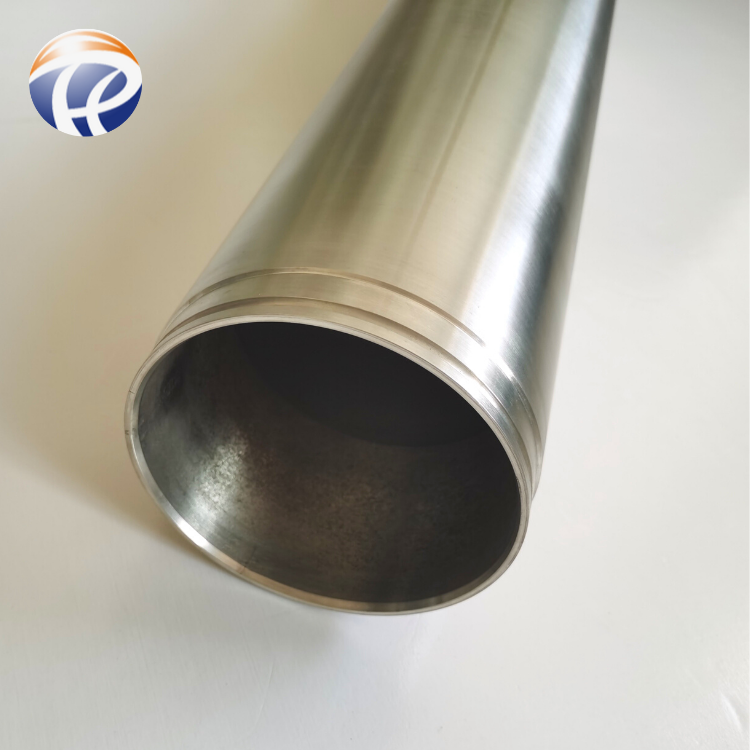

Outside Diameter: 147mm

Inside Diameter: 125mm

Wall Thickness: 604mm

Electrical resistivity:

10³

µOhmcm

Initial permeability:

1.0100

Shear strength:

420 - 570 MPa

Tensile strength:

600.00 - 1200.00

MPa

Density:

8.420

g/cm⁻³

Melting point:

1370.00 - 1425.00

°C

Thermal conductivity: 14.80W m⁻¹ K⁻¹