- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-80mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DA PENG LASER

-

Weight (KG):

-

5600 KG

-

Product name:

-

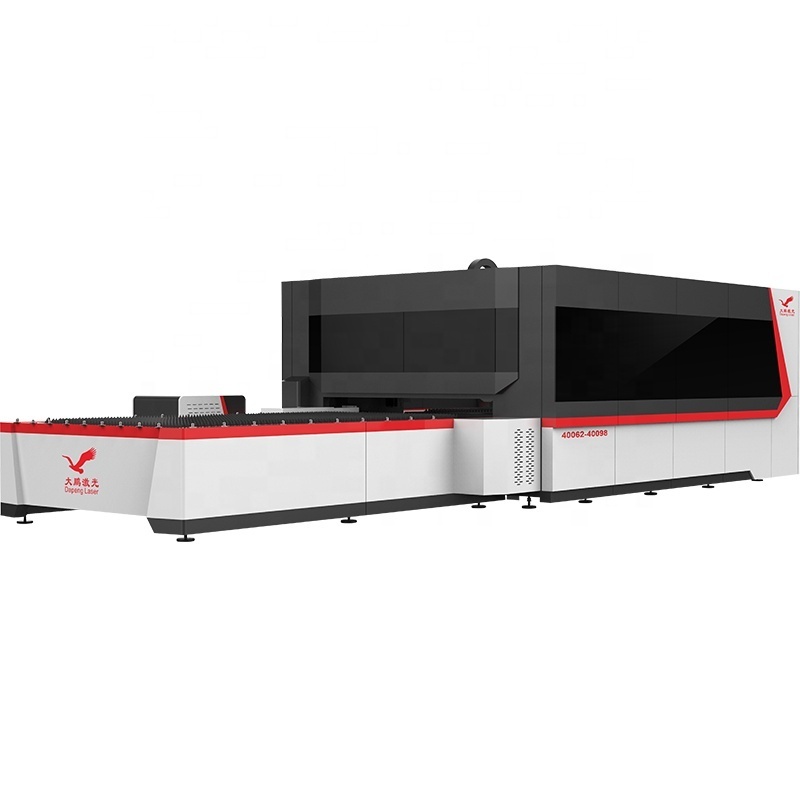

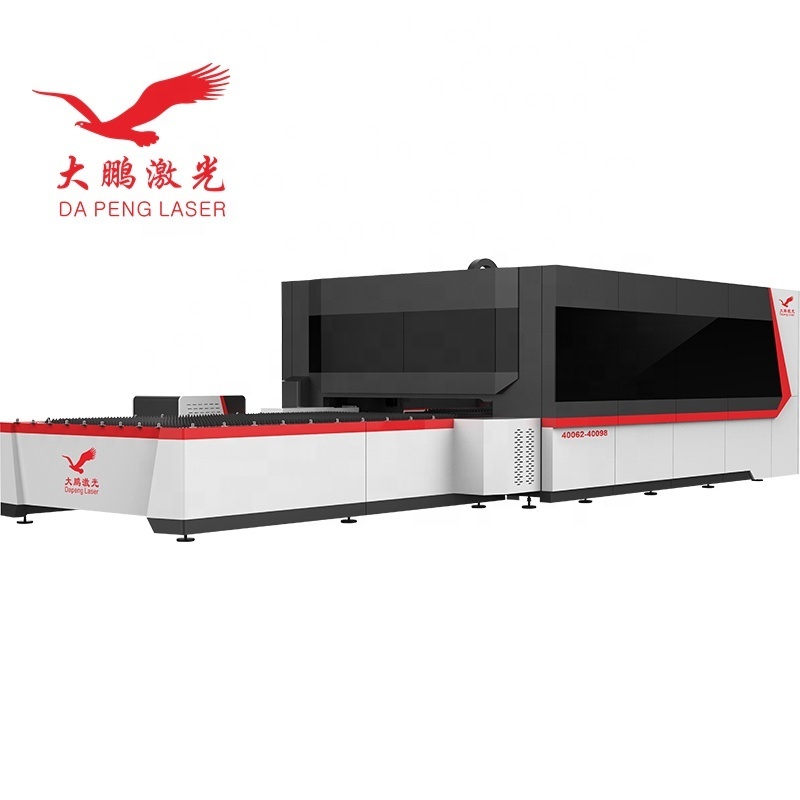

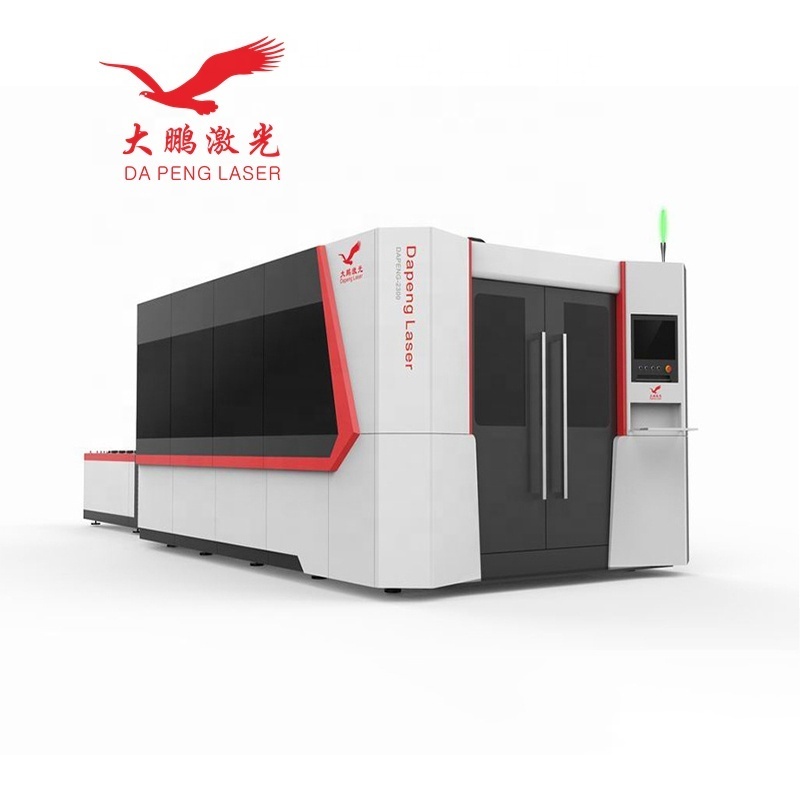

Enclosed Fiber Laser Cutter

-

Laser source type:

-

Fiber source

-

Cutting materials:

-

Stainless Steel Carbon Steel

-

Laser output power:

-

1500W/2000W/3000W

-

Cutting range:

-

3000*1500mm

-

Minimum line width:

-

<0.1mm

-

Cooling method:

-

Water cooling

-

X/Y Positioning Accuracy:

-

0.03mm

-

Transfer method:

-

Precision rack dual drive

-

Keywords:

-

CNC Laser Cutting Machine

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

140m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-80mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DA PENG LASER

-

Weight (KG):

-

5600 KG

-

Product name:

-

Enclosed Fiber Laser Cutter

-

Laser source type:

-

Fiber source

-

Cutting materials:

-

Stainless Steel Carbon Steel

-

Laser output power:

-

1500W/2000W/3000W

-

Cutting range:

-

3000*1500mm

-

Minimum line width:

-

<0.1mm

-

Cooling method:

-

Water cooling

-

X/Y Positioning Accuracy:

-

0.03mm

-

Transfer method:

-

Precision rack dual drive

-

Keywords:

-

CNC Laser Cutting Machine

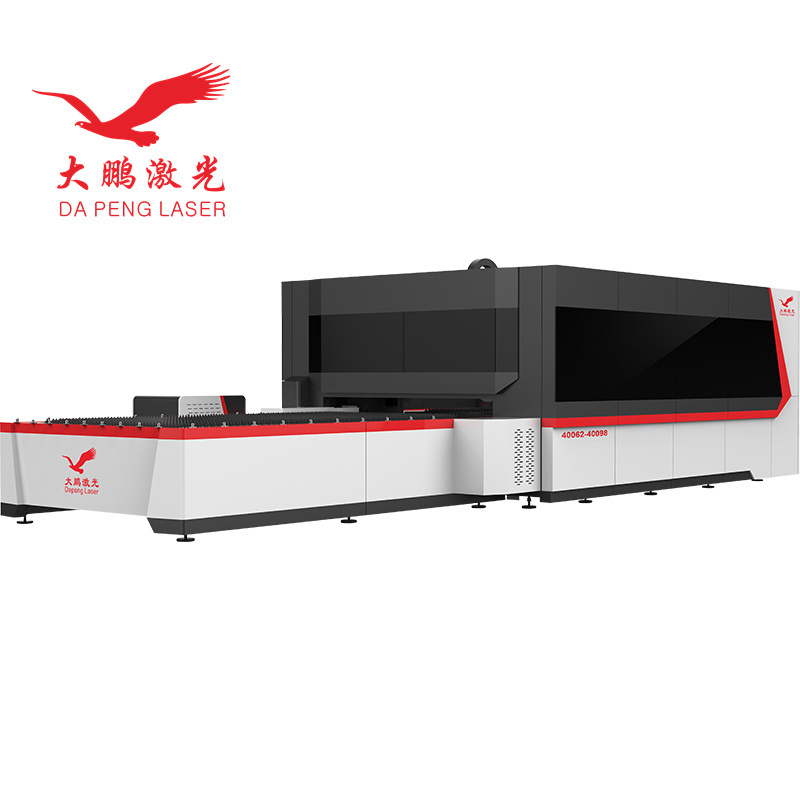

Product Description

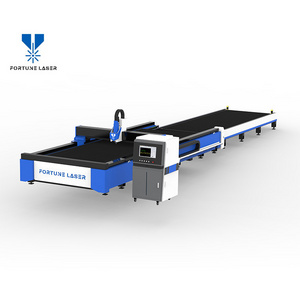

Dapeng Automatic Feed Exchange Platform 1500W 2000W 3000W 6000W Metal Stainless Steel Fiber CNC Laser Cutter Machine

Specification

|

Model

|

DPE-FT3015D-F1500W/F2000W/F3000W

|

|

Laser source type

|

Fiber source

|

|

Laser Out Power

|

1070nm

|

|

Laser wavelength

|

1000W/2000W/3000W/6000W

|

|

Cutting range

|

3000×1500mm

|

|

Minimum line width

|

<0.1mm

|

|

Transfer method

|

Precision rack dual drive

|

|

Cutting speed and thickness

|

Depending on specific material

|

|

Repeatability

|

±0.02mm

|

|

Machine operating temperature

|

0~40℃

|

|

Electricity demand

|

380V/50Hz

|

|

Cooling method

|

Water cooling

|

|

Continuous operating time

|

24 hours

|

|

Weight

|

5600KG

|

|

Dimensions

|

8350x3050x2100mm

|

|

Maximum operating speed

|

120m/min

|

|

Maximum acceleration

|

0.9G

|

|

X/Ypositioning accuracy

|

1.2mm

|

|

Minimum slit width

|

0.15mm

|

Features:

Product Features

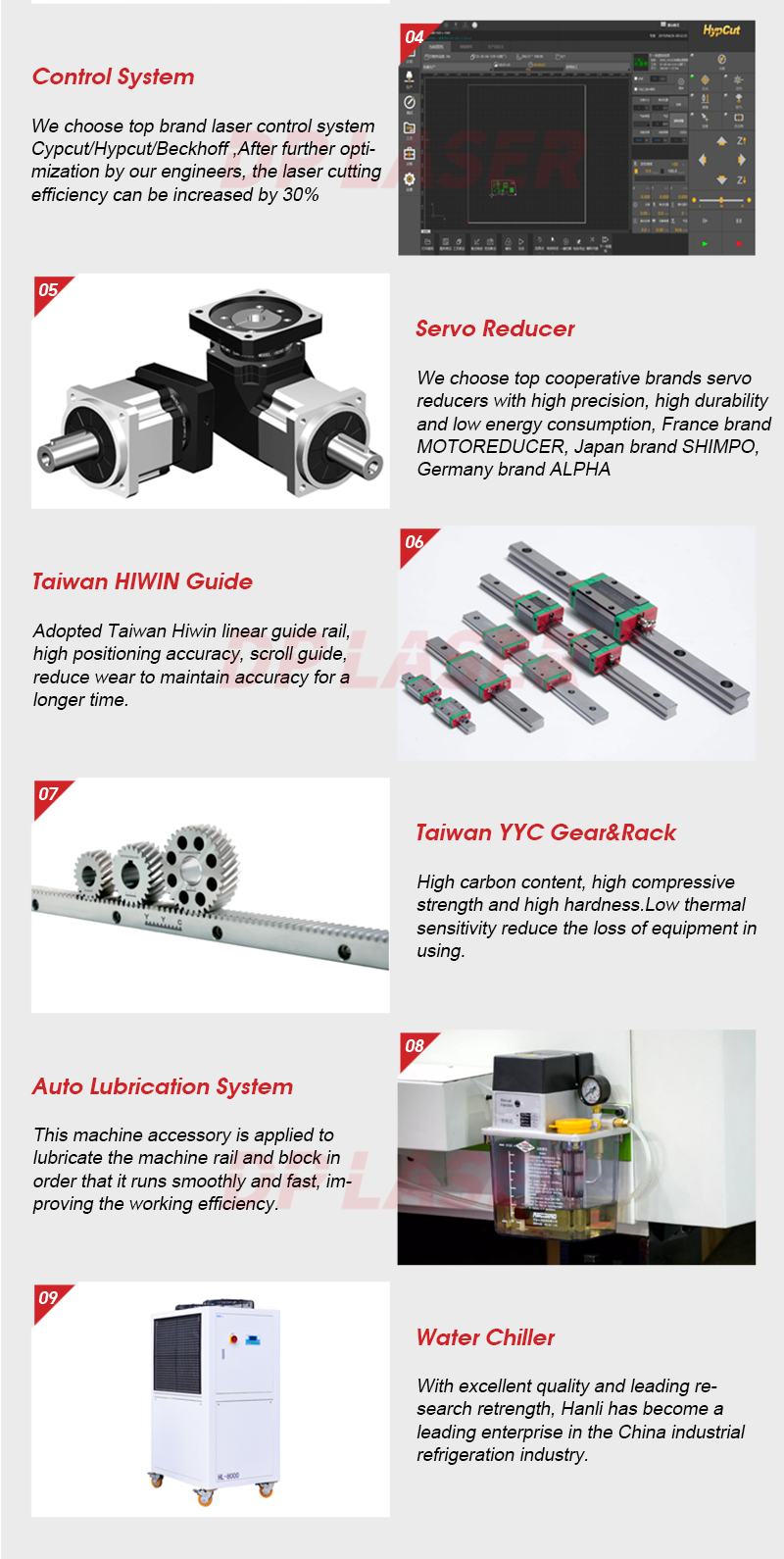

1,Gantry double drive structure, smooth and reliable movement.

2,Thickened heavy machine bed and worktable, no deformation for 20 years, greatly extending the service life of the machine.

3,Precision gear rack drive, with high response and high precision servo motor.

4,The international first-class quality of fiber laser, industrial application for many years, long service life, maintenance free, stable and reliable.

5,High precision laser cutting head, imported optical lenses, is focused on the fine, the adjustment is convenient, cutting perfect.

6,A double closed-loop control capacitive height controller, low requirement to the steel sheet, cutting quality is stable and reliable.

7,CNC system is concise and easy operation, low requirements for the operator.

8,Cutting graphic input multiple formats, powerful draw and edit graphics function.

9,China top professional laser cutting software, cutting technology experts, data call functions.

Advantages

* Using Germany IPG laser source, the electro-optical conversion efficiency is high, which can save power consumption during work and save operating cost.

* The design of the dual platform, when one workbench is cutting, the other workbench can simultaneously work on the loading and unloading to improve work efficiency.

* The focal length of the cutting head can be self-adjusted following the surface height of the material, even if the surface of the material is not flat, the cutting quality can be guaranteed.

* Equipped with a handheld controller, you can manually control the cutting position

* With precision ball screw, rack and pinion, linear guide transmission operation, thus achieving high precision, high efficiency and stability of the machine tool.

* The switch of the solenoid valve and the proportional valve is controlled by the system. The input value in the numerical control system can control the size of the proportional valve outlet, without manual adjustment.

* High-strength integrated welding fuselage and aerospace-grade aluminum alloy beams are subjected to high-temperature annealing to ensure long-term use without deformation.

Applications

1. Application Industries: Widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

2. Application Materials: Suitable for metal cutting with Stainless Steel Sheet, Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Iron Plate, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Metal Sheet,Metal Plate, Tubes and Pipes, etc.

Click here to contact us for more information

Hot Searches