- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

CST

-

Core Components:

-

evaporator

-

Weight (KG):

-

500 KG

-

Name:

-

Industrial Air To Water Heat Exchanger 100kw Dry Cooler

-

Operating Voltage:

-

380/400 VAC

-

Tube material:

-

stainless steel, aluminum, hot dip carbon steel

-

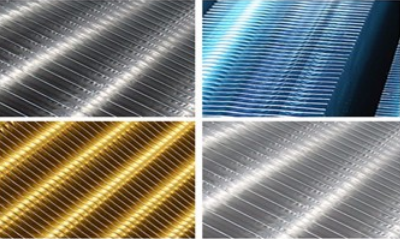

Fin material:

-

Aluminum, stainless steel, hot dip carbon steel

-

Frame material:

-

stainless steel, aluminum, hot dip carbon steel

-

Fin space:

-

2-20mm

-

Application:

-

Gas and oil industry

-

Feature:

-

Corrosion Resistant

-

Package:

-

Wooden Case

Quick Details

-

Type:

-

dry cooler

-

Mounting:

-

Floor Standing

-

Airflow:

-

300m³/h

-

Place of Origin:

-

China

-

Brand Name:

-

CST

-

Core Components:

-

evaporator

-

Weight (KG):

-

500 KG

-

Name:

-

Industrial Air To Water Heat Exchanger 100kw Dry Cooler

-

Operating Voltage:

-

380/400 VAC

-

Tube material:

-

stainless steel, aluminum, hot dip carbon steel

-

Fin material:

-

Aluminum, stainless steel, hot dip carbon steel

-

Frame material:

-

stainless steel, aluminum, hot dip carbon steel

-

Fin space:

-

2-20mm

-

Application:

-

Gas and oil industry

-

Feature:

-

Corrosion Resistant

-

Package:

-

Wooden Case

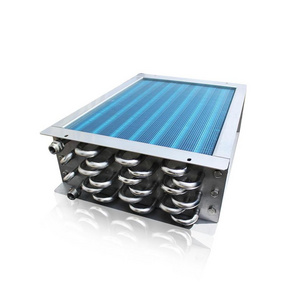

Tube fin dry air coolers

EC variable speed fan motor-- save lot of energy

ZAplus/ Axi Top for greater volume flow and extreme silence

Adiabatic system significantly reduce energy consumption in summer

Epoxy coated or Hydrophilic aluminum fin suitable for coastal or high corrosion area

Fluid dry cooler

Clean stainless steel tube and aluminum fin coil for cooling deionized water

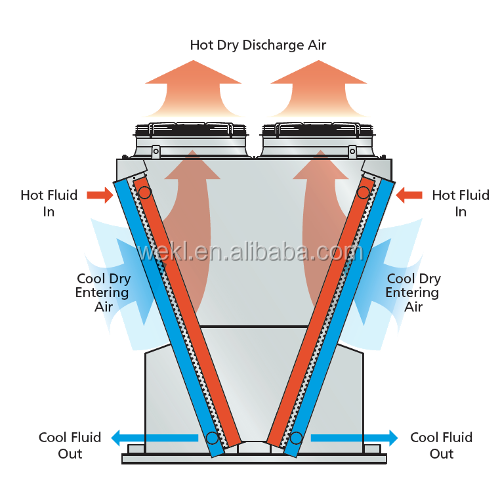

Principle of Operation:

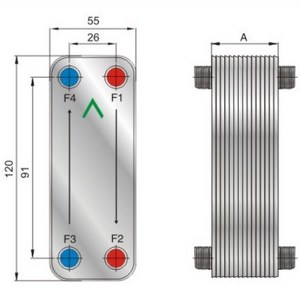

Fins

• Copper

• Stainless steel

• Hot deep carbon steel

• Titanium

Tubes

Frame and Casing

We also supply aluminum, stainless steel cabinet and casing

One Immersion Cooling Solution is Dry Cooler direct cooling.

Summer: dry cooler cools the refrigerant through a plate exchanger or shell and tube heat exchanger.

Winter: dry cooler replaces chiller, directly supplies cooling source to the air cooler, cools the room

specializes in researching, manufacturing and exporting Heat Exchangers, Evaporators, Condensers, air cooler and other heat transfer equipments for the varied industries since 2004

Professional Skills

PRE-SALES SERVICE

* 24 hours oneline inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* After advance payment, we will provide the production drawing to the customer for confirmation

* Engineers available to service machinery overseas.

Q1: What is your strength ?

A: Design and manufacture.

Q2: How long is your delivery time?

A:Different products' production time is different. Generally, it needs 10 to 40 working days.

Q3: What is your terms of payment ?

A:50% TT deposit in advance, 50% TT balance before delivery.

We provide Alibaba Trade Assurance Service. Welcome for more advise.

Q4: Any other products except dry cooler ?

A: Yes.

Our 3 main products are: Condenser and Evapotator, Industrial air cooler and Unit cooler and Coil.

Q5. How to contact with you ?

A: 24hours online from TradeManager, quick answer, or email with us, wechat, skype, whatsapp is available.

Select one product and leave message to us.