2.SIMPLE OPERATION

3.LARGER DAY OUTPUT

4.STABLE PERFORMANCE

5.

HIGH MECHANIZATION

|

No

|

Item

|

Data

|

|

1

|

Work principle

|

Extrusion technology

|

|

2

|

Day capacity/per unit

|

500-600 m

2

/8 hours

|

|

3

|

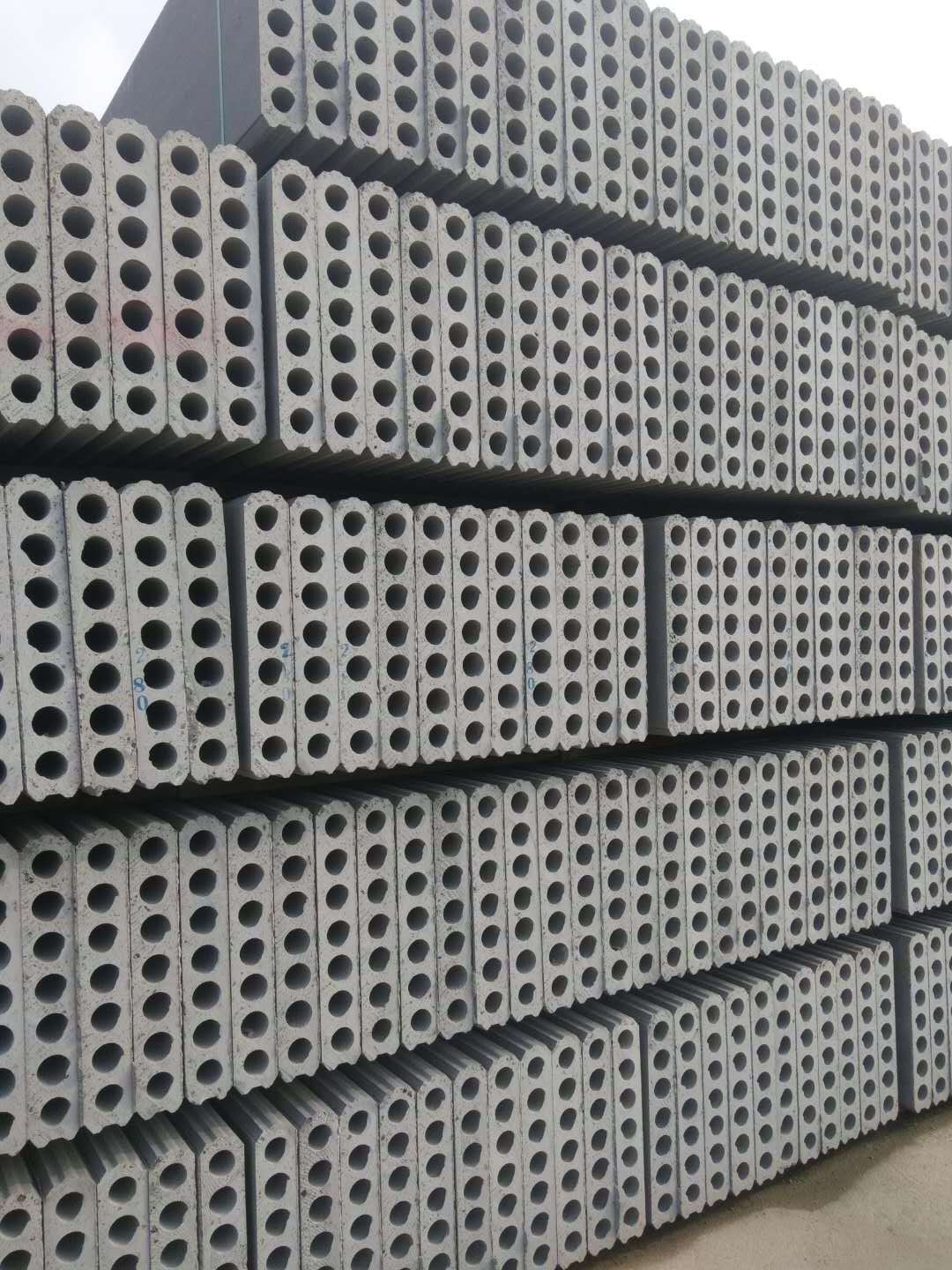

Popular Panel Diamension

|

Thickness 90/100mm*Width 1000mm *Length 3000mm(any size)

|

|

4

|

Vibrating device

|

High frequency or general(Contact us for details)

|

|

5

|

Hole

|

Circular hole

|

|

6

|

Hollow

|

Hollow & solid (by exchange augers)

|

|

7

|

Raw material

|

limestone/sand/stone powder/sawdust/slag/fly ash/tefra/construction waste(any one or more)+cement+water+additive

|

|

8

|

Volume Weight

|

For example: ≤100kg/m

2

for 90mm slag hollow core wall panel

|