- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zhong Run

-

Color:

-

White

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

China

-

Model Number:

-

00

-

Brand Name:

-

Zhong Run

-

Color:

-

White

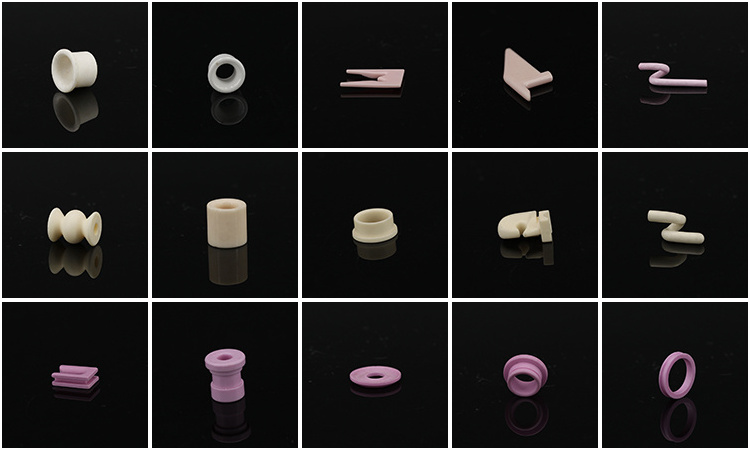

| textile ceramic parts | ||

|---|---|---|

• All items According to client's drawing

| Product Description |

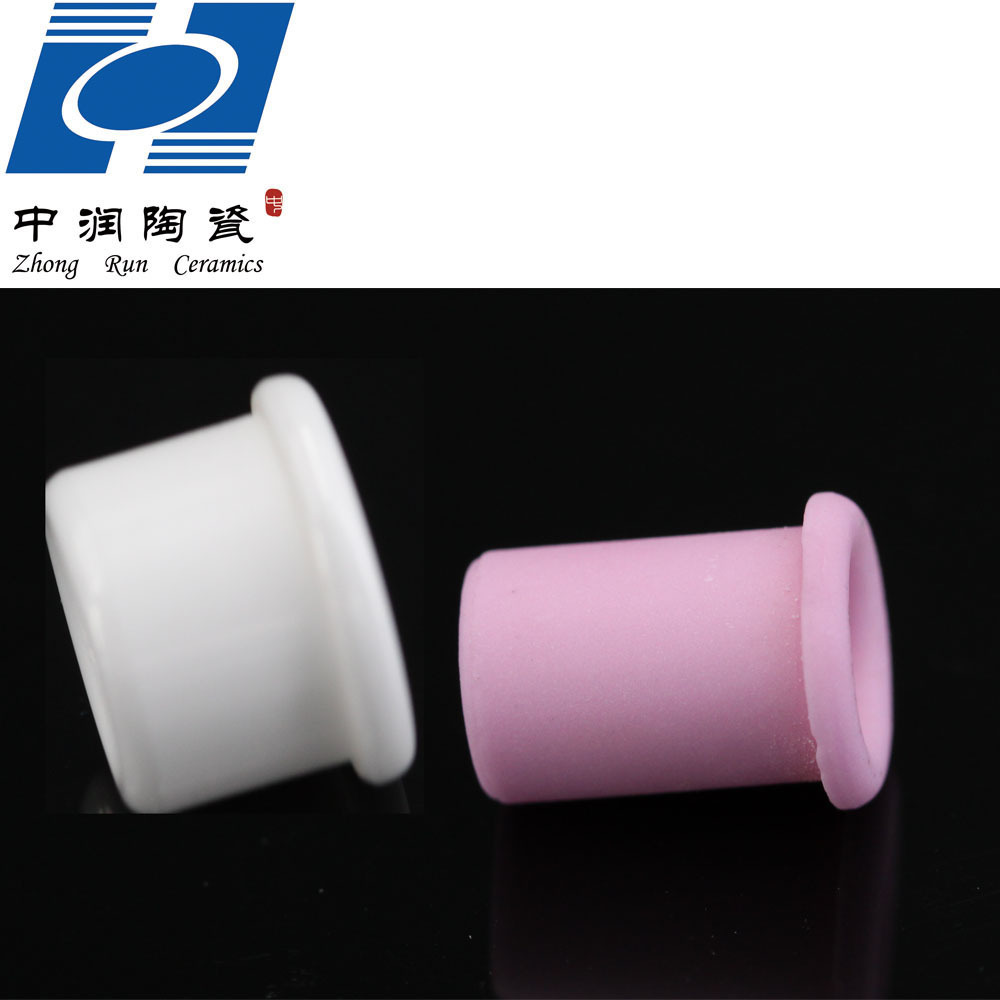

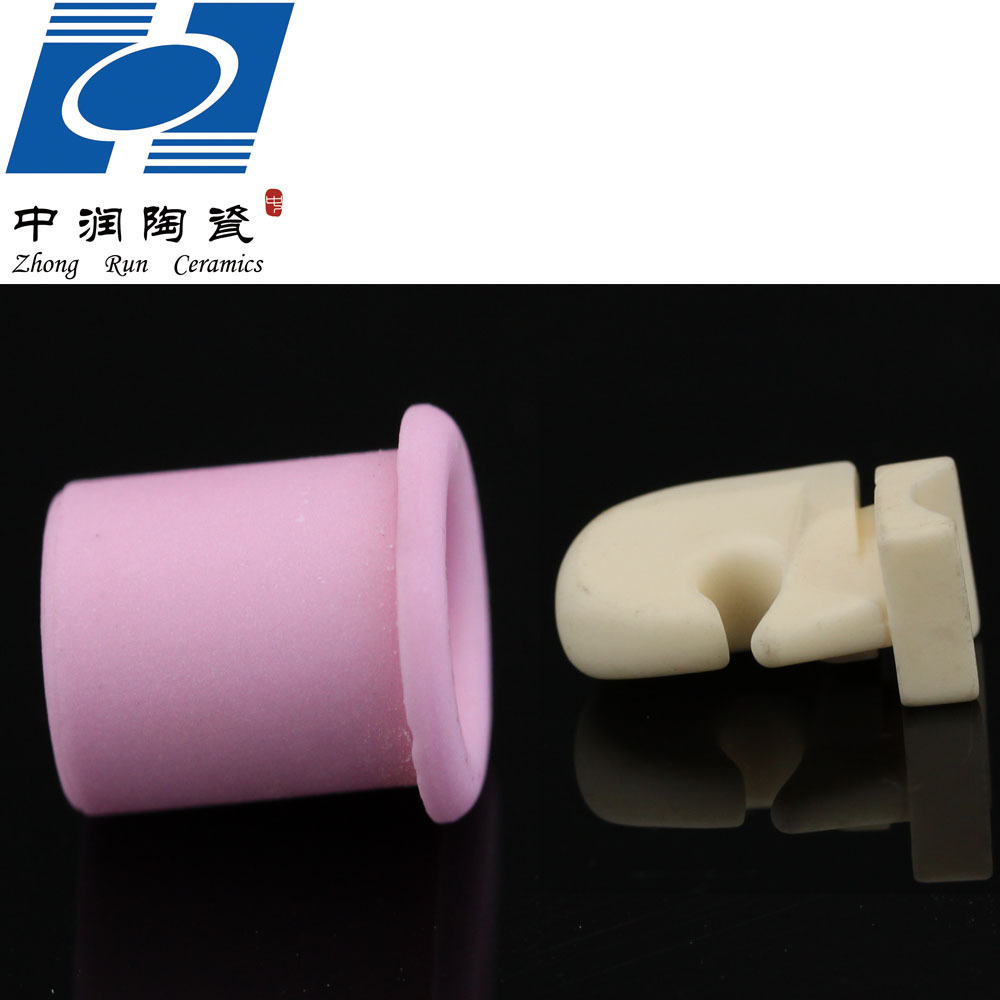

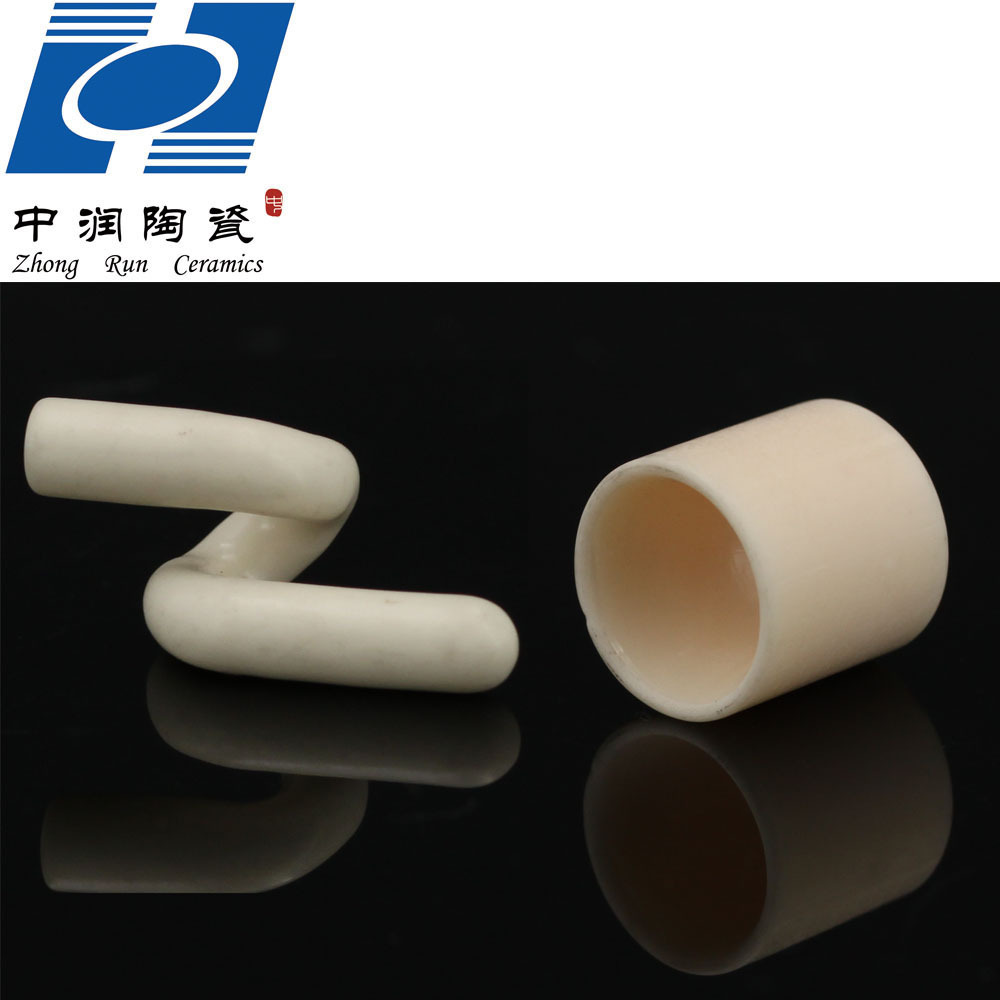

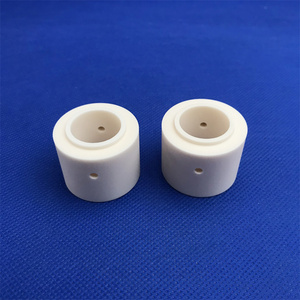

| Product name | textile ceramic parts |

| Place of Origin | Jiangsu, China(mainland) |

| Brand Name | Zhong Run |

| Type | Insulating Ceramics |

| Material | Alumina Ceramics |

| Color | White or Red or other color according to clients drawing |

| Size | Customzied |

| Shape | Custom-shaped |

| Producing Method | Hot pressing/Dry pressing |

| Design | Textile Ceramic |

| Payment | T/T, Western Union |

| MOQ | 10000pieces |

| Packing | Carton /Pallet/Wooden case (According to clients requirement) |

| Delivery time | Standard Product: Within 3 days |

| New developed items: 15days | |

| Application | Heating |

| Features | 1. Many kinds of insulated ceramics available |

| 2. It can satisfy constant's technical request | |

| 3. Good lead-heat capability | |

| 4. High resistance | |

| 5. High temperature and high voltage resistant |

textile ceramic parts selected raw materials

We manufactures custom technical ceramics, covering a wide range of customer requirements .We make use of several forming and machining techniques to process components made from alumina Ceramics.

| Steatite Ceramics Technical Parameter |

| Alumina Content | 80-85% | 90-96% | > 99.5% | 99% |

| General Application | Lower Cost Electrical & Mechanical | High Strength, Wear Resistant, Electronic, Insulating, Mechanical, Structural & Metalizing | Extremely High Purity, Temperature & Strength; Excellent Corrosion & Wear Resistance | Porous, Easily Degassed & Machinable |

|

Porosity (%) |

0-.05 | 0-.05 | 0-.05 | Variable |

|

Density (gm/cm3) |

3.45-3.50 | 3.55-3.75 | 3.75-3.95 | 2.4 |

| Flexural Strength (kpsi) | 35.0-40.0 | 40.0-50.0 | 50.0-55.0 | - |

|

Comprehensive Strength (kpsi) |

260.0 | > 300.0 | > 300.0 | - |

|

Tensile Strength (kpsi) |

15.0-20.0 | 20.0-28.0 | 20.0-28.0 | - |

|

Linear Coefficient of Thermal Expansion ((cm/cm/°C) 25-300°C 25-700°C) |

5.9X10-6 6.5X10-6 | 6.3X10-6 7.0X10-6 | 6.5X10-6 7.5X10-6 | 6.5X10-6 7.5X10-6 |

|

Dielecctric Constant at 25°C (1 MH 10 MH) |

8.5-8.9 8.4-8.8 |

9.2-9.8 9.0-9.6 | 9.5-9.9 9.3-9.7 | - |

|

Dielectric Strength (Volt/mil) |

200 | 225 | 225 | - |

|

Te Value (°F °C) |

1472 800 | > 1832 > 1000 | > 1832 > 1000 | > 1832 > 1000 |

| Thermal Conductivity at 25°C (cal/sec/cm2/cm/°C) | .03-.04 | .04-.06 | .07-.08 | - |

| Thermal Shock | Good | Good | Good | Good |

| Safe Use Temperature (°F °C) | 2550 1400 | 3000-3100 1650-1700 | 3275 1800 | 3275 1800 |

Technical process for producing textile ceramic part

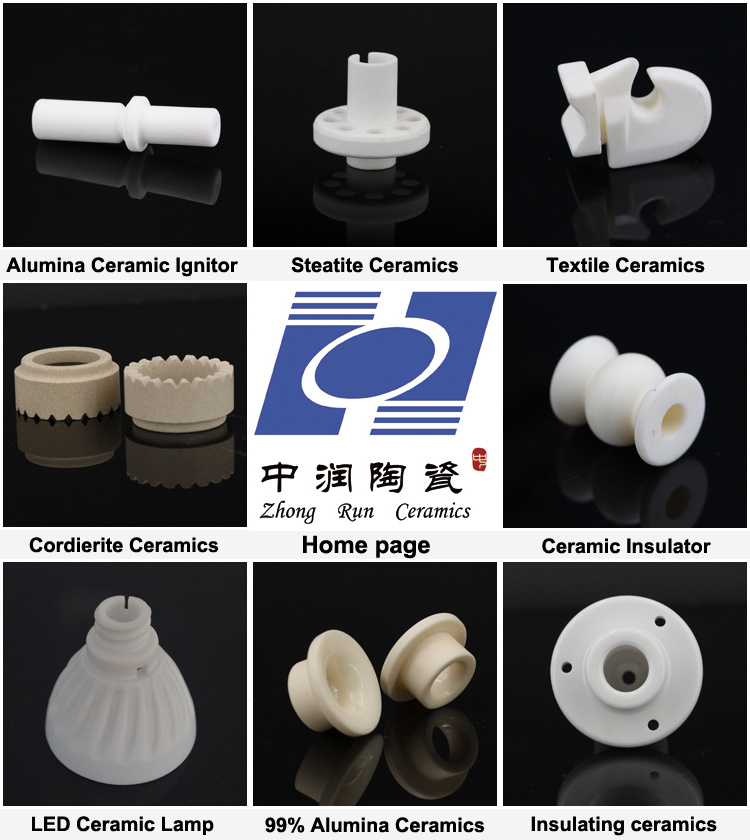

| Hot-selling Products |

| Main Raw Materials |

|---|

Alumina ceramics

Alumina Ceramic may be used in applications that require high elevated temperatures, High dielectric strength, excellent electrical resistance, wear or corrosion resistance, high temperature capability. High Electrical insulation.

Zirconia ceramics

Zirconia (ZrO2) is a unique advanced ceramic. Products manufactured from zirconia powder exhibit superior mechanical properties such as high strength and flexibility.

Steatite ceramics

Steatite is used to support heating elements in electric heaters, toasters, and ovens.

Steatite is a good high voltage insulator. It holds up under thousands of volts without breaking down.

Cordierite ceramics

The main chemical ingredient of cordierite ceramic is 2MgO·2Al2O3·5SiO2, main material is steatite, clay, alumina, feldspar, etc. Manufactured by normal ceramic technic, can be used for loop frame work, insulators of arc-resistance, element of composite materials, burnable nozzle of electrical insulators, etc.

|

Professional Industrial Ceramics Manufacturer

Nancy Yixing Zhong Run Ceramics Technology Co., Ltd

Add: Luojian Industrial .Dingshu.Yixing City ,Jiangsu Province .China Tel: +86-510-87490978 Fax: +86-510-87487578 Mobile: +86-13901533340 Web: www.zrceramics.com

|

|---|