure by the reduction box with high accuracy and accurate position.

|

No.

|

Item

|

Unit

|

Main specification

|

|

1

|

Max turning workpiece diameter

|

mm

|

2500

|

|

2

|

Max processing workpiece height

|

mm

|

1600

|

|

3

|

Worktable load-bearing weight

|

t

|

20

|

|

4

|

Worktable diameter

|

mm

|

2250

|

|

5

|

Worktable rotation speed range

|

r/min

|

0.63~63 (stepless speed regulation)

|

|

6

|

Max worktable torque

|

kN.m

|

63

|

|

7

|

Max cutting force of left tool rest

|

kN

|

30

|

|

8

|

Max cutting force of right tool rest

|

kN

|

35

|

|

9

|

Common tool rest rotation angle

|

|

±30°

|

|

10

|

Tool rest ram vertical travel

|

mm

|

1000

|

|

11

|

Tool rest horizontal travel

|

mm

|

-20~1400

|

|

12

|

Tool rest feeding speed

(X direction and Z direction) |

mm/min

|

0.5~1000

|

|

13

|

Tool rest rapid moving speed

|

mm/min

|

3000

|

|

14

|

Ram section size

|

mm

|

250×200

|

|

15

|

Max tool bar section size

|

mm

|

50×50

|

|

16

|

Max beam travel

|

mm

|

1250

|

|

17

|

Beam lifting speed

|

mm/min

|

400

|

|

18

|

Main motor power

|

kW

|

AC:55

|

|

19

|

Beam lifting motor power

|

kW

|

11

|

|

20

|

Machine weight (about)

|

t

|

35

|

Double column vertical lathe is an advanced equipment with the integration of mechanical-electrical-hydraulic, which absorbing the new design philosophy and manufacturing technology. It adopts the CAD optimization design way, equips advanced functional components at home and abroad. In structure, it achieves strong strength, high dynamic and static stiffness, high precision, heavy loading, high efficiency, long service life, safe and reliable movement. Main technical specifications of each machine parts conform to the national related standards.

Machine has worktable base, worktable, main transmission box, gantry frame, beam, ram tool rest, feeding box, electrical system, operation station, hydraulic system, protection device and so on.

Worktable

Main transmission

The main transmission system of the machine is vertical shaft transmission. It adopts spindle AC servo motor to drive; gearbox achieves mechanical two gear transformation by the shift cylinder pushing the change gear, so that the worktable could do stepless speed regulation within 0.63-63r/min.

Gantry frame

It is composed of left and right vertical columns and connecting beam. Gantry and worktable base form the sealing structure. In the upper part of the gantry, there is left and right lifting box, driven by biaxial stretching AC motor. Through gear pair, worm and gear pair and double leadscrews make the beam to do lifting movement along the left and right column guide rail.

Beam

Beam adopts high strength and low stress iron casting with enough rigidity and strength, so as to ensure the machine accuracy to have long term retentivity and stability. Beam is in front of the vertical column, and it does the vertical movement along the vertical column guideway. On the back of beam, there are 4 hydraulic clamping points. On both sides of the beam, there are feeding box for tool rest.

We are caring for our team, we are proffesional for our machines, hope could help our customers a lot when choosing machines and help sovle problems.

We are alibaba gold supplier for many years!

We have very high trade assurance amount!

Trust alibaba, trust us!

We group up with our customer