- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380v

-

Power:

-

30-45Kw

-

Dimension(L*W*H):

-

10000*1200*1800mm

-

Application fields:

-

Food/Supplement

-

Machinery Capacity:

-

150/300/450/600kg/h

-

Machinery Function:

-

Candy/Gummy Making

-

Raw material:

-

Sugar, newtol, gelatin, pectin, etc

-

Showroom Location:

-

Other

-

Application / Usage:

-

Gummies production for food & supplement

-

Product name:

-

Candy Mahcine

-

Material:

-

SUS304/316L Stainless Steel

-

Processing Types:

-

Depositing Machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Power Source:

-

Eletric

-

Heat Source:

-

Eletric, Steam

-

Advantage:

-

Easy Operation and cleaning

-

Candy/Gummy shapes:

-

Customized

-

Cooling tunnel:

-

Air Conditioner

Quick Details

-

Model Number:

-

SNGB

-

Brand Name:

-

DARUITEK

-

Place of Origin:

-

China

-

Voltage:

-

220/380v

-

Power:

-

30-45Kw

-

Dimension(L*W*H):

-

10000*1200*1800mm

-

Application fields:

-

Food/Supplement

-

Machinery Capacity:

-

150/300/450/600kg/h

-

Machinery Function:

-

Candy/Gummy Making

-

Raw material:

-

Sugar, newtol, gelatin, pectin, etc

-

Showroom Location:

-

Other

-

Application / Usage:

-

Gummies production for food & supplement

-

Product name:

-

Candy Mahcine

-

Material:

-

SUS304/316L Stainless Steel

-

Processing Types:

-

Depositing Machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Power Source:

-

Eletric

-

Heat Source:

-

Eletric, Steam

-

Advantage:

-

Easy Operation and cleaning

-

Candy/Gummy shapes:

-

Customized

-

Cooling tunnel:

-

Air Conditioner

Product Description

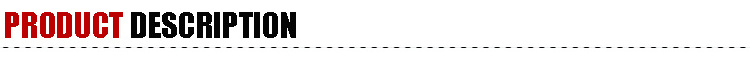

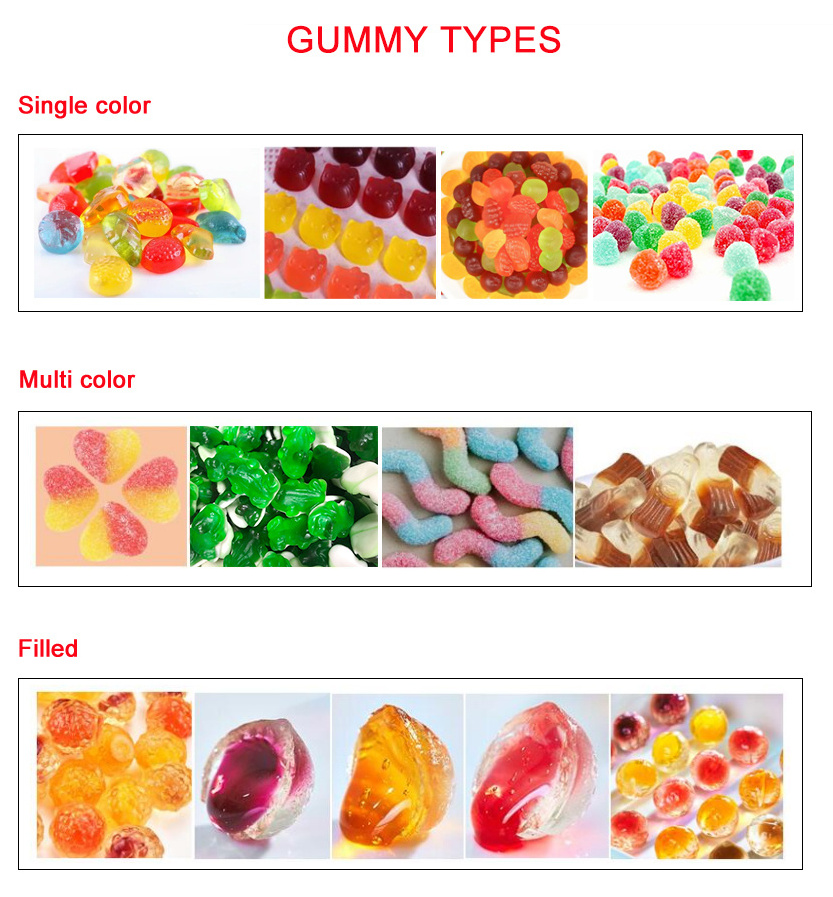

The SNGB series fully automatic gummy/candy making production line is specially designed for medium-small scale experimental production. The machine is the most advanced pouring molding structure design in the market, which is easy for workers to operate and maintain. The series of production line is mainly suitable for small batch production. All materials and structures of the whole set of equipment have been strictly tested before leaving the factory, and the market feedback of the equipment is good. It is suitable for the nutrition, food, and supplement industries.

Application

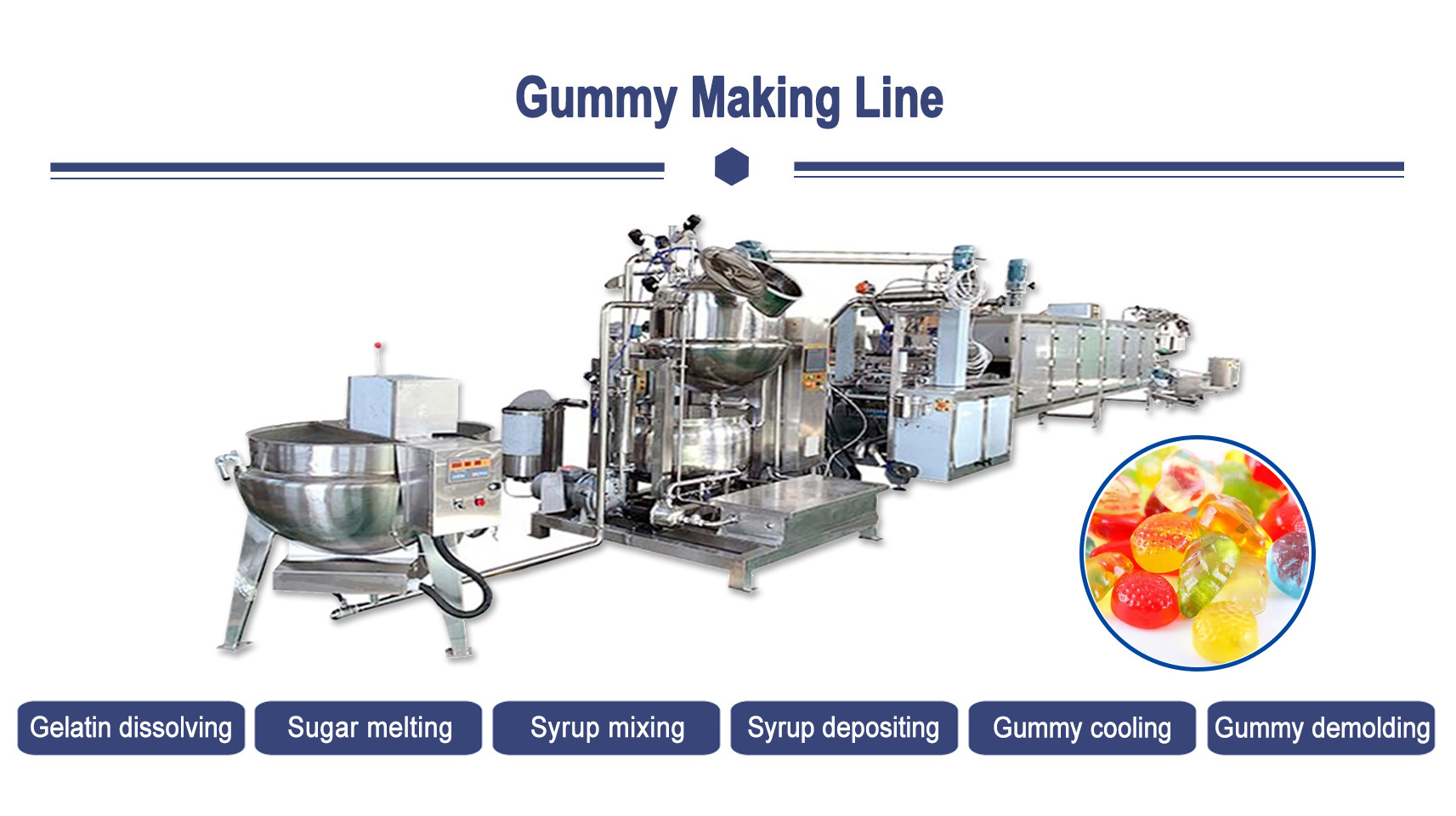

* The main depositing machine can be used for various types gummies, hard candy and

lollipop production,

just need to replace the molds with different shapes.

* The syrup dissoliving process of hard candy and gummy is different and requires different equipment to produce.

Specification

|

Items

|

Parameters

|

|

Model

|

SNGB-150 Fully automatic gummy making line

|

|

Production capacity

|

150 kg/hour

|

|

Depositing head

|

10/20 head (Depend on single or multi color)

|

|

Depositing times

|

20-45 n/min

|

|

Power supply

|

3phase, 380/220V, 50/60Hz

|

|

Control mode

|

PLC & Touch screen

|

|

Depositing mode

|

Servo motor

|

|

Cooling mode

|

Air conditioner

|

|

Dimension

(Only depositing and cooling machine)

|

10000×1200×1800mm

|

|

Material of machine

|

Stainless steel 304 / 316L

|

Details Images

The syrup is pumped into the hopper of the depositing machine through the insulated stainless steel pipe.

The whole process is controlled by PLC, without manual operation. Working stable.

Double insulation hopper can prevent the syrup from solidifying, suitable for the production of various multi-color gummies.

Cooling tunnel adopts Denmark

Danfoss

brand air conditioning high-power compressor, three-layer cooling structure, fast shaping, non-stick mold.

Gummy mold is made of high quality food grade thickened aluminum alloy material, and the surface is sprayed with

polytetrafluoroethylene anti-stick coating. Long service life, corrosion resistance.

polytetrafluoroethylene anti-stick coating. Long service life, corrosion resistance.

Recommend Products

Packing & Delivery

Hot Searches