- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5300*5630*1750mm

-

Power (kW):

-

20KW

-

Weight (KG):

-

4500 kg

-

Feed Rate:

-

12-23m/min

-

Working Pressure:

-

0.8Mpa

-

Sheet Thickness:

-

10-60nm

-

Total Power:

-

16.5kw

-

Edge Thickness:

-

0.4-3mm

-

Overall Size:

-

8350x1000x1600mm

-

Sheet Width:

-

≥80mm

-

Net Weight:

-

2700kg

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Factory brand

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5300*5630*1750mm

-

Power (kW):

-

20KW

-

Weight (KG):

-

4500 kg

-

Feed Rate:

-

12-23m/min

-

Working Pressure:

-

0.8Mpa

-

Sheet Thickness:

-

10-60nm

-

Total Power:

-

16.5kw

-

Edge Thickness:

-

0.4-3mm

-

Overall Size:

-

8350x1000x1600mm

-

Sheet Width:

-

≥80mm

-

Net Weight:

-

2700kg

Product Description

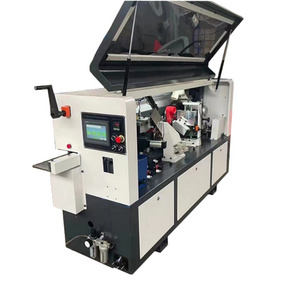

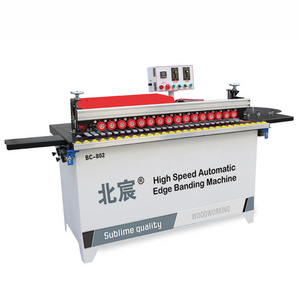

JLF380A-AGH

Product real shot and details

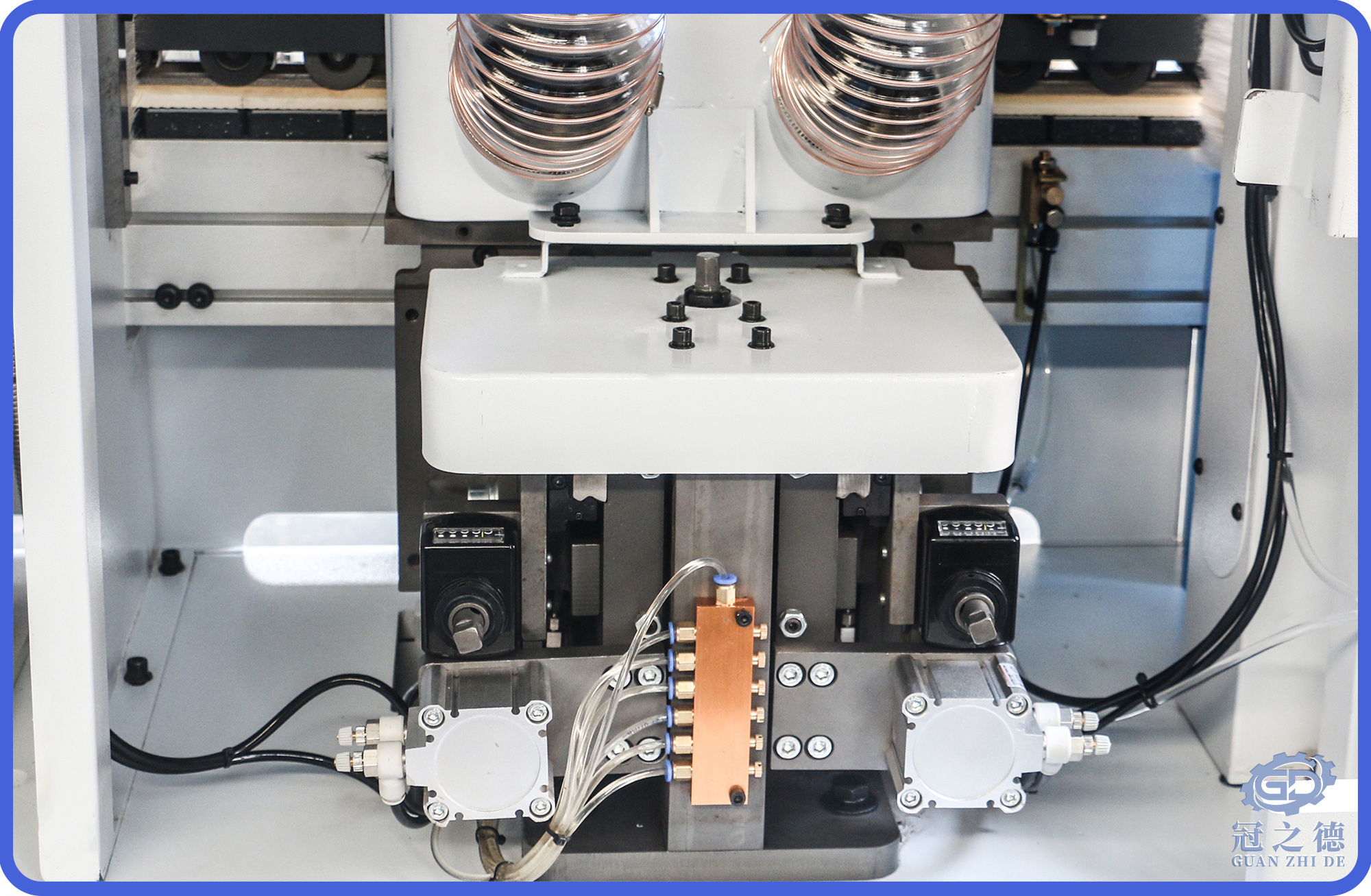

PRESSURE UP DEVICE

Aluminum alloy profile press beam, electronic height adjustment, asynchronous motor drive, mechanical digital positioning display.

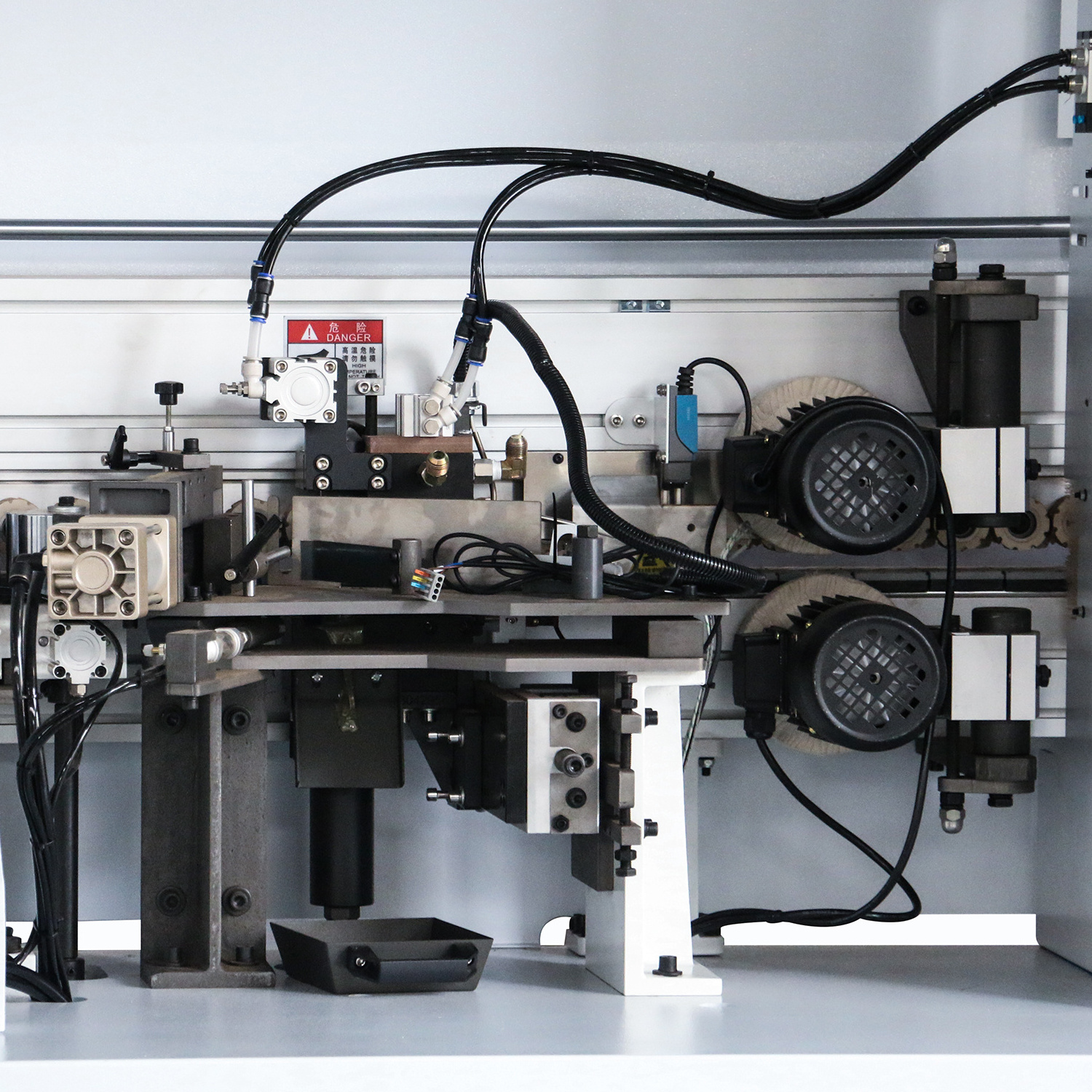

SEPARATING AGENT DEVICE

To prevent adhesion between two identical or different plates

DOUBLE CUTTER HEAVY PRE MILLING FUNCTION

(standard 35mm diamond pre milling cutter)

Pneumatic front and rear feed, dual independent milling thickness adjustment function, with independent backup gear, standard equipped with 2 * 2.2KW high-frequency high-speed motor up to 12000 rpm

SIX WHEEL PRESS STICK

One main wheel, with a diameter of 100mm, and five driven wheels at the rear, to ensure a firm fit between the edge banding belt and the plate

INFRARED BAKING LAMP DEVICE

The contactless infrared heating lamp device is designed to accommodate the differences between the south and the north. Due to the cold weather in the north in winter, the peeling of the edge banding belt has become a major puzzle for edge banding machines.It can instantly heat the plate, greatly improving the adhesion between the glue and the edge banding belt, preventing the edge banding belt from falling off

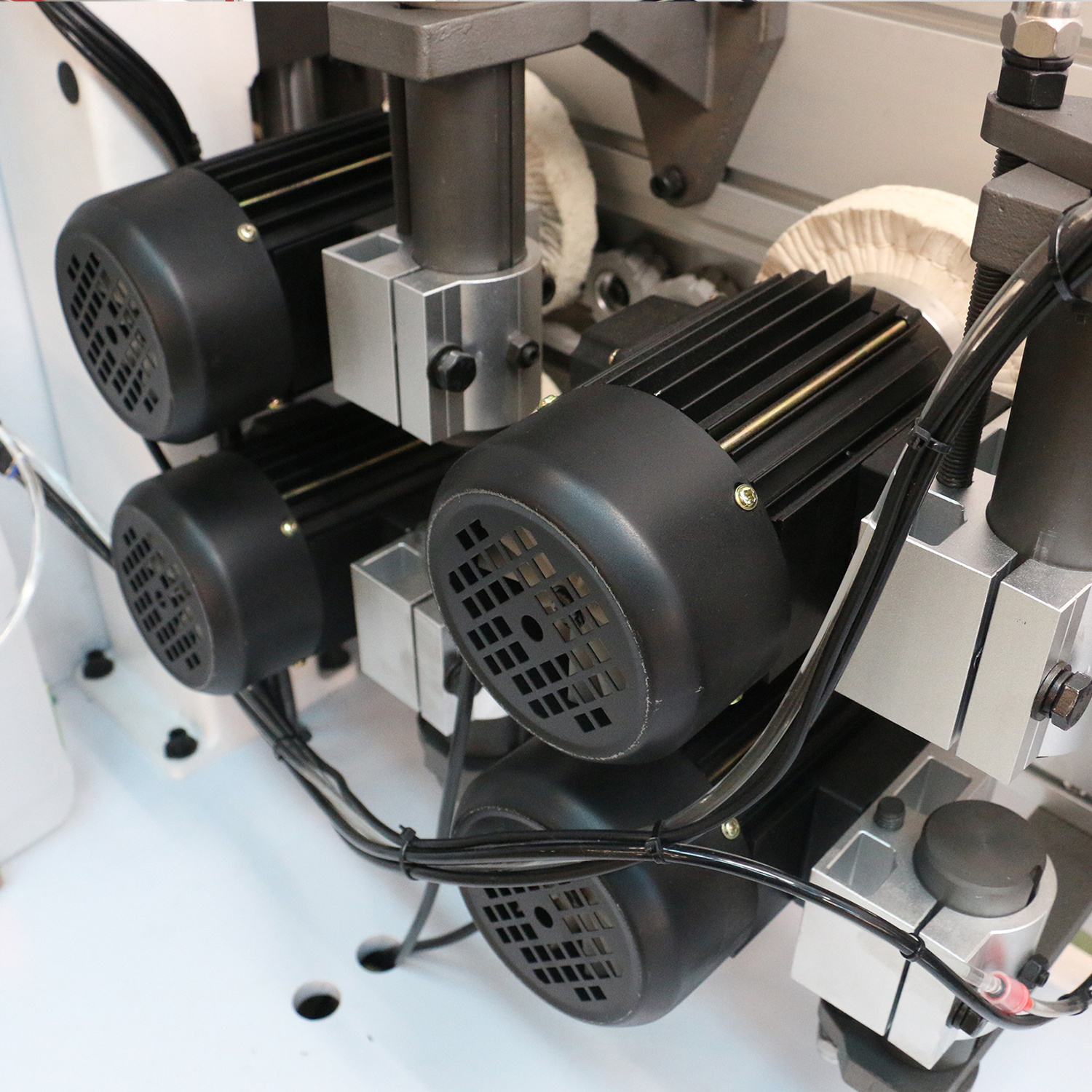

HEAD AND TAIL TRIMMING FUNCTION

Two motors, each with a power of 0.37KW, a frequency of 200hz, and a rotational speed of 12000 rpm/minAdopt a unique working air pressure and start-up lifting air pressure separation mode to ensure the stability of head trimming

TRIMMING FUNCTION

During edge banding, the high-frequency high-speed motor structure is used to trim the excess edge banding strips on the edge banding plate, so that the width of the edge banding strip is consistent with the width of the edge banding plate, and the motor angle is adjusted;Equipped with independent vacuum hood.Two motors each with a power of 0.75k

UP AND DOWN TRACKING FUNCTION

The four corners of the edge banding belt bonded to the plate are milled into an R-arc shape using a profiling wheel movable left and right profiling rounding device.

EDGE SCRAPING UNIT

(trimming wavy knife marks)

The trimming knives on both sides of the plate scrape away the wavy knife marks caused by the trimming knife on the edge banding belt, making the size of the modified R angle the same as that of the finely trimmed R angle. Make the upper and lower parts of the plate more smooth and tidy.

FLAT SCRAPING DEVICE

Remove excess hot melt adhesive from the workpiece plate surface

POLISHING DEVICE

Used for polishing the longitudinal edge of the workpiece;Clean the edges of the workpiece and remove excess glue.

CLEANING DEVICE

No manual cleaning is required to remove dust and residual glue, and to keep the panel clean and free of traces.

Specification

|

Feed Rate

|

12-23m/min

|

Working Pressure

|

0.6MPa

|

|

Sheet Thickness

|

10-60mm

|

Total Power

|

16.5kw

|

|

Edge Thickness

|

0.4-3mm

|

Sheet Width

|

≥80mm

|

|

Overall Size

|

8350x1000x1600mm

|

Net Weight

|

2700kg

|

|

Track Trimmed Sheet Thickness

|

10-45mm

|

|

|

Hot Searches