Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

ZJT

-

Model Number:

-

zjt-a112

-

Product name:

-

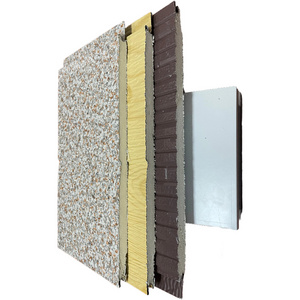

New Materials Sandwich Wall Panel for Buidling

-

Color:

-

White Grey

-

Core material:

-

EPS+Cement+Sand+additives

-

Thickness:

-

60/75/90/100/120/150mm

-

Length:

-

2270/2440mm

-

Advantage:

-

fireproof,waterproof,lightweight easy to install

-

Life span:

-

60-70 years

-

Fire endurance:

-

3-4 hours

-

Structure:

-

Costomers' Requirements

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

ZJT

-

Model Number:

-

zjt-a112

-

Product name:

-

New Materials Sandwich Wall Panel for Buidling

-

Color:

-

White Grey

-

Core material:

-

EPS+Cement+Sand+additives

-

Thickness:

-

60/75/90/100/120/150mm

-

Length:

-

2270/2440mm

-

Advantage:

-

fireproof,waterproof,lightweight easy to install

-

Life span:

-

60-70 years

-

Fire endurance:

-

3-4 hours

-

Structure:

-

Costomers' Requirements

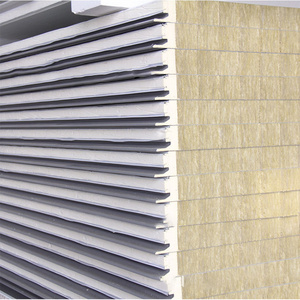

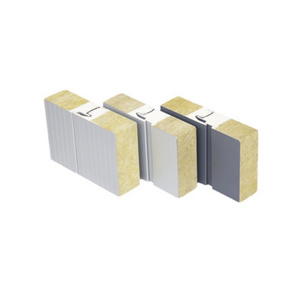

ZJT New Type Lightweight Energy Saving Composite EPS Sandwich Cement Wall Panel

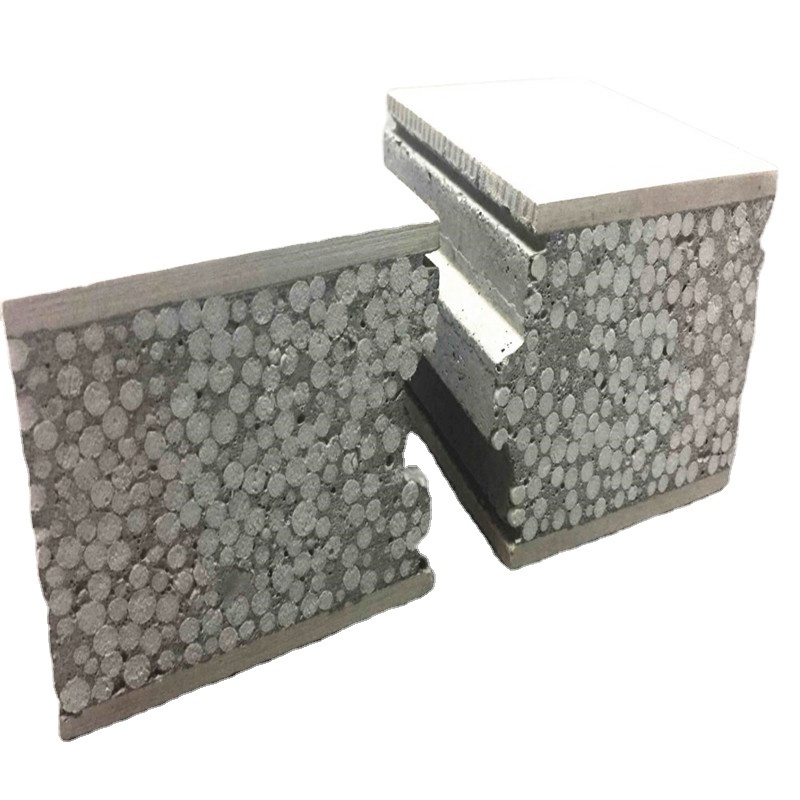

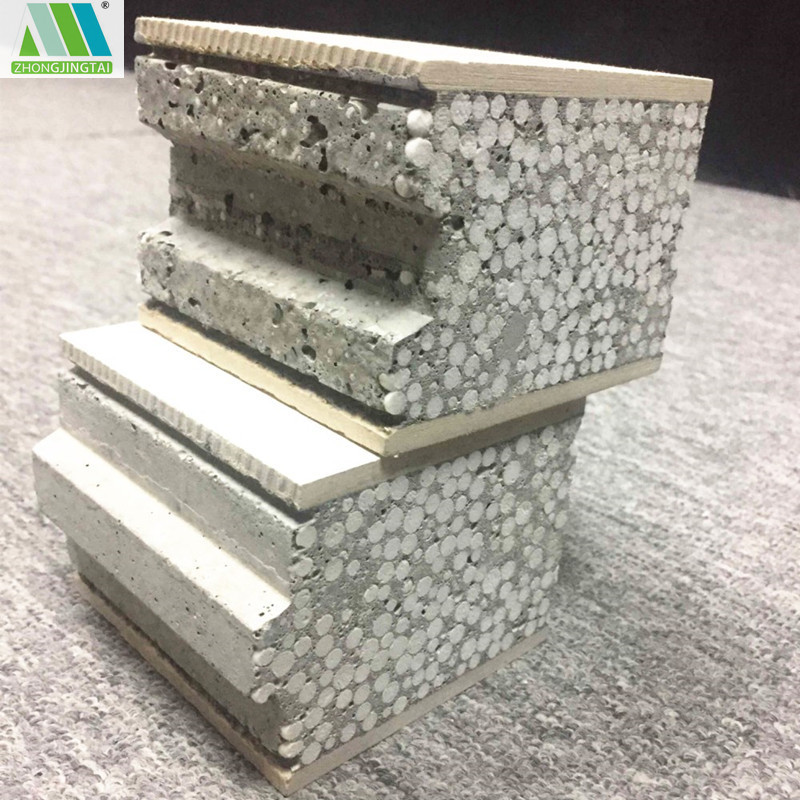

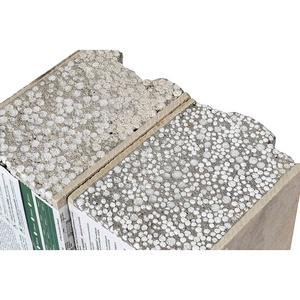

What is Composite EPS Sandwich Cement Wall Panel?

ZJT lightweight energy saving composite eps sandwich cement wall panel is composed of face panel and interior filling. The material of face panel is caIcium siilcate board and the core is composite of sand,cement, eps foam, water, fly ash, t's a new wall panel instead of the traditional bricks during the mordern construction.

Specification

| Length | 2270,2240mm |

| Width | 610mm |

| Thickness | 60mm | 75mm | 90mm | 100mm | 120mm | 150mm |

| Partition | roof | roof | interior wall | interior wall | exterior wall | exterior wall |

| National Standards | Testing Results | ||||||

| S/N | Items | 60mm | 90mm | 120mm | 60mm | 90mm | 120mm |

| 1 |

Anti-impact Capacity/times |

≥5 |

≥5 |

≥5 |

≥8 |

≥10 |

≥15 |

| 2 | Anti-bending damage load/times over deadweight |

≥1.5 |

≥1.5 |

≥1.5 |

≥3 |

≥4 |

≥5 |

| 3 | Anti-pressure(Mpa) |

≥3.5 |

≥3.5 |

≥3.5 |

≥5 |

≥5 |

≥5 |

| 4 | single point hanging strength | ≥1000 |

≥1000 |

≥1000 |

≥1200 |

≥1300 |

≥1500 |

| 5 | Sound insulation capacity in the air (DB) | ≥30 |

≥35 |

≥40 |

≥36 |

≥40 |

≥45 |

| 6 | Fireproof limit/h | ≥1 |

≥1 |

≥1 |

≥4 |

≥4 |

≥4 |

| 7 | Heat transfer coefficient(B/W/M^2.K) | / | / |

≤1.0 |

≤0.1478 |

≤0.1478 | ≤0.1478 |

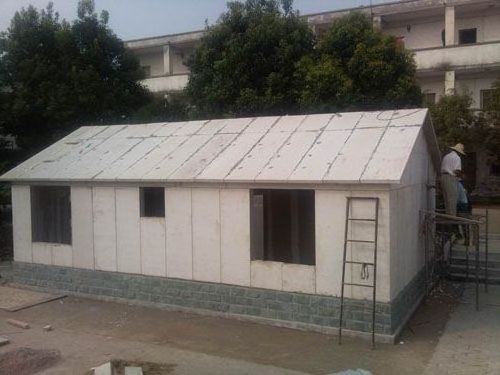

Application:

ZJT wall panel is widely used in the partition of highrise buildings, industrial plants, office buildings,

residential houses, work shed and other constructions. It can be also used as non load bearing structure of washroom, kitchen and renovation of old houses. And it's particularly applicable to places with high fireresistance requirement.

OFFICE BUILDINGS

PREFABRICATED HOUSES

VILLAS

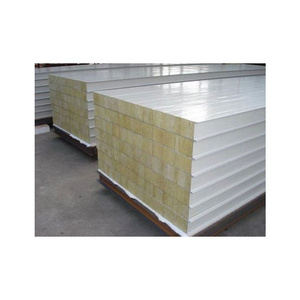

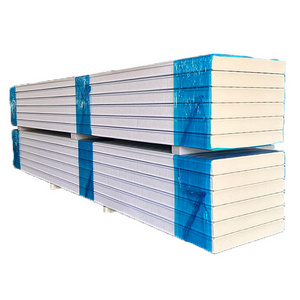

Packing

Free packing: normal pallet + packing belt

Standard exporting packing: good pallet+pearl wool+corner protective paper+packing belt+plastic thin film

Loading: Normally 18 pallets per 20' container or according to clients' requirements

Installation and Accessory Materials

Alignment

:making the base line of the installation position of the wallboard.

↓

Sawing of wallboard

:cutting and adjusting the width and length of wallboard on the basis of the requirement.

↓

Sizing

: blending the ZJT cement mortar and plastering it into the gap and base line bettwen the wallboard.

↓

Fitting the sheet

: moving the mortar-covered wallboard to the right position and using crowbar to ensure the wallboard are tight with another one.

↓

Placing the wallboard

: filling the vacant position of the wall

↓

Adjustment

: fixing the wallboard with wooden wedge, spiking steel bar into the glued wallboard an two steel bars should be spiked beyong 120mm wall board.

↓

Filling joints

: clear away the facial panel cement mortar and press it tightly with round steel bar.

↓

Installation of crack-resistant material:

after about one week, taking out the wooden wedges and paste the anti-crack tape with cement mortar.

↓

Insertion of wires

: do not dig the same place in the two wallboard facial and the deep can't beyond 2/3 of the wallboard.

↓

Plastering paint:

to finish the wal, tiles can be paste without any scraping and wallpaper also can be applied directly.

Accessory Materials

Steel Bar

Anti-crack Tape

Wooden Wedge

Cement Mortar

Electrick Circular Machine