- Product Details

- {{item.text}}

Quick Details

-

Material:

-

SMC (sheet molding Compound )

-

Loading Class:

-

EN124 D400

-

Clear Opening:

-

300-900mm

-

Height:

-

50-100mm

-

Waterproof:

-

Double EPDM Rubber Sealing

-

Lifting Holes:

-

aluminum alloy

-

Application:

-

Fuel Station / Main Road

-

Weight:

-

Super-Lightweight Design

-

Surface Design:

-

Anti-slip design

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

JQ

-

Product name:

-

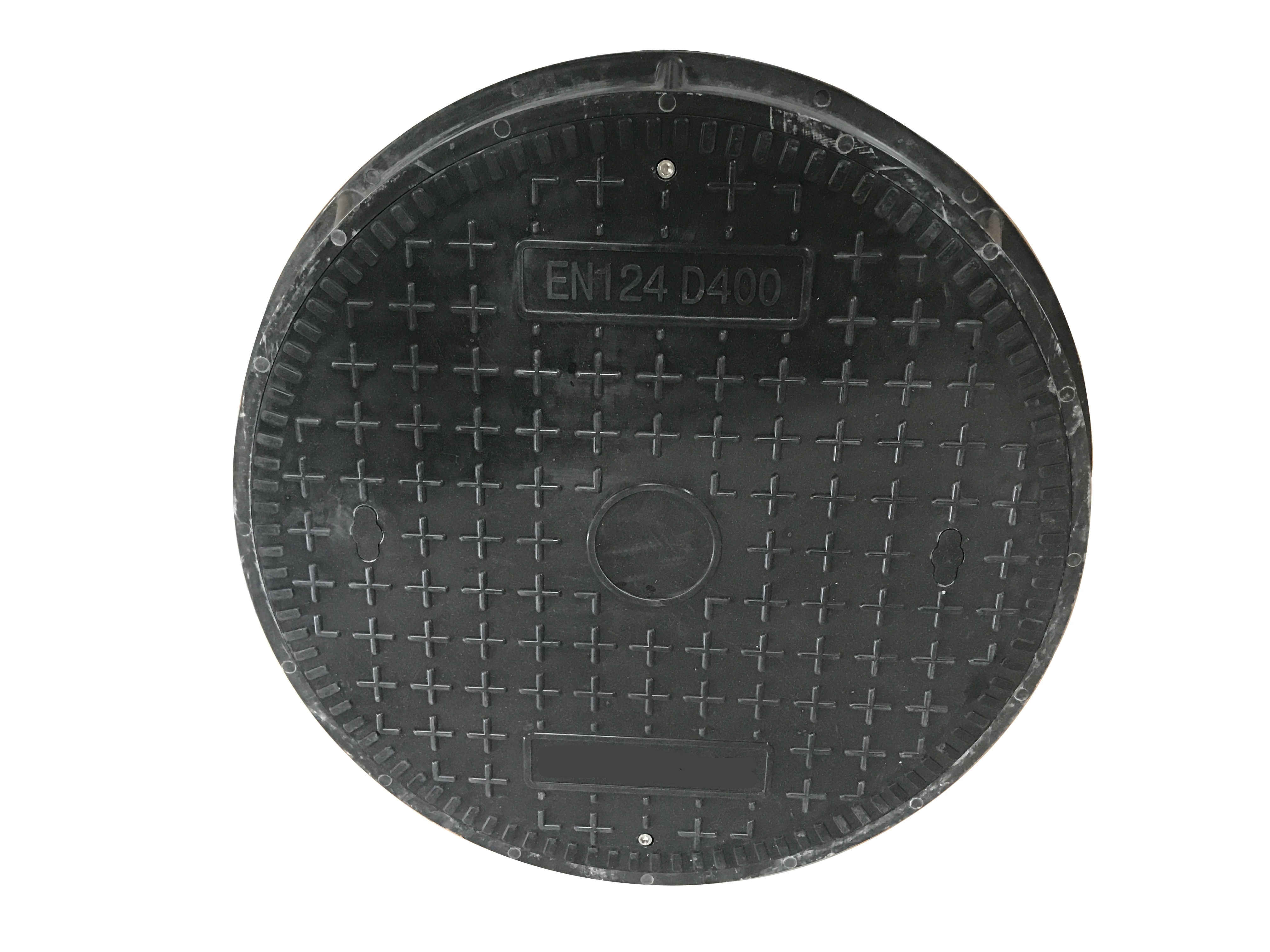

SMC Manhole Cover

-

Material:

-

SMC (sheet molding Compound )

-

Loading Class:

-

EN124 D400

-

Clear Opening:

-

300-900mm

-

Height:

-

50-100mm

-

Waterproof:

-

Double EPDM Rubber Sealing

-

Lifting Holes:

-

aluminum alloy

-

Application:

-

Fuel Station / Main Road

-

Weight:

-

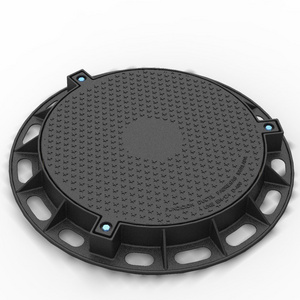

Super-Lightweight Design

-

Surface Design:

-

Anti-slip design

Product Description

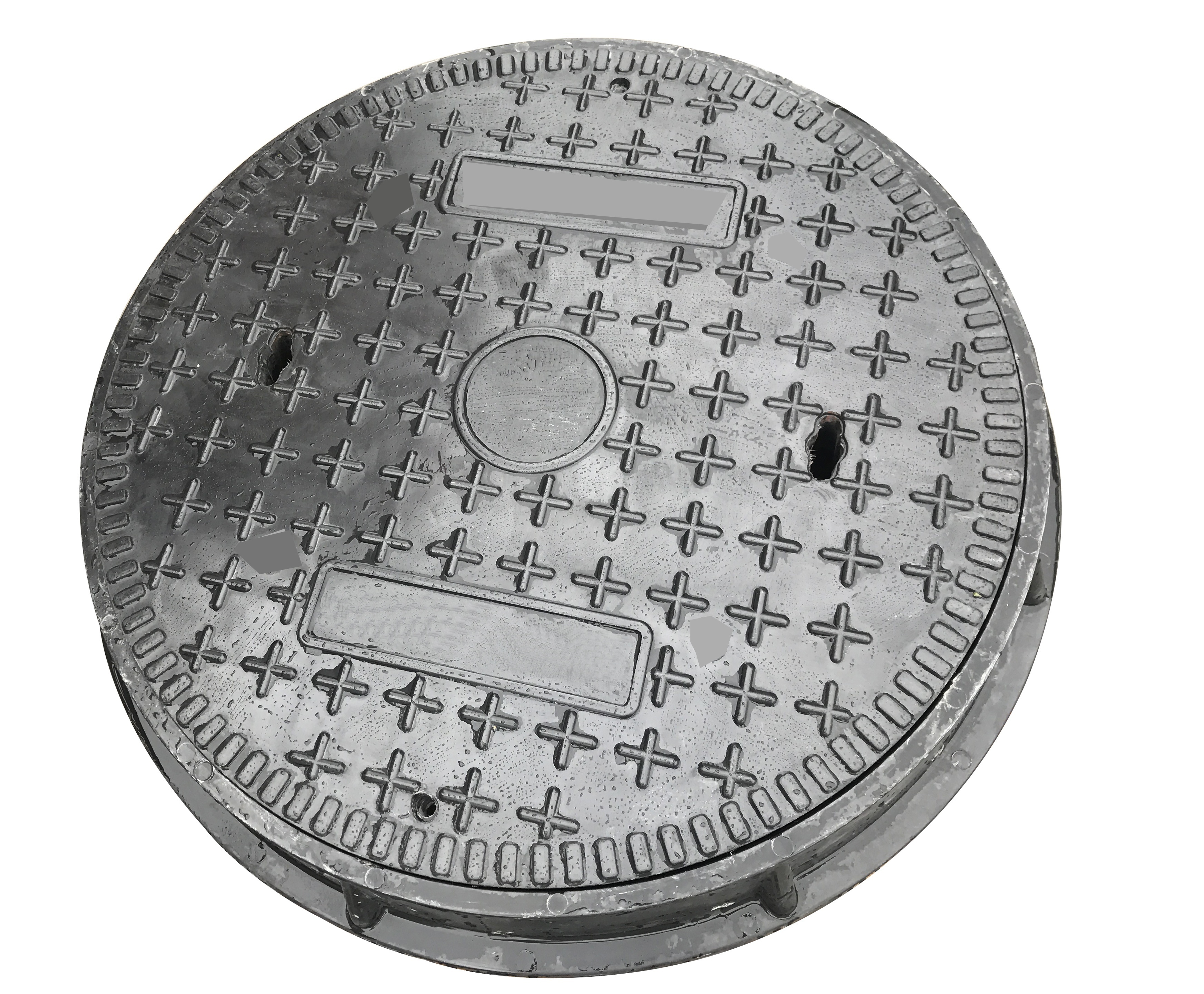

Sealing EN124 Heavy Duty Composite Manhole Cover

Core advantages :

1, E

xcellent

Lightweight design , from

Structural design + Material Composition +

Fusion method .

2,100% Waterproof ,

unique

rubber hollow design , EPDM material .

Double sealing ring in cover and frame .

3 , Lifting hole :

Aluminum alloy , easy installed and long service life .

4, Unti-slip sruface design ,

5, UV-resistance ,

Exclusive recipe , no fade more than 3 year .

The world's first technology to solve the fading problem of SMC products .

6, Competitive prices .

7, Accepted ODM and OEM .

|

Product Name

|

SMC Manhole Cover

|

Material

|

SMC

|

|

Size

|

Clear Opening 600mm

|

Loading Class

|

EN124 D400 C250

|

|

Rubber Material

|

EPDM

|

Waterproof

|

Yes

|

|

Production Tech

|

Molding

|

Modes of packing

|

Packed in three cartons

|

|

Work Temperatures

|

-50 ℃ - +150℃

|

Seivice Life

|

>25 YEARS

|

Detailed Images

Material Description

Double EPDM rubber design

Special shape for in and our easy

Great waterproof effect

EPDM Rubber Sealing

Hollow design

Special lifting Hole

Manufacturing Technique

Workshop Show

SMC Machines

Factory have two sets SMC machines , now have production value about 30 Tons / days

Loading Test Machines

All Manhoel Cover orders will taken QC testing .1, Each order / Each batch first products testing .

2, Each batch material chaging first product testing .

3,Workers Chaing first samples testing .

4, QC inregular Testing .

2, Each batch material chaging first product testing .

3,Workers Chaing first samples testing .

4, QC inregular Testing .

Samples Room

Samples Room

Hot Searches