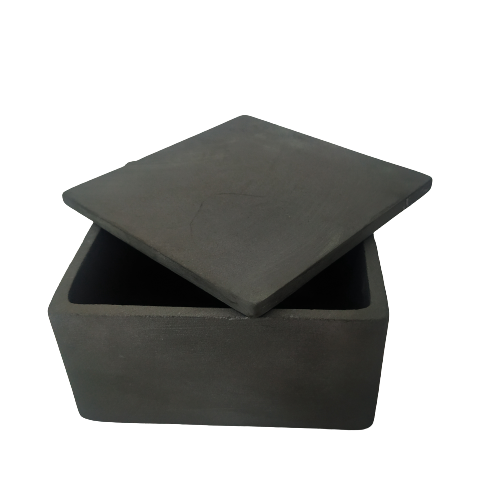

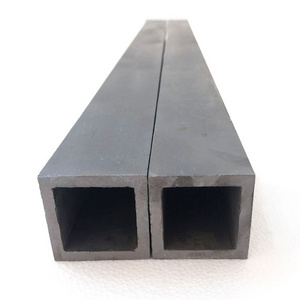

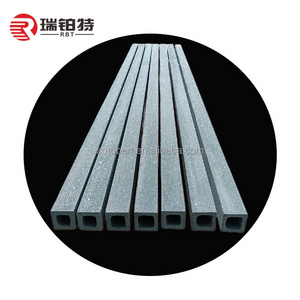

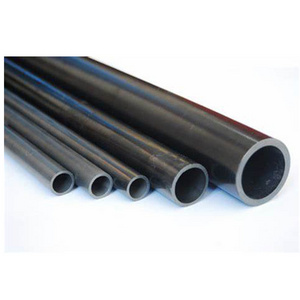

The silicon carbide ceramics crucibles and saggers can be used for various powder sintering, metal smelting, and the fields of metallurgy, chemical industry, glass and the like. Shandong ZHIJING is committed to R&D, production and sales of high-performance silicon carbide products. The main products are reaction sintered silicon carbide ceramic beams, roller bars, fire nozzles, cold air ducts, sheds, enamel, enamel, thermocouple protection Tube, heat exchange tube, radiant tube inner tube, radiant tube outer tube, desulfurization nozzle, cantilever paddle, atmosphere furnace tube, sand blasting nozzle, bushing, seal and various high temperature, wear and corrosion resistant silicon carbide ceramic shaped Piece, etc.